Hey gang,

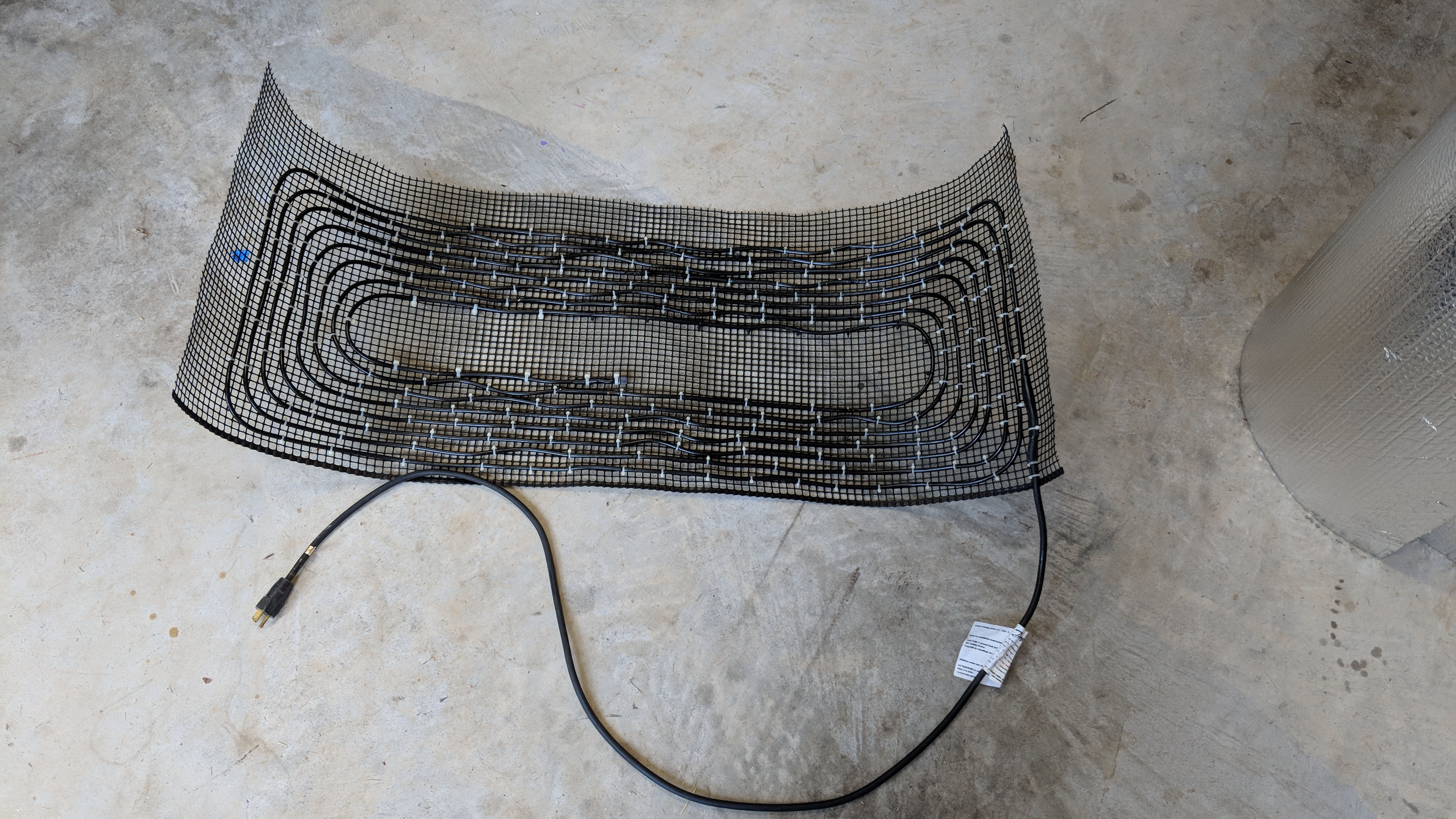

would it be possible to buy one of those ice-melt cables that you use on your roof eave to prevent ice build-up, put it on a rheostat, wrap it around the outside of a stainless-steel pot, set it in an insulated box and use it for temperature controlled mashing?

I'm growing weary of the picnic cooler approach - such a pain to hit and maintain temps, no good way to raise temp at mashout, etc.

If not a ice-melt cable, something else that might work?

would it be possible to buy one of those ice-melt cables that you use on your roof eave to prevent ice build-up, put it on a rheostat, wrap it around the outside of a stainless-steel pot, set it in an insulated box and use it for temperature controlled mashing?

I'm growing weary of the picnic cooler approach - such a pain to hit and maintain temps, no good way to raise temp at mashout, etc.

If not a ice-melt cable, something else that might work?