Remove debris and rinse with a hose spray gun. (1-2 minutes)

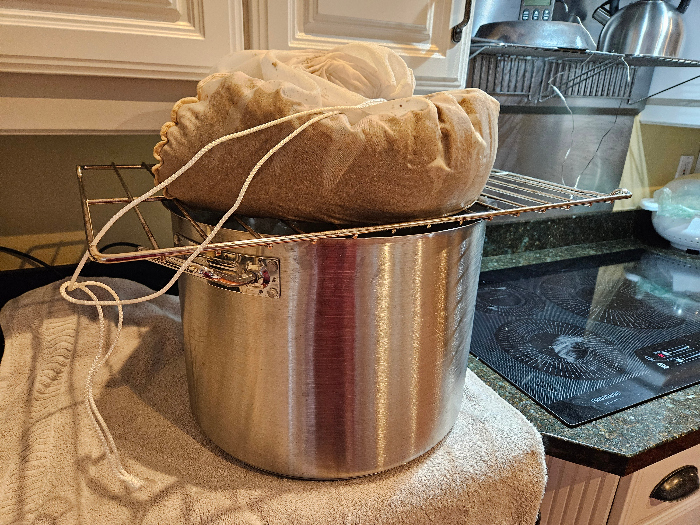

Pour in about 2L hot PBW solution and wash element, centre rod and wall, etc. with a brush and cloth while the pump is running (on low speed). (5ish minutes)

Have a cup of tea. (5 minutes)

Rinse well a few times with hose spray gun and flush pump pipework by running the pump briefly. (3ish minutes total)

Done. Most of the other stuff used during the day, malt pipe, filters, etc. got cleaned after mash out. All that's left is a hose and immersion chiller...

I have to say the whole list looks like more than 15 minutes.

If I were going to use a hose, I'd have to lug the machine out in the yard and bend over to clean it. Maybe it's worth it to reduce the mopping, but probably not, since the malt pipe spills so much sugar solution.

Uneven mash bed temperatures

No recirculation

No mash temperature control

No pre-heat (delay timer)

No pump to move the wort

No step mashing

I don't think the mash temperature varies enough to matter. I don't think constant recirculation matters, since beer comes out fine without it. As for temperature control, I have a stove and a thermometer. Always worked in the past.

I thought I would need a pump, but I used a saucepan, and it took maybe two minutes, so now I would rather not have a pump, even if it were free. When the level in the kettle was low, I picked it up and poured. Didn't have to clean a pump or hoses.

I step-mashed. Just turned the heat back on and stirred. The stove heats the mash very quickly. I actually timed it a while back. It takes 6 minutes to go from 136 to 155. I don't think the Braumeister can beat that.

I don't believe this stuff makes any difference in the product. People win awards with all kinds of equipment. Less work, same product with BIAB. That's how it looks to me, anyway.

If it weren't for the cleaning and parts problems, I'd stick with the Braumeister. It's nice to have everything simplified by technology, and it's fun. If it were easier to clean, I'd stay with it until a part I could not replace broke or disappeared. Speidel's US support is very bad, and little niche companies often have short lives.

I couldn't get a wifi module for it. I don't know if they have restocked yet. Couldn't order an O-ring or a wifi cable. Well, that's not totally true. I found an O-ring at a foreign site for something like $70, so I guess I could pay that and get one in three weeks or so. I forget the actual figure. Speidel kindly sent me a weird proprietary cable from Germany so I was able to fix their faulty firmware. They should have made the unit compatible with ordinary USB cables so people could flash the firmware without a cable they can't buy in the US. The Apple approach is somewhat insulting, and it's a major problem when firmware doesn't work, which happened to everyone who had the firmware I had. If the controller poops out, and Speidel isn't stocking them, I'll have to make one. I don't know how long the original pumps will be available.

It turned out the wifi module, which sells for the startling price of $400, was a bad idea. You can't use it without connecting to Speidel's site, and you have to let them store your recipes. I have a SmartRef that hooks up seamlessly to a phone app, and it will save stuff to my phone. Speidel could have done that, and they could have offered a PC app that worked with a regular cable. What happens if Speidel goes bust? No website. No saved recipes. And how can a wife module cost $400? It kind of reminds me of Festool, if anyone here is familiar with that outfit.

I wonder who is paying $3K for new Braumeisters. I only shelled out $950, including shipping, and in retrospect, it doesn't seem like a very good deal. I would feel awful if I had $3K in it.

I don't discount the fun factor of owning a brewing robot, but I think that varies from person to person.