Hey everyone. Have a broken weld on my CF30 chiller coil. Long story short, about 2 cups of 50/50 glycol/water mix got into 40 gallons. I believe that it’s garbage but wanted to verify. This needs to be dumped correct?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Glycol got in beer

- Thread starter Rob2010SS

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Yeah it’s propylene glycol. The food grade stuff.I would dump it but if your using propylene glycol it’s not actually poisonous. They even put it in ice cream.

Does it affect the taste much?Yeah it’s propylene glycol. The food grade stuff.

Haven’t tasted it. Literally just brewed it today and this is the first time using this tank.Does it affect the taste much?

I actually only caught the leak because the blowoff started bubbling with the glycol chiller running. Made me question what was happening so I opened the top and partially pulled the coil out, started the chiller flow and got sprayed with glycol… if you zoom in on the post on the left, you can see the break in the weld.Does it affect the taste much?

Attachments

Why is this even a question? Dump it.

That’s what we’re doing. I read a lot on It last night. No one has had this issue so wasn’t sure what to do. It’s getting dumped today.Why is this even a question? Dump it.

- Joined

- Mar 10, 2021

- Messages

- 2,773

- Reaction score

- 2,394

Propylene glycol is actually used for colonoscopy prep. So maybe save the batch for when you come due for that and drink it all down in the week before!

All kidding aside, I'd probably just dump it because I can't imagine it tasting good or having the correct body.

All kidding aside, I'd probably just dump it because I can't imagine it tasting good or having the correct body.

Yep. Unfortunately that’s whatis going to happen. Not worth it.Propylene glycol is actually used for colonoscopy prep. So maybe save the batch for when you come due for that and drink it all down in the week before!

All kidding aside, I'd probably just dump it because I can't imagine it tasting good or having the correct body.

Oh well. Sucks but at least the brew day on our newly purchased equipment went great! Was able to achieve all numbers and targets on a new system.

I had the exact same issue with my CF5 chiller coil. Luckily I caught it when I was pressure testing everything before my first batch or I would have been dumping mine too.

Take some pictures and email them to Spike, they will send you a free replacement, at least they did for me.

Take some pictures and email them to Spike, they will send you a free replacement, at least they did for me.

I believe propylene glycol is the main ingredient in vape liquid. I used to vape, and when I overdid it, I used to get diarrhea, for what it's worth. I would dump it, no pun intended.

Unfortunately I didn’t buy it directly from Spike so they have no obligation. I bought it from a foreclosed business that stated it was never used. It may not have been used but it must have been handled poorlyI had the exact same issue with my CF5 chiller coil. Luckily I caught it when I was pressure testing everything before my first batch or I would have been dumping mine too.

Take some pictures and email them to Spike, they will send you a free replacement, at least they did for me.

two Things

one- is the beer ok? If it tastes fine then wait a bit (no stomach issues) and decide. That’s a small amount given your overall batch size.

two- do you trust the glycol mix to be fairly sanitary? Closed sealed container? Open to ambient? alot of times the bigger issue is infection. Not sure how fast you go through 40gals but something to think about.

one- is the beer ok? If it tastes fine then wait a bit (no stomach issues) and decide. That’s a small amount given your overall batch size.

two- do you trust the glycol mix to be fairly sanitary? Closed sealed container? Open to ambient? alot of times the bigger issue is infection. Not sure how fast you go through 40gals but something to think about.

That looks like a poor weld to me, it's hollow/cavitated. You can always try to see what Spike has to say.Unfortunately I didn’t buy it directly from Spike so they have no obligation. I bought it from a foreclosed business that stated it was never used. It may not have been used but it must have been handled poorly

But you can have it redone, correctly. Both sides.

I actually only caught the leak because the blowoff started bubbling with the glycol chiller running. Made me question what was happening so I opened the top and partially pulled the coil out, started the chiller flow and got sprayed with glycol… if you zoom in on the post on the left, you can see the break in the weld.

I see it. I'd like to hear what @Bobby_M thinks.

I'd drink it, btw. Nothing makes me sick, and surely not that. I wouldn't serve it to anyone else, though. Hmmm, might take me a while to work through 40g of... what is the beer style?

It’s a brown ale, English/British variationI'd drink it, btw. Nothing makes me sick, and surely not that. I wouldn't serve it to anyone else, though. Hmmm, might take me a while to work through 40g of... what is the beer style?

It’s a brown ale, English/British variation

Yea, that would take a while. I like brown ale, but it's not a session beer for me. I make a hobgloblin clone that I love though (hmm, it's fall, just about that time).

Haha definition of sessionable for me differs from most. I’d call a 7% hazy sessionable haha. This one is pretty light. Comes in around 4.7% and finishes at 1.013. I love this one every time we do it.Yea, that would take a while. I like brown ale, but it's not a session beer for me. I make a hobgloblin clone that I love though (hmm, it's fall, just about that time).

I actually only caught the leak because the blowoff started bubbling with the glycol chiller running. Made me question what was happening so I opened the top and partially pulled the coil out, started the chiller flow and got sprayed with glycol… if you zoom in on the post on the left, you can see the break in the weld.

WTH is this a butt weld? If it is I wouldn't ever buy from that manufacturer again! You would think the tube would penetrate and be welded in place. I would definitely take it back for a refund!I actually only caught the leak because the blowoff started bubbling with the glycol chiller running. Made me question what was happening so I opened the top and partially pulled the coil out, started the chiller flow and got sprayed with glycol… if you zoom in on the post on the left, you can see the break in the weld.

Should have read the feed before reacting but 40 gallons is a bit of work to finish without having a firm idea of the final quality. I would definitely mix the wort with cattle feed or make hog slop out of it.WTH is this a butt weld? If it is I wouldn't ever buy from that manufacturer again! You would think the tube would penetrate and be welded in place. I would definitely take it back for a refund!

Should have read the feed before reacting but 40 gallons is a bit of work to finish without having a firm idea of the final quality. I would definitely mix the wort with cattle feed or make hog slop out of it.

or give to a buddy with a home distillery

That is if you want to put the work into letting it ferment and occupy your equipment.

The more I look at it the more I go with never buying from this manufacturer. That weld is garbage, it undercuts the tubing, obviously, they used no filler rod.I actually only caught the leak because the blowoff started bubbling with the glycol chiller running. Made me question what was happening so I opened the top and partially pulled the coil out, started the chiller flow and got sprayed with glycol… if you zoom in on the post on the left, you can see the break in the weld.

Just because he didn't buy it directly from Spike, they should still stand behind their work and consider a replacement for him. If it's not the original weld, all bets are off and he'll need to get it repaired.Should have read the feed before reacting but 40 gallons is a bit of work to finish without having a firm idea of the final quality. I would definitely mix the wort with cattle feed or make hog slop out of it.

LedZeppelin

Well-Known Member

That looks like a poor weld to me, it's hollow/cavitated. You can always try to see what Spike has to say.

But you can have it redone, correctly. Both sides.

The more I look at it the more I go with never buying from this manufacturer. That weld is garbage, it undercuts the tubing, obviously, they used no filler rod.

It's always funny to see how everyone becomes welding experts. What is a cavitated weld? Lol Also it's obvious this weld didn't use filler wire. You're welding a 1/4" chuck of stainless to tubing that is probably .035" wall thickness. It's called a fusion weld and you can push enough material from the large cap up onto the tubing.

Have you reached out to Spike? Is it possible the customer mistreated the equipment and they broke the weld? You guys are acting like an angry mob with pitchforks, jesus.

It's always funny to see how everyone becomes welding experts. What is a cavitated weld? Lol Also it's obvious this weld didn't use filler wire. You're welding a 1/4" chuck of stainless to tubing that is probably .035" wall thickness. It's called a fusion weld and you can push enough material from the large cap up onto the tubing.

Have you reached out to Spike? Is it possible the customer mistreated the equipment and they broke the weld? You guys are acting like an angry mob with pitchforks, jesus.

Hahah and the same people complaining about the 'garbage weld' and 'trash manufacturer' are out there brewing in the aluminum kettle they've had for 30 years and plastic buckets. Stainless envy.

Haven’t followed up in a bit, sorry everyone.

We did reach out to Spike and they were amazing through the whole process. They refunded us the cost of the new coil after seeing the pictures of the original and instead of making us wait the two week lead time for a new one so we could re-brew the following weekend, they snagged one from another tank and sent it to us next day. We did split the cost of the new coil with them as we didn’t expect them to cover all the costs of it.

Needless to say, we got the new coil last Friday and re-brewed the batch on Saturday. All is good!

We did reach out to Spike and they were amazing through the whole process. They refunded us the cost of the new coil after seeing the pictures of the original and instead of making us wait the two week lead time for a new one so we could re-brew the following weekend, they snagged one from another tank and sent it to us next day. We did split the cost of the new coil with them as we didn’t expect them to cover all the costs of it.

Needless to say, we got the new coil last Friday and re-brewed the batch on Saturday. All is good!

Fusion welding is a generic term, come on, what are you saying? Of course, it was TIG welded and under cut and obviously, their wasn't enough metal left to prevent a break.It's always funny to see how everyone becomes welding experts. What is a cavitated weld? Lol Also it's obvious this weld didn't use filler wire. You're welding a 1/4" chuck of stainless to tubing that is probably .035" wall thickness. It's called a fusion weld and you can push enough material from the large cap up onto the tubing.

Have you reached out to Spike? Is it possible the customer mistreated the equipment and they broke the weld? You guys are acting like an angry mob with pitchforks, jesus.

LedZeppelin

Well-Known Member

Fusion welding is a generic term, come on, what are you saying? Of course, it was TIG welded and under cut and obviously, their wasn't enough metal left to prevent a break.

A fusion weld is pretty specific. It's a TIG weld with no addition of filler wire. I've been in the sanitary stainless steel welding industry for 15 years. A fusion weld is going to be undercut as you're not adding material to create a fillet. It's common and perfectly acceptable for this application.

Sounds like you might need a quick lesson on welding. Jody has an amazing channel and just put out a video on stainless steel welding. I've even timestamped it to the part where he talks about fusion welding for ya

Knowing basically zero about welding, I gotta say the welds on my newer Spike gear are beautiful, and even better than the fine work they did on my custom HLT from their early days. It looks and sounds like the cooling coil welds pose additional challenges. I'm glad (and completely unsurprised) that Ben and the gang stand behind their products.

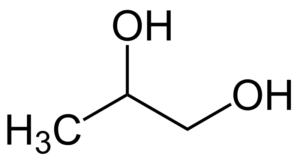

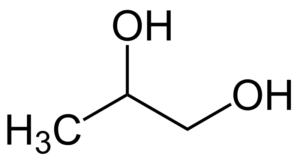

Propylene Glycol

Propylene glycol is a drug that industries widely use in many cosmetics and hygiene products as a food additive or ingredient. In addition, the US and European health officials proclaim it as usually secure for food use.However, as it is also an element in antifreeze, it has become contentious. This had resulted in health issues about the potential toxic impacts of eating products containing it. This paper examines what is propylene glycol, its uses, and whether it is harmful to health or not.

Structure of Propylene Glycol

It is a synthetic food additive belonging to the same category of chemicals as alcohol. It is a mildly syrupy liquid, colourless, odourless, a little thicker than water and has almost no flavour.

Also, it can also dissolve some materials better than water and is also useful for moisture retention. As a food additive, this makes it very beneficial, so it can be discovered in a broad range of processed ingredients and beverages.

Other designations that include is regarded as:

- Methyl ethyl glycol

- 1,2-propanediol

- 1,2-dihydroxy propane

- Trimethyl glycol

Side Effect of Propylene Glycol

Ethylene glycol is extremely toxic to individuals and we do not use it in food products. In addition, the U.S. Food and Drug Administration (FDA) has “usually acknowledged as secure”. Besides, we can use it as an additive for immediate and indirect meals in the US.In Europe, they use it in meat as the colours, emulsifiers, antioxidants, and enzymes, with up to 0.45 grams per pound (1 gram/kg) allowable in the ultimate meat item.

By contrast, one individual who acquired toxicity signs received 213 grams of propylene glycol per day. This is more than 100 times what we find in the median diet for an individual of 120 pounds (60-kg). There is only one recorded instance of food-borne toxicity.

A person who consumes very big quantities of propylene glycol-containing cinnamon whiskey and discovered himself unconscious. Although his symptoms link to alcohol as well, some may ascribe to propylene glycol.

Overall, we don’t find any other instances of adverse or toxic impacts of propylene glycol in ingredients apart from individuals with allergies and one instance of unnecessary consumption.

Since present intakes are predictable to be above the suggested rate. However, it may be important to decrease nutritional sources wherever possible, particularly as the primary sources are extremely processed products.

Propylene Glycol in Food

Common foods include soft drinks, marinades, and dressings, cake mixing, frosting, popcorn, food colouring, quick foods, bread and milk goods.Unfortunately, if we use propylene glycol instead of a direct component as a holder or solvent for another additive, such as taste or colour, it may not be mentioned on the food label.

I've seen huge tanks of propylene glycol at the airport. I believe it's what they spray on airplanes to de-ice them (that's a guess).

A fusion weld is pretty specific. It's a TIG weld with no addition of filler wire. I've been in the sanitary stainless steel welding industry for 15 years. A fusion weld is going to be undercut as you're not adding material to create a fillet. It's common and perfectly acceptable for this application.

Sounds like you might need a quick lesson on welding. Jody has an amazing channel and just put out a video on stainless steel welding. I've even timestamped it to the part where he talks about fusion welding for ya

Thanks for the heads up but you don't have to tell me the sky is blue, right undercut, just like I said. Should it have been? No. The manufacturer recognized that and replaced it with a more robustly welded system and it obviously wasn't the right decision to weld that part without filler rod.

https://www.propylene-glycol.com/industrial-propylene-glycol/aircraft-de-icersI've seen huge tanks of propylene glycol at the airport. I believe it's what they spray on airplanes to de-ice them (that's a guess).

Thanks for the heads up but you don't have to tell me the sky is blue, right undercut, just like I said. Should it have been? No. The manufacturer recognized that and replaced it with a more robustly welded system and it obviously wasn't the right decision to weld that part without filler rod.

We weld these parts with a fusion weld as stated. Been doing it for probably 5 years like that and this is the first broken weld we’ve seen. Who knows what caused the break but we replaced it for the customers.

We weld these parts with a fusion weld as stated. Been doing it for probably 5 years like that and this is the first broken weld we’ve seen. Who knows what caused the break but we replaced it for the customers.

Outstanding that you comment here.

Good on you! I will reconsider my position but welds break for a reason and the use of fusion welding (like its some sort of nuclear reaction weld) as a description muddies the water as a fusion weld can be done with TIG, oxy/acetylene, spot welder, friction, or even a laser. We can be precise and just cal a TIG weld a TIG weld.We weld these parts with a fusion weld as stated. Been doing it for probably 5 years like that and this is the first broken weld we’ve seen. Who knows what caused the break but we replaced it for the customers.

BTW I agree with passes pawn and I commend Spike Brewing for dropping in on this forum and furthermore supporting our member Rob2010SS from Pratt Brewing with a replacement and displaying great customer service where some manufacturers might just blame the brewer for mishandling or differ the seller and pointing the finger.

Similar threads

- Replies

- 22

- Views

- 1K

- Replies

- 2

- Views

- 741