xgarland77x

Well-Known Member

- Joined

- Sep 6, 2011

- Messages

- 46

- Reaction score

- 0

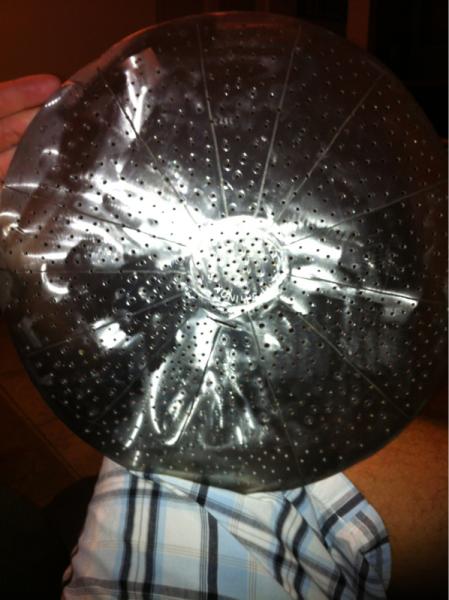

I cut the bottom off a sanke keg and am using a triclover to attach plumbing to the top which has now become my bottom(see first pic).

I want to use the bottom I cut off as a false bottom. I have seen the few threads on here but am wondering if anyone has some advice as to how big the holes should be and how far apart they need to be....

Thanks

I want to use the bottom I cut off as a false bottom. I have seen the few threads on here but am wondering if anyone has some advice as to how big the holes should be and how far apart they need to be....

Thanks