coffearobusta42

Member

My wife's parents just brought down her old college mini fridge - a Sanyo Eclipse Counter-High Refrigerator SR 3770S. It's pretty cool looking with a stainless steel front and all black interior. This particular fridge was clean and still worked. It's quiet and gets very cold.

After removing all the shelves and evaporator drip tray, I still couldn't fit a carboy in there because of all the door hardware. Luckly, it's all one plastic panel thats screwed onto the door. The screws are under the door seal. I used the same screws to reattach the door seal after removing the door panel.

My plastic bucket will fit with about 3/4 inch clearence from the evaporator tray, but is too wide to sit on the bottom of the fridge. While my carboy is just fine on the bottom. Still, they both fit!

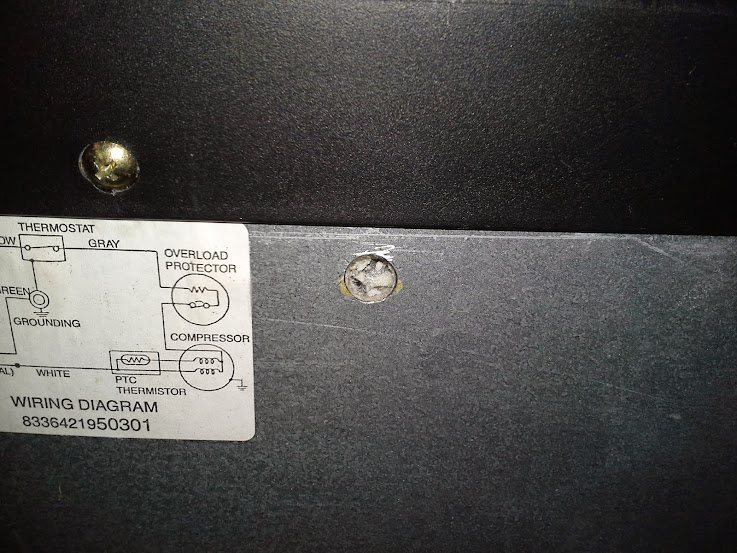

Now I am waiting on delivery of an STC-1000 and am formulating plans on moding my fridge. Anybody have tips on how to locate cooling lines? I can feel around the case while it's running and defintely feel spots that are warmer than others.

All I have is a 18 volt cordless drill...will that be able to drill through the wall?

After removing all the shelves and evaporator drip tray, I still couldn't fit a carboy in there because of all the door hardware. Luckly, it's all one plastic panel thats screwed onto the door. The screws are under the door seal. I used the same screws to reattach the door seal after removing the door panel.

My plastic bucket will fit with about 3/4 inch clearence from the evaporator tray, but is too wide to sit on the bottom of the fridge. While my carboy is just fine on the bottom. Still, they both fit!

Now I am waiting on delivery of an STC-1000 and am formulating plans on moding my fridge. Anybody have tips on how to locate cooling lines? I can feel around the case while it's running and defintely feel spots that are warmer than others.

All I have is a 18 volt cordless drill...will that be able to drill through the wall?