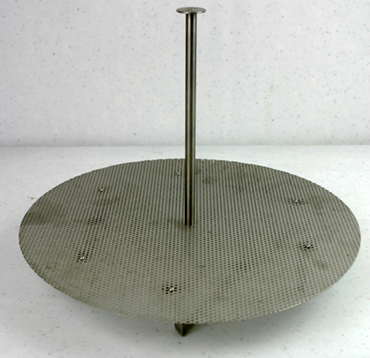

I'm using a 12" morebeer false bottom in a 10 gallon igloo cooler. This weekend I got stuck sparges twice while using this false bottom.

I was using a pretty fine crush and a 16lb grain bill (all 2-row), but the last few similar batches I had no problems using the same mill. I'm using pretty reinforced 3/8" silicone tubing that I don't think was collapsing so I don't think that was the problem.

Had 2 questions

1) Would the jaybird false bottom provide a significant improvement over this one? Is there a "best" false bottom out there, or is mine about as good as it gets?

2) I couldnt get my chugger pump to pump really slowly. I would turn it on with the pump output ball valve shut, and then very slowly open it. Even though I was turning the ball valve very slowly, the pump would always go from no flow to slightly too fast (around .5 - 1L/min) and if I slowed it down it would lose prime and stop.

Is this normal?

I used a tan pump previously (now broken) and never had a stuck sparge, so I'm wondering if something about the chugger is a contributing factor.

I was using a pretty fine crush and a 16lb grain bill (all 2-row), but the last few similar batches I had no problems using the same mill. I'm using pretty reinforced 3/8" silicone tubing that I don't think was collapsing so I don't think that was the problem.

Had 2 questions

1) Would the jaybird false bottom provide a significant improvement over this one? Is there a "best" false bottom out there, or is mine about as good as it gets?

2) I couldnt get my chugger pump to pump really slowly. I would turn it on with the pump output ball valve shut, and then very slowly open it. Even though I was turning the ball valve very slowly, the pump would always go from no flow to slightly too fast (around .5 - 1L/min) and if I slowed it down it would lose prime and stop.

Is this normal?

I used a tan pump previously (now broken) and never had a stuck sparge, so I'm wondering if something about the chugger is a contributing factor.