You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Huge E-HERMS build, 3 keggles, control panel, stir plate, ferm controller, 61 pics

- Thread starter azwillnj

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

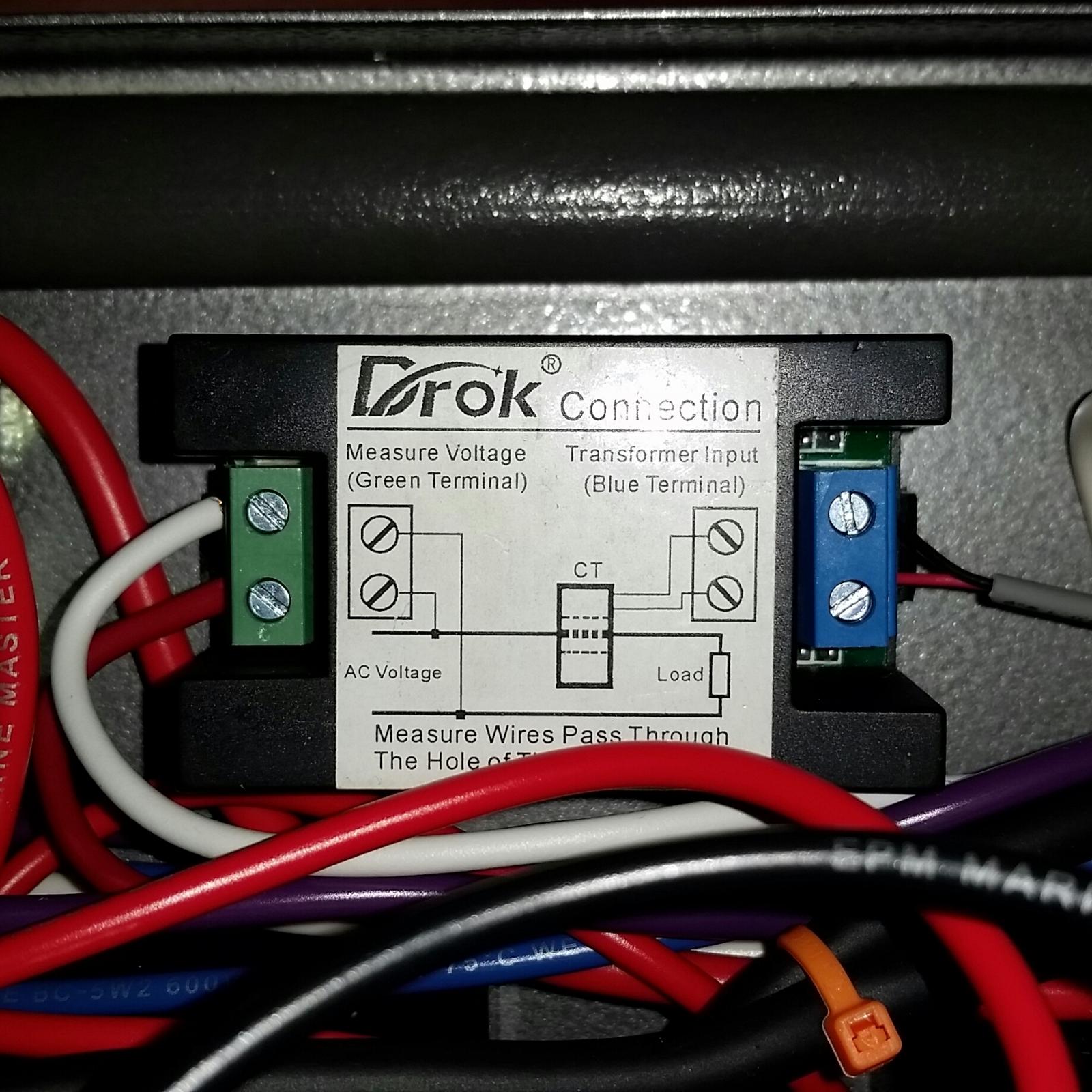

I figured it out with the meter. Your diagram shows hooking neutral and hot to the meter. My meter requires both hots to it.

I have 120v to each of my pump outlets. 240v to each element outlet. Figuring out the pids. Only have one probe ready so I have to finish the other 2.

Now on to the timer. It's not timing. Makes it a failure as a timer.

I have 120v to each of my pump outlets. 240v to each element outlet. Figuring out the pids. Only have one probe ready so I have to finish the other 2.

Now on to the timer. It's not timing. Makes it a failure as a timer.

Dfitz

Well-Known Member

Nice! I have one similar except a 20 gal. HERMS and my panel is 50amp w/an alternate system for another hobby I enjoy. No CFC?

You chilling via HERMS coil?

You chilling via HERMS coil?

Dfitz

Well-Known Member

Do you have photos?

I do but my goodies aren't as polished.

Somewhat in disarray as school is letting out here and I have kids helping me clean out my garage.

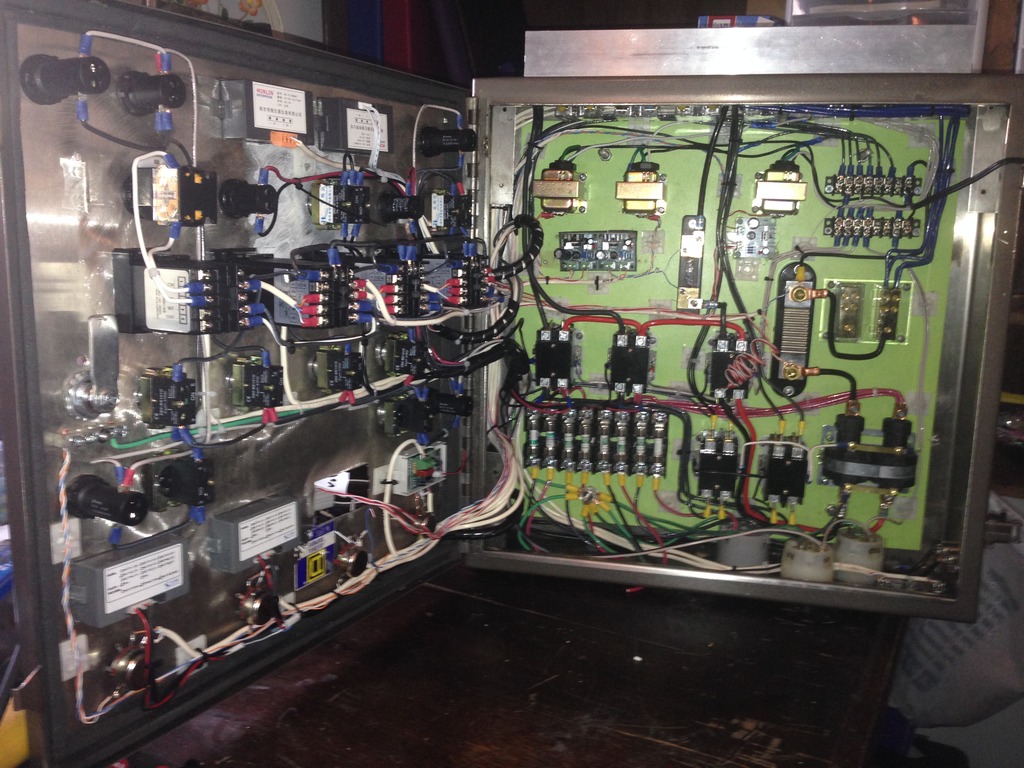

Panel serves two functions, one for brewing and the other not open for discussion.

My boil keg, as you can see by the bottom in the spirit of things I did attempt to polish a bit. No thanks! lol

Then there's my old crawfish pot HERMS, I had it on hand so its what I'll be using for a while. 40' of 1/2 tubing was a bear to roll to fit but it's expandable and really works well managing a mash temp. on a 25 gallon pot. (not shown). I hear people talk about recirculating their HERMS but I haven't noticed any issues.

I picked up a Pico false bottom for my mash tun. I think it'll work well.

Like I say, no bling and cleaning the garage so it'll be out of commission for a couple weeks while I re-organize and make more room. I have a fast ferment conical in a controlled freezer, stir plate ect. I really need to organize to fit another freezer.

I do need to clean things up a bit when I get them situated into a fitting position but I can probably assure you no polishing is in my plans. That's a young man's pleasure!

I decided to polish because of the original poster's (azwillnj) pictures. It's easy to clean too. I'm more middle aged and hated every minute of polishing, but my obsessive side took over. I'm glad I did. Did you build that panel? Very clean wiring job. I attempted to keep mine that organized but slowly lost control over tidiness. It's still way cleaner than others I've seen examples of though. I still have to trace the root of my problem with blowing the main breaker when I turn on my boil element. Gonna do some trouble shooting today.

So I found my problem. One of my ssr relays went bad. It doesn't make sense since I only fired it up to verify that everything worked prior to hooking up elements. It worked then but now it doesn't. So I ordered another and a back up. Hopefully that's it for replacing brand new stuff. Calibrated my sight glasses today too.

azwillnj

Well-Known Member

That looks awesome, great job! I like the tablet mount.

mbtech

Well-Known Member

Hey Alex. Very well done! You have inspired me to create an identical E-Herms system, but I have a couple questions:

1) What is the size or dimensions of the electrical junction box that you used?

2) Would you mind sharing the PP template you made for the cut outs? I have PM'ed you my email address.

3) What gauge wire do you recommend using? I am creating an exact copy of your build and don't plan on doing anything larger than 10 gal batches.

-Ryan

1) What is the size or dimensions of the electrical junction box that you used?

2) Would you mind sharing the PP template you made for the cut outs? I have PM'ed you my email address.

3) What gauge wire do you recommend using? I am creating an exact copy of your build and don't plan on doing anything larger than 10 gal batches.

-Ryan

Hey Alex. Very well done! You have inspired me to create an identical E-Herms system, but I have a couple questions:

1) What is the size or dimensions of the electrical junction box that you used?

2) Would you mind sharing the PP template you made for the cut outs? I have PM'ed you my email address.

3) What gauge wire do you recommend using? I am creating an exact copy of your build and don't plan on doing anything larger than 10 gal batches.

-Ryan

My box is 16x16x6. While wiring I wish it was bigger but it turned out great. I added a timer so I needed the extra space.

I used 10awg for all load bearing and 14awg for everything else.

I just laid it out according to what looked good.

mbtech

Well-Known Member

My box is 16x20x6. While wiring I wish it was bigger but it turned out great. I added a timer so I needed the extra space.

I used 10awg for all load bearing and 10awg for everything else.

I just laid it out according to what looked good.

Awesome, thanks for the info! I'll keep you updated on my build.

mbtech

Well-Known Member

I'm looking for the mechanical relays and was wondering if this will work here: http://www.ebay.com/itm/1-2-5-10-pc...hash=item2815826d56:m:m06xO46RVicqqw-Suj4ZcXQ

http://www.ebay.com/itm/MAGNECRAFT-...301626?hash=item4d249625ba:g:te0AAOSwXeJXdAOH

This is the one I used. Not sure which configuration you are looking at since there are options on the listing.

This is the one I used. Not sure which configuration you are looking at since there are options on the listing.

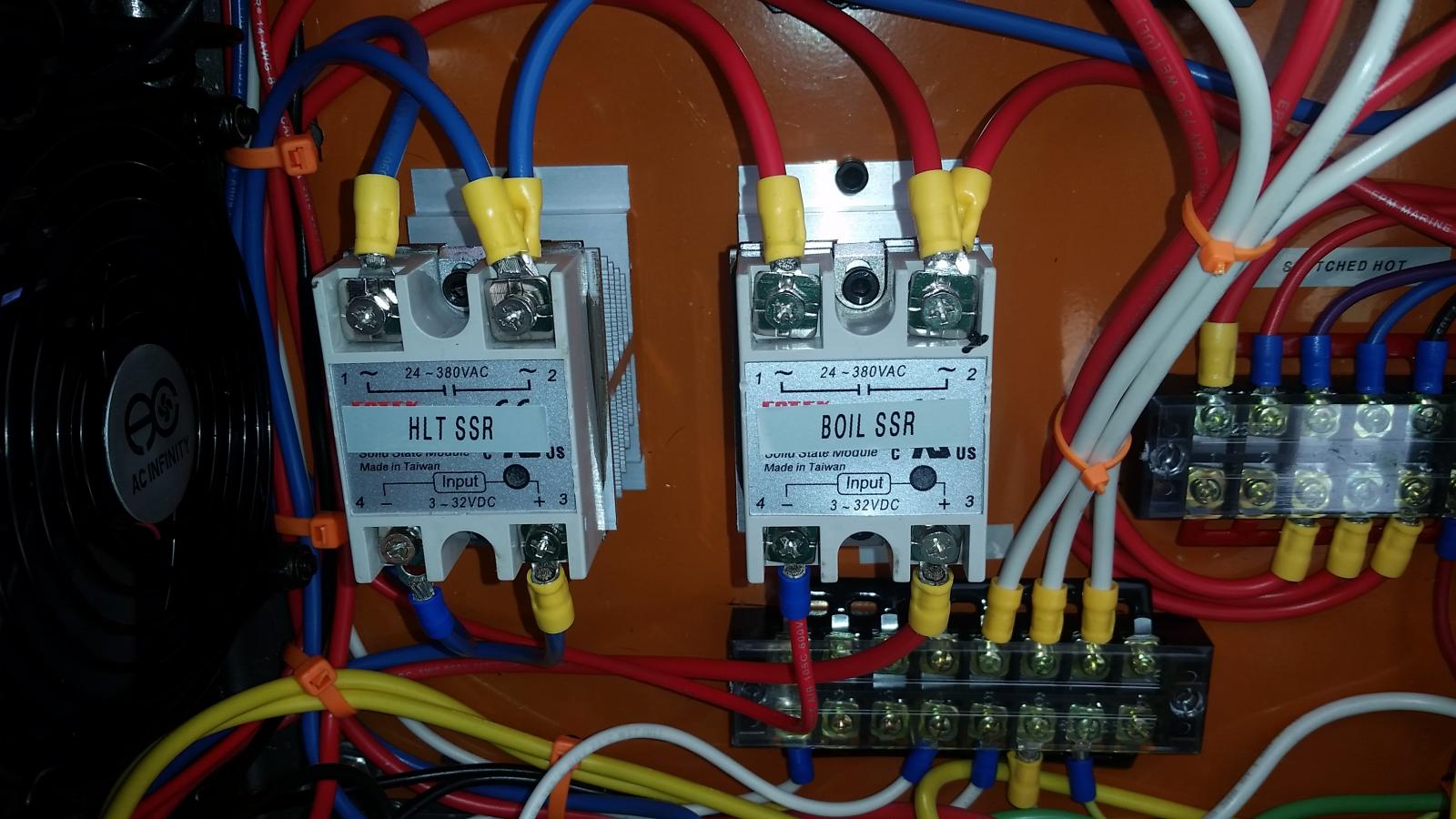

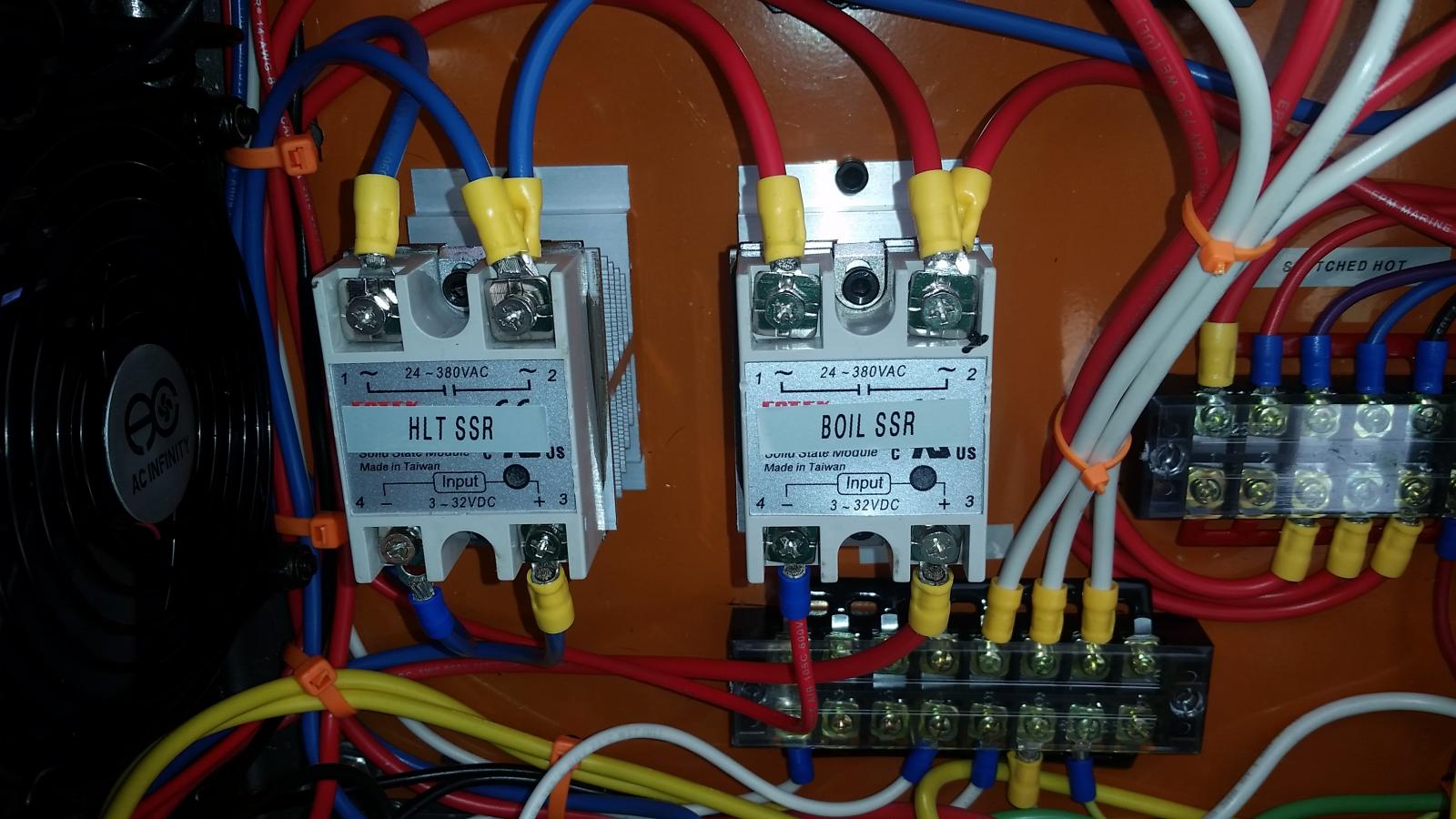

Alex has some differences in his design from mine but since I saw your post I decided to answer your questions according to my build. He will respond I'm sure. He was a huge help with info for my build. For my ssr I originally purchased a Fotek 240v ssr with a heat sink. It worked for all dry runs (without load) but one of them failed under load. I got it replaced by the company but I also bought another set of a different brand as a backup. They are reported to be hit or miss. I followed Alex's suggestions of what he would do different, as well, with the pids. I got all 3 from Auber and all the same model syl-2352.

http://www.auberins.com/index.php?main_page=product_info&cPath=1&products_id=3

And the timer I used was also from Auber. It has settings for up to 9 additions with alarms.

http://www.auberins.com/index.php?main_page=product_info&cPath=16&products_id=356

I did make some other minor changes to my layout. My cords plug into the bottom. It just works better for my mount which is a TV mount rated to 50lbs. I also added a computer fan and cut slots in the side of the box for air flow. I don't know if it's necessary but I knew that it wouldn't hurt to try to keep it cool with outside air.

For my keggle hardware I got almost everything from Bobby at brewhardware.com great guy and very helpful. Excellent fittings. Especially the pull through bulkheads. Very clean. His element enclosures make for a clean port also. He has videos for all of his parts showing you how to best install them.

I could go on forever. Don't hesitate to ask.

http://www.auberins.com/index.php?main_page=product_info&cPath=1&products_id=3

And the timer I used was also from Auber. It has settings for up to 9 additions with alarms.

http://www.auberins.com/index.php?main_page=product_info&cPath=16&products_id=356

I did make some other minor changes to my layout. My cords plug into the bottom. It just works better for my mount which is a TV mount rated to 50lbs. I also added a computer fan and cut slots in the side of the box for air flow. I don't know if it's necessary but I knew that it wouldn't hurt to try to keep it cool with outside air.

For my keggle hardware I got almost everything from Bobby at brewhardware.com great guy and very helpful. Excellent fittings. Especially the pull through bulkheads. Very clean. His element enclosures make for a clean port also. He has videos for all of his parts showing you how to best install them.

I could go on forever. Don't hesitate to ask.

mbtech

Well-Known Member

Alex has some differences in his design from mine but since I saw your post I decided to answer your questions according to my build. He will respond I'm sure. He was a huge help with info for my build. For my ssr I originally purchased a Fotek 240v ssr with a heat sink. It worked for all dry runs (without load) but one of them failed under load. I got it replaced by the company but I also bought another set of a different brand as a backup. They are reported to be hit or miss. I followed Alex's suggestions of what he would do different, as well, with the pids. I got all 3 from Auber and all the same model syl-2352.

http://www.auberins.com/index.php?main_page=product_info&cPath=1&products_id=3

And the timer I used was also from Auber. It has settings for up to 9 additions with alarms.

http://www.auberins.com/index.php?main_page=product_info&cPath=16&products_id=356

I did make some other minor changes to my layout. My cords plug into the bottom. It just works better for my mount which is a TV mount rated to 50lbs. I also added a computer fan and cut slots in the side of the box for air flow. I don't know if it's necessary but I knew that it wouldn't hurt to try to keep it cool with outside air.

For my keggle hardware I got almost everything from Bobby at brewhardware.com great guy and very helpful. Excellent fittings. Especially the pull through bulkheads. Very clean. His element enclosures make for a clean port also. He has videos for all of his parts showing you how to best install them.

I could go on forever. Don't hesitate to ask.

Ok, I'll keep asking

That one will work. However, you will need to unscrew it everytime you want to really clean. I used this one with a triclover clamp. The element is sealed in a housing. The one you posted is probably easier to solder since it actually sits in the hole. But if you can follow Bobby's video instructions you won't have any major issues.

https://www.brewhardware.com/product_p/etc4s.htm

https://www.brewhardware.com/product_p/etc4s.htm

mbtech

Well-Known Member

Ok, that's really neat! I'll probably just order the TC setup. Thanks for the info.

azwillnj

Well-Known Member

Sorry for my lack of replies, its been a busy week. Here are answers to your questions and some random thoughts:

I'm sure I'll think of some other stuff, I'll post it when I do.

Let me know if you have any other questions.

Alex.

- I sent you the template for the front and the power panel. I have everything in photoshop and i can send those psd files over if you want.

- If I were doing this again like Beerinnj mentioned I would go with all Auber PID's and actually, I would go with Auber's new boil control thing for the boil kettle. http://www.auberins.com/index.php?main_page=product_info&products_id=444

- I don't think a timer on the panel is worth it, but thats just me. I would much rather use BeerSmith on my phone.

- I agree with Beerinnj, get that tricolver thing for the element. I am actually using that exact one on my eBIAB system I am making for my apartment.

- I would put TC fittings wherever I could on the kettle, it would make cleaning so much easier. Thats what I'm doing on my new system, TC's for everything that connects to the kettle.

- I am also using the ball lock QC's for the tubing this time, the Cam Lock ones are kinda difficult to use.

- I didn't put a valve on the top tube in the HLT assuming that I would never have the water that high. I should not have done that, when doing a 10gal batch I wasn't paying attention once and the water was over the port and started spewing out 170F water when I took the QC off, haha. Put a valve on everything that penetrates the kettle.

- Plate chillers are awful, just don't. I am making a counterflow out of a garden hose and copper tubing right now, I expect that to work much better. Using the HERMS coil to chill the batch is not very effective either. It takes a very long time.

- Try to angle the ports in your kettle a little so when you pop the QC off whatever is in the fitting is pulled back into the kettle with gravity. I accidentally did this on one of my fittings, only like 2-3 degrees of tilt and I wish I had done it to all of the soldered fittings.

- If you are going with keggles like me, save the top after you cut it off. With a little welding you could make it into a nice little dome to direct vapor into other things........... for reasons.

- Buy some extras of stuff, maybe one relay, ssr, some contactor blocks... You never know when these cheap Chinese components might let the magic smoke out, you wouldnt want a batch ruined over an $8 relay.

I'm sure I'll think of some other stuff, I'll post it when I do.

Let me know if you have any other questions.

Alex.

jcc4507fly

Well-Known Member

- Joined

- Dec 27, 2012

- Messages

- 191

- Reaction score

- 17

Ok, that's really neat! I'll probably just order the TC setup. Thanks for the info.

Here is another option made of all stainless. I have two of them and I'm glad I went this route. It is thicker gauge than the brewhardware one. Designed so you can use it with either straight or ripple elements. It is heavy duty and made well.

http://www.brewershardware.com/2-Tri-Clover-X-1-NPS-Element-Adapter.html

It also comes in 1.5".

http://www.brewershardware.com/TC15F10NPSCOV.html

http://www.brewershardware.com/images/D/TC20EEA-D2.jpg

mbtech

Well-Known Member

Thanks again for everyone's input on this. I received my 16x16x8 junction box today and it looks really good. However, it did not come with the back plate that goes on the inside which my relays, heatsinks, ect. will attach to. Does anyone know what this plate is actually called, and where can I find one? I've been searching high and low without any luck. Hopefully I can find one and assume it is non-metallic so it doesn't conduct electricity...but not sure.

azwillnj

Well-Known Member

Thanks again for everyone's input on this. I received my 16x16x8 junction box today and it looks really good. However, it did not come with the back plate that goes on the inside which my relays, heatsinks, ect. will attach to. Does anyone know what this plate is actually called, and where can I find one? I've been searching high and low without any luck. Hopefully I can find one and assume it is non-metallic so it doesn't conduct electricity...but not sure.

That's strange it didn't come with the panel, are the studs there to mount one? You should contact the seller to see if they just forgot it.

It's actually pretty thick gauge steel, very heavy. I suppose if you had to you could go over to home depot and get a piece of either steel or lexan to put in there and make one yourself.

Alex.

Thanks again for everyone's input on this. I received my 16x16x8 junction box today and it looks really good. However, it did not come with the back plate that goes on the inside which my relays, heatsinks, ect. will attach to. Does anyone know what this plate is actually called, and where can I find one? I've been searching high and low without any luck. Hopefully I can find one and assume it is non-metallic so it doesn't conduct electricity...but not sure.

Mine came with one too. It was bright orange. Still is. It's thick enough that I tapped it to mount my relays instead of using nuts.

mbtech

Well-Known Member

That's strange it didn't come with the panel, are the studs there to mount one? You should contact the seller to see if they just forgot it.

It's actually pretty thick gauge steel, very heavy. I suppose if you had to you could go over to home depot and get a piece of either steel or lexan to put in there and make one yourself.

Alex.

Well, I called the Ebay seller and they said it doesn't come with a plate, although they did paint it black with heavy duty paint. They wanted another $30 plus shipping for the backing plate!! Haha, no thanks. My neighbor deals in aluminum and said he could get me a plate for free. I'll start adding some pictures soon as I already have all the holes cut in the box and hope to start adding the lights, switches, PID, and wiring this weekend.

mbtech

Well-Known Member

Mine came with one too. It was bright orange. Still is. It's thick enough that I tapped it to mount my relays instead of using nuts.

Good idea on tapping the threads, although I'm not sure I want to spend that much time. Besides, my plate will be aluminum most likely and I don't know if I can put enough torque on the screws without stripping the threads in the plate. I do like that bright orange color though!

mbtech

Well-Known Member

Ok. Just finished building my junction box, wiring up the garage for 220v, installing a GFI 30 amp breaker, and powered this thing up. Something odd happened here, which is my fault for not understanding the wiring diagram. Here are some updates to where I'm at:

1. I found a 1/2" aluminum plate for the back mounting plate inside the junction box. I ended up tapping the holes for all the components as I realized it would be a nightmare to replace a single component if everything was attached with nuts and bolts.

2. I decided to install two Auber SLY-2352 and one DSPR120.

3. I ordered two Hot Pods with TC fittings from BrewHardware for the heating elements.

4. Powered up the box for the first time, and noticed all three LEDs were lit for the HLT, Mash, and Boil PID. Upon closer examination of the wiring diagram and looking at the pictures Alex provided on the inside of his door, I realized that he has stacked dual contactors (total of four) for the element power switch, PID select switch, and element select switch. Unfortunately, I thought there were only two total contactors on each of these switches and that the wiring diagram was drawn this way for easier viewing. The extra contactors are now on order and will arrive soon. However, I did power this thing on and hopefully I didn't damage anything. I didn't see smoke, nothing smells burnt, the PIDs did turn on. Fingers crossed.

1. I found a 1/2" aluminum plate for the back mounting plate inside the junction box. I ended up tapping the holes for all the components as I realized it would be a nightmare to replace a single component if everything was attached with nuts and bolts.

2. I decided to install two Auber SLY-2352 and one DSPR120.

3. I ordered two Hot Pods with TC fittings from BrewHardware for the heating elements.

4. Powered up the box for the first time, and noticed all three LEDs were lit for the HLT, Mash, and Boil PID. Upon closer examination of the wiring diagram and looking at the pictures Alex provided on the inside of his door, I realized that he has stacked dual contactors (total of four) for the element power switch, PID select switch, and element select switch. Unfortunately, I thought there were only two total contactors on each of these switches and that the wiring diagram was drawn this way for easier viewing. The extra contactors are now on order and will arrive soon. However, I did power this thing on and hopefully I didn't damage anything. I didn't see smoke, nothing smells burnt, the PIDs did turn on. Fingers crossed.

#1 that's the reason I tapped mine as well. It would be impossible to take the back plate out to get nuts off of any components. I thought about putting the bolts in backwards with a nut spacer so it was like a stud but realized tapping was easier.

#3 the hot pods are nice. Very clean look.

#4. Haha. I did the same thing and thought the same thing about Alex's diagram. I figured out what I did wrong and ordered a bunch of contactors. I think you'll be fine since you didn't have a load on it. You were only using half of the power.

Looks great.

The fun states when you power it up with heating elements attached. That's when it tests all of your relays & your wiring. I ordered 3 extra ssr relays (2 different brands) & 2 extra mechanical relays. I had one ssr burn out the first time I put a load on it. No problems since. But I think that's only because I have spare parts.

Also, download the pid user guides. It will have the listing of codes for the different temp probes. Mine had to be set on 21. But there are a lot of different styles. Mine screw into a 1/2" spud or bulkhead. Others are smaller threads and tougher to match up without different thread options.

#3 the hot pods are nice. Very clean look.

#4. Haha. I did the same thing and thought the same thing about Alex's diagram. I figured out what I did wrong and ordered a bunch of contactors. I think you'll be fine since you didn't have a load on it. You were only using half of the power.

Looks great.

The fun states when you power it up with heating elements attached. That's when it tests all of your relays & your wiring. I ordered 3 extra ssr relays (2 different brands) & 2 extra mechanical relays. I had one ssr burn out the first time I put a load on it. No problems since. But I think that's only because I have spare parts.

Also, download the pid user guides. It will have the listing of codes for the different temp probes. Mine had to be set on 21. But there are a lot of different styles. Mine screw into a 1/2" spud or bulkhead. Others are smaller threads and tougher to match up without different thread options.

JaywalkerDenmark

JaywalkerDenmark

I can see several people have asked before, seems they have a hard time finding it too (if it is available) ?

Is there any complete part list, especially for the control panel we could see please?

Very inspiring build, hope I can build it here in Europe too...

/Cheers

Is there any complete part list, especially for the control panel we could see please?

Very inspiring build, hope I can build it here in Europe too...

/Cheers

JaywalkerDenmark

JaywalkerDenmark

I can see several people have asked before, seems they have a hard time finding it too (if it is available) ?

Is there any complete part list, especially for the control panel we could see please?

Very inspiring build, hope I can build it here in Europe too...

/Cheers

Ok I found it ! No worries

mbtech

Well-Known Member

View attachment ImageUploadedByHome Brew1485139480.944103.jpg

It's been a while, sorry for the the late update. The system has been working flawlessly and beautifully. I often think about what I would change if I could do it differently, but I have no complaints. Since my last post, I've pumped out around 80 gallons so far. View attachment ImageUploadedByHome Brew1485139700.044500.jpgView attachment ImageUploadedByHome Brew1485139907.562634.jpg

It's been a while, sorry for the the late update. The system has been working flawlessly and beautifully. I often think about what I would change if I could do it differently, but I have no complaints. Since my last post, I've pumped out around 80 gallons so far. View attachment ImageUploadedByHome Brew1485139700.044500.jpgView attachment ImageUploadedByHome Brew1485139907.562634.jpg

Attachments

Similar threads

- Replies

- 2

- Views

- 358

- Replies

- 2

- Views

- 354

- Replies

- 14

- Views

- 1K

- Replies

- 0

- Views

- 488