kennyconley0269

Active Member

- Joined

- Sep 11, 2022

- Messages

- 40

- Reaction score

- 14

Hey all,

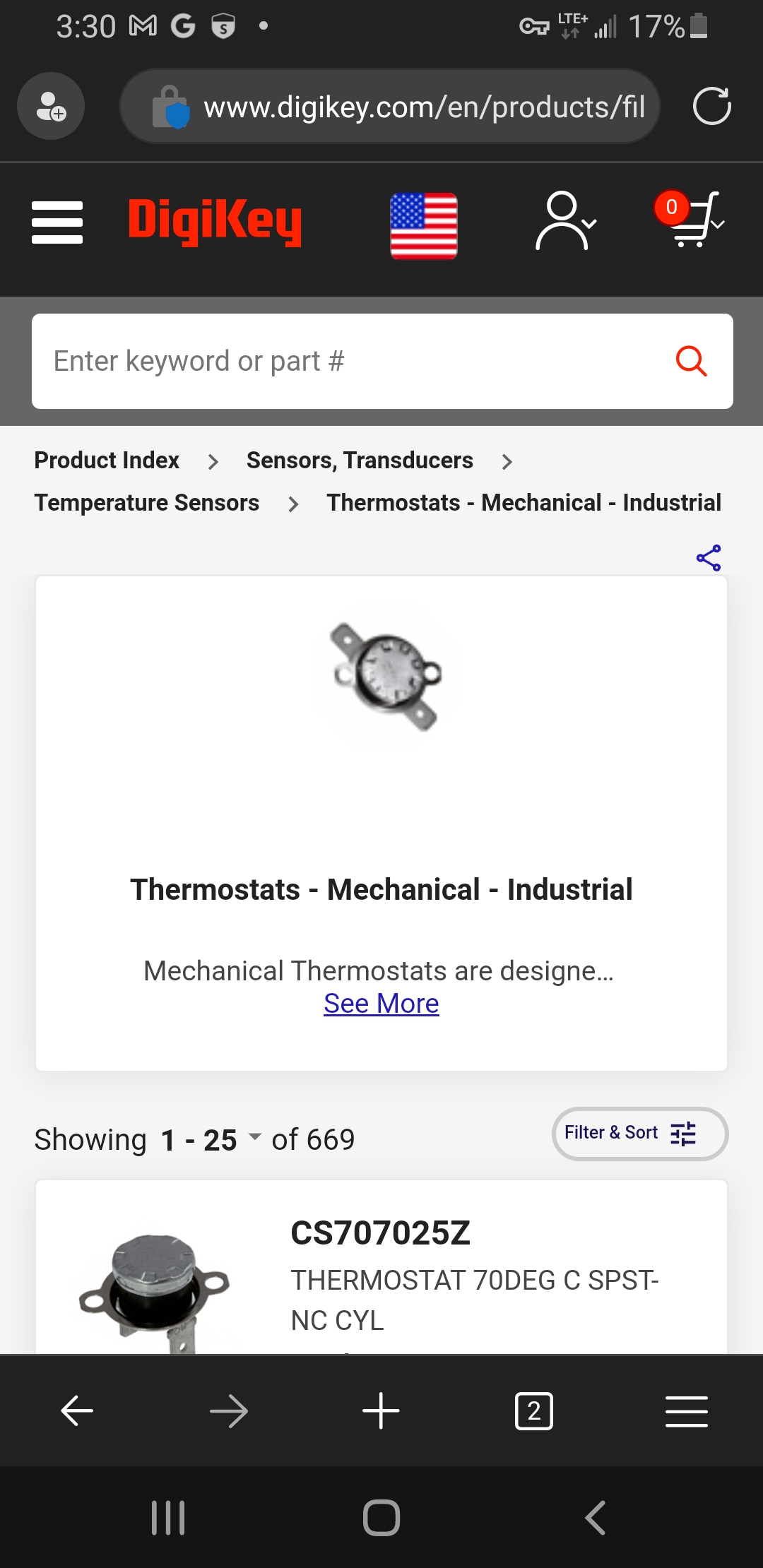

Does anyone have experience fixing these brew kettles? The manufacturer has been zero help. This component has fried a couple times now and I don’t know what it is or where I might be able to source a new one… Or why it keeps frying for that matter.

Thanks

Does anyone have experience fixing these brew kettles? The manufacturer has been zero help. This component has fried a couple times now and I don’t know what it is or where I might be able to source a new one… Or why it keeps frying for that matter.

Thanks