Been an HBT lurker for a very long time and have been watching this thread for a while. I purchased the 15gal HG system in Nov. of 2018 (Happy New Year!). I finished up my second brew on this system today. The first brew went pretty well but today's was different. I ran into the mash issues that others have described in this thread.

A couple equipment notes: I use a steam condenser since I brew in my basement and didn't want to bother with installing in a vent hood. The sprayer for recirc on the lid is the old plastic type that produces the circular spray pattern (maybe HG switched back to the old style?).

First I'll share my recipe for the first beer, a simple helles, in case any are interested or may find it useful (BrewersFriend):

https://www.brewersfriend.com/homebrew/recipe/embed/714612

The helles had no mash issues, but was low on OG, around 1.035, and had 1gal more than expected going into the fermentor (6.5 gal as opposed to 5.5gal). The high volume could be related to a lower boil off rate owing to the steam condenser in addition to the fact that I way overestimated the strike temp and had to bring down the temperature of the mash using cool water. Anyway, this beer turned out super delicious. Very happy with it. Worth emphasizing that the mash was pretty thin.

The IPA I brewed today had the stuck recirc issue others have reported. Here's the recipe:

https://www.brewersfriend.com/homebrew/recipe/embed/724236

I did a few things different with this recipe that I suspect were contributing factors, which are as follows:

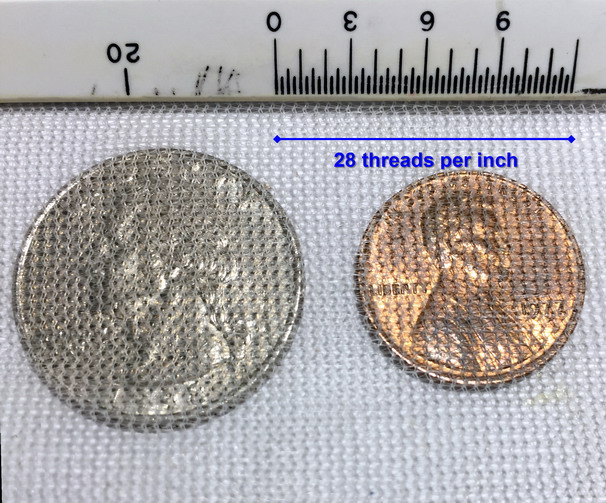

- I usually crush at 0.04 to 0.045. I adjusted my mill (Cereal Killer) today to credit card width which ended up being something like 0.03 to 0.035. I did this to try and boost the efficiency.

- This grain bill had 1.5lbs of wheat malt. I'm sure that didn't help.

- I started with 7.1gal instead of the 8gal of water for full volume mash. I did this since I had ended with such a large discrepancy in volume on the first batch. This yielded a much thicker mash.

I ended up turning the sprayer recirc off and just moved the hose to the lower whirlpool port. I turned the heat off at one point as well (prior to switching to the whirlpool). I did this as it was clear that the water was piling up on the grain bed and left coil exposed to air (or so I suspected). Moving to the whirlpool port stabilized the temps but the grain bed stayed much cooler than desired as measured by a separate temp probe located in the middle of the grain (142F). The OG ended up around 1.061 (expected 1.066) and I got 4.5 gal in the fermentor (expected 5.5gal). So I way overcorrected on the volume issue and didn't move the needle on the low OG. Pre-boil gravity was about 1.055. Perhaps lower boil off rate from the steam condenser played a role and I didn't add cool water to mash to correct an overshot strike temp. I'm sure the mash troubles didn't help either.

Based on this thread, I think I'll do the following for my next brew (an ESB):

- Switch the grain mill back to 0.04-0.045.

- Malt conditioning + rice hulls

- Revert back to whatever BrewersFriend's water calculator suggests for water volume.

The ESB has a grain bill less prone to sticking things up, so I'm less concerned there. But the efficiency is something I'd like to improve. I can always add more grain to compensate, but if that boosts the odds of the mash issue then it's something I would prefer to avoid.

Anyway - just wanted to share my experience so far! I think my issues are largely operator-error. I'm optimistic I/we will get our systems dialed in. Maybe sharing some recipes we've had success as well as trouble with would help?

Alright I'll end my novel here