first 24 hours... Oxygen = good

beyond that... Oxygen = bad

don't shake it doug.

+1

first 24 hours... Oxygen = good

beyond that... Oxygen = bad

don't shake it doug.

JeepDiver said:Using my Chiller, I move it up and down to quciken the chill, and move it around a lot. It's usually foamy by the time I get through. Never had a problem with stuff fermenting out. I may get some improvment with an O2 kit, but don't see the point right now since things come out good without it.

"It is generally safe to assume that you need at least 10ppm of oxygen. 10ppm will supply adequate oxygen in most situations. Over-oxygenation is generally not a concern as the yeast will use all available oxygen within 3 to 9 hours of pitching and oxygen will come out of solution during that time as well. Under-oxygenation is a much bigger concern."

This is directly from Wyeasts document. Regular air at max, no matter what method you use will only achieve at most, 8ppm. That is why Williams O2 system is important. If you haven't read this document, I highly suggest it. It's well done and easy to understand. I think an earlier poster has a link to it.

TimpanogosSlim said:With all due respect to the microbiologists at Wyeast, I think it's manifestly obvious that their writing staff have taken liberties with the word "need".

...I'm not sure I understand. Would there be a benefit for the microbiologists at Wyeast to them telling the consumer they need to use more oxygen? I don't see a motive there for them to mislead their consumers...are there other studies that have been published that indicate a different ppm level is most critical for yeast health? I certainly don't want to just take one source as gospel if something else may have a different, thoughtful theory.

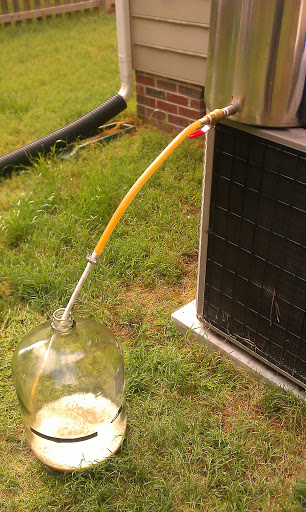

Full disclosure...I just purchased the Williams brewing system(haven't even received it yet) prior to that I put a tennis ball under my carboy and rolled it around on that for a good few minutes. Got decent results, but to take my beer to the next level, I'm looking to increase the health of my yeasties.

TimpanogosSlim said:It's abundantly clear that the majority of Wyeast's customers are successfully brewing with 8ppm or less.

So the word "need" here is perhaps a bit strong.

vtchuck said:I have an oxygen stone set-up, but only use it for really big beers or with lager yeast.

All the time; I only aerate when using liquid yeast. Works good for me.From the Danstar Catalog & Technical Info: There is no need to aerate wort when pitching with dry yeast. Due to a specific growth process, dry yeast already contains sterols and unsaturated fatty acids in the cell membranes and is ready to divide without any additional oxygen. However, if the yeast is reused, oxygenation will be required to ensure cell division. I always aerate to be on the safe side. Has anybody tried dry yeast without aerating?

I've been known to use the olive oil trick in larger beers and sometimes in starters. That seems to work pretty well IME.

Dan said:I've heard this somewhere before, well obviously here on HBT. Any idea "why" it works? In laymen's term please.

Edit: Here's the thread I was thinking of. I'm rereading it now. https://www.homebrewtalk.com/f13/using-olive-oil-instead-oxygen-47872/

winvarin said:I used it once and did not really notice any difference vs. a non- aerated fermentation. Certainly not enough data to disprove it.

However, I did notice an improvement in lag time and reduction in off flavors and aromas. That being said, I did start aerating at the same time I bought a stir plate and using Jamils calculator to bump my pitching rates closer to his recommendations. I even give my starter wort a quick blast of O2 before pitching the initial yeast pack.

All the time; I only aerate when using liquid yeast. Works good for me.

Enter your email address to join: