eon

Well-Known Member

Hello all. I just bought an Igloo round 5 gallon cooler. I also bought all of the parts in Fly guys "!0 gallon Rubbermaid" instructional:

Here is the cooler. Not exactly the same design on the front as mine but I think it is the exact same cooler:

http://cgi.ebay.com/Igloo-42316-5-Gallon-Seat-Top-Beverage-Cooler-Orange-/270600434576

- Rubbermaid 10 gallon round beverage cooler

- all stainless steel ¼ hose clamps x 2

- brass square head plug (Watts A-737)

- ½ x 12 (or larger) braided stainless steel supply hose

- 3/8 female barb adapter (Watts A-298)

- 5/8 stainless steel fender washer (sometimes hard to find, but try Fastenal or read this thread if you are stuck)

- 3/8 MIP x 1-1/2 brass nipple (Watts A-786)

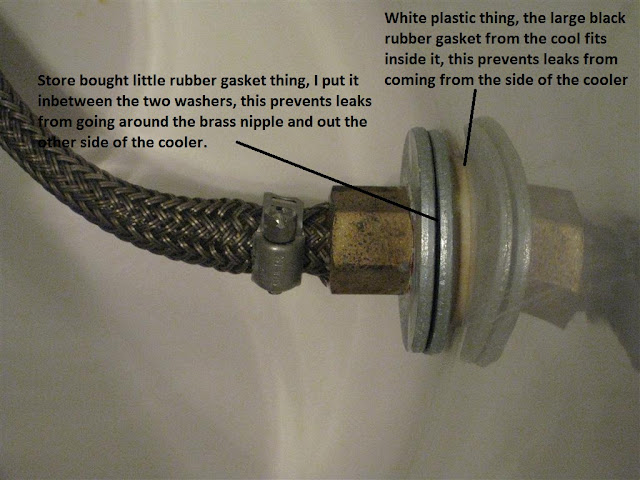

- seal from plastic spigot of cooler (shown below)

- Teflon tape (note: everything to the left of the tape in the picture above goes inside the cooler, and everything to the right goes outside)

- 5/8 O-ring (preferably heat resistant, if you can find one)

- 3 x 5/8 fender washers

- 3/8 threaded ball valve

- 3/8 male barb adapter (Watts A-294)

I am having some trouble. I don't know If I bought the wrong size parts or what but the brass nipple is WAY smaller than the hole on the cooler. Is this supposed to be like this?

Not really sure how to put this thing together.

If anyone wants to help, I would appreciate it. We can message back and forth on here or somewhere else.

I want to attempt putting this together before I run back to home depot and exchange the parts.

One thing, I noticed was that the ball valve is unable to open and close because the cooler body is in the way.

Hope this isnt turning into a nightmare!

Well, I took pictures of everything. Just ask, if you would like to see anything,

Thanks!

Here is the cooler. Not exactly the same design on the front as mine but I think it is the exact same cooler:

http://cgi.ebay.com/Igloo-42316-5-Gallon-Seat-Top-Beverage-Cooler-Orange-/270600434576

- Rubbermaid 10 gallon round beverage cooler

- all stainless steel ¼ hose clamps x 2

- brass square head plug (Watts A-737)

- ½ x 12 (or larger) braided stainless steel supply hose

- 3/8 female barb adapter (Watts A-298)

- 5/8 stainless steel fender washer (sometimes hard to find, but try Fastenal or read this thread if you are stuck)

- 3/8 MIP x 1-1/2 brass nipple (Watts A-786)

- seal from plastic spigot of cooler (shown below)

- Teflon tape (note: everything to the left of the tape in the picture above goes inside the cooler, and everything to the right goes outside)

- 5/8 O-ring (preferably heat resistant, if you can find one)

- 3 x 5/8 fender washers

- 3/8 threaded ball valve

- 3/8 male barb adapter (Watts A-294)

I am having some trouble. I don't know If I bought the wrong size parts or what but the brass nipple is WAY smaller than the hole on the cooler. Is this supposed to be like this?

Not really sure how to put this thing together.

If anyone wants to help, I would appreciate it. We can message back and forth on here or somewhere else.

I want to attempt putting this together before I run back to home depot and exchange the parts.

One thing, I noticed was that the ball valve is unable to open and close because the cooler body is in the way.

Hope this isnt turning into a nightmare!

Well, I took pictures of everything. Just ask, if you would like to see anything,

Thanks!