I have a few dozen 5.5 gal soda kegs that were converted to Sankes. Picked them up from a winery for cheap. I've femented in them before, but it's always been a pain

My goal was to be able to clean out yeast cake and hop debris without pulling the spear, and dry hop in secondary without pulling the spear, and I wanted to share my solution as I've gotten a lot of great help from this site.

First step was to build a keg washer. It has to hold the keg inverted, hook to my HLT to recirc hot PBW, hook to my home water heater to rinse, dried filtered compressed air to dry, and cO2 to sanitize.

The side benefit to this cart was it occurred to me if I combined a counterflow chiller, I could use my hose input for cold city water as opposed to hot, and my hook-up to the HLT for ice water (as oppsosed to hot PBW) to finish the chill as our ground water can be 85F+ in the summer.

I also HIGHLY modified the coupler for the cleaner, increasing both the beer out and gas in ports significantly.

Here's a pic, 90% completed.

https://drive.google.com/open?id=0B4vXJz1SOThZQ1RfZmZ1bHZHOEU

I was also concerned about yeast/hop debris clogging the gas port despite the fact I'm exhasting out the back of the keg, so the washer is designed to introduce 10 PSI of air through the gas out port while rinsing and cleaning.

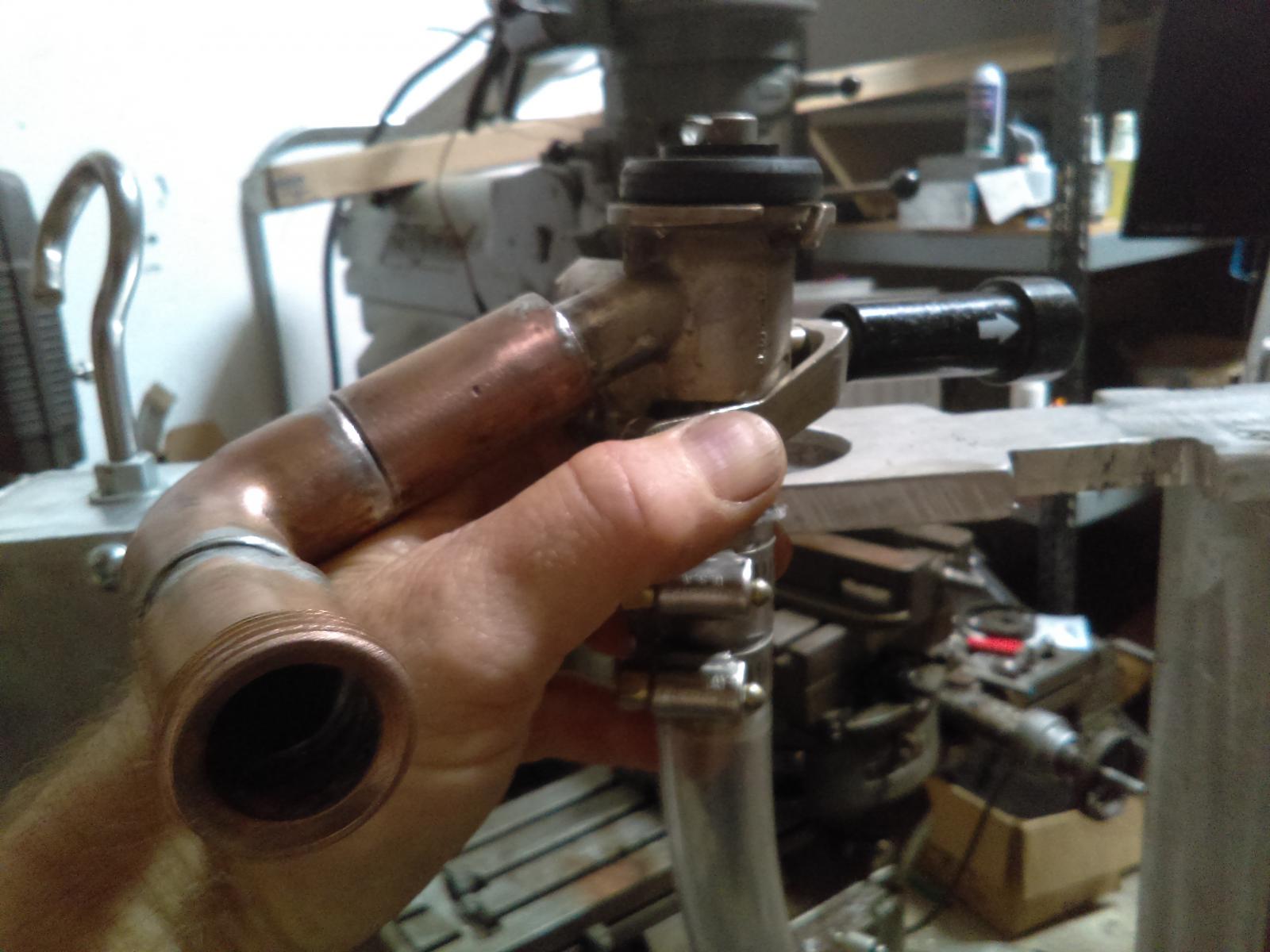

2nd step was to find a way to get large debris out, as the gas port on the coupler is WAY too small. I achieved this by milling out the threads and milling a radius on this fitting:

https://www.brewershardware.com/1_5-Tri-Clover-X-1-NPS-Fitting.html?category_id=287

result:

https://drive.google.com/open?id=0B4vXJz1SOThZNjFOekJTQU5VZGM

These silver soldered on the keg with no problems.

I also wanted a sanitary thermowell in these kegs, and with a 1-.5" Tri-Clover blank with a hole drilled in I was able to silver solder a threaded thermowell into the cap. (to keep threrads out of the ferm)

I've tested them to 50 psi overnight, but I'm just using them for fermentors, so they won't hold pressure. The only other mod I had to do was cut the spears, a bit shorter than standard for the secondary kegs and a bit shorter than that for primary.

Haven't tried them yet, but will in the next few weeks. Here's the keg:

https://drive.google.com/open?id=0B4vXJz1SOThZME5oU1VZejNKdWc

I welcome comments / advise...

My goal was to be able to clean out yeast cake and hop debris without pulling the spear, and dry hop in secondary without pulling the spear, and I wanted to share my solution as I've gotten a lot of great help from this site.

First step was to build a keg washer. It has to hold the keg inverted, hook to my HLT to recirc hot PBW, hook to my home water heater to rinse, dried filtered compressed air to dry, and cO2 to sanitize.

The side benefit to this cart was it occurred to me if I combined a counterflow chiller, I could use my hose input for cold city water as opposed to hot, and my hook-up to the HLT for ice water (as oppsosed to hot PBW) to finish the chill as our ground water can be 85F+ in the summer.

I also HIGHLY modified the coupler for the cleaner, increasing both the beer out and gas in ports significantly.

Here's a pic, 90% completed.

https://drive.google.com/open?id=0B4vXJz1SOThZQ1RfZmZ1bHZHOEU

I was also concerned about yeast/hop debris clogging the gas port despite the fact I'm exhasting out the back of the keg, so the washer is designed to introduce 10 PSI of air through the gas out port while rinsing and cleaning.

2nd step was to find a way to get large debris out, as the gas port on the coupler is WAY too small. I achieved this by milling out the threads and milling a radius on this fitting:

https://www.brewershardware.com/1_5-Tri-Clover-X-1-NPS-Fitting.html?category_id=287

result:

https://drive.google.com/open?id=0B4vXJz1SOThZNjFOekJTQU5VZGM

These silver soldered on the keg with no problems.

I also wanted a sanitary thermowell in these kegs, and with a 1-.5" Tri-Clover blank with a hole drilled in I was able to silver solder a threaded thermowell into the cap. (to keep threrads out of the ferm)

I've tested them to 50 psi overnight, but I'm just using them for fermentors, so they won't hold pressure. The only other mod I had to do was cut the spears, a bit shorter than standard for the secondary kegs and a bit shorter than that for primary.

Haven't tried them yet, but will in the next few weeks. Here's the keg:

https://drive.google.com/open?id=0B4vXJz1SOThZME5oU1VZejNKdWc

I welcome comments / advise...