PleasantValleyHops

Well-Known Member

So i should prob start off the way most of these start off telling everyone thanks for inspiration and the experience of the ebrewing to really jump start finally moving to a more controlable setup. also a big thanks to the wife for not killing me for rearranging our basement several times now, and as long as i get our house projects done also i can continue to biuld! Now for the Plans

its going to be a Three vessel single teir set up in my basement.

5500 w elements in both hltherms and boil kettle.

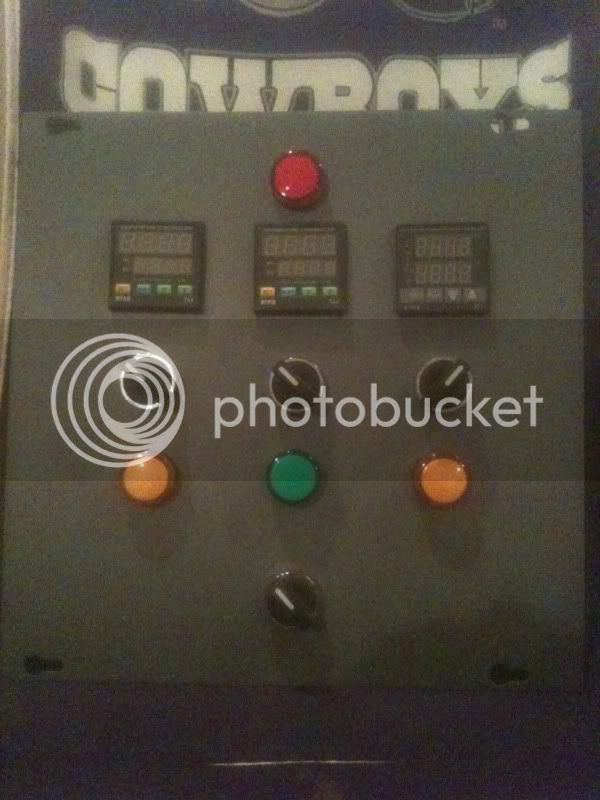

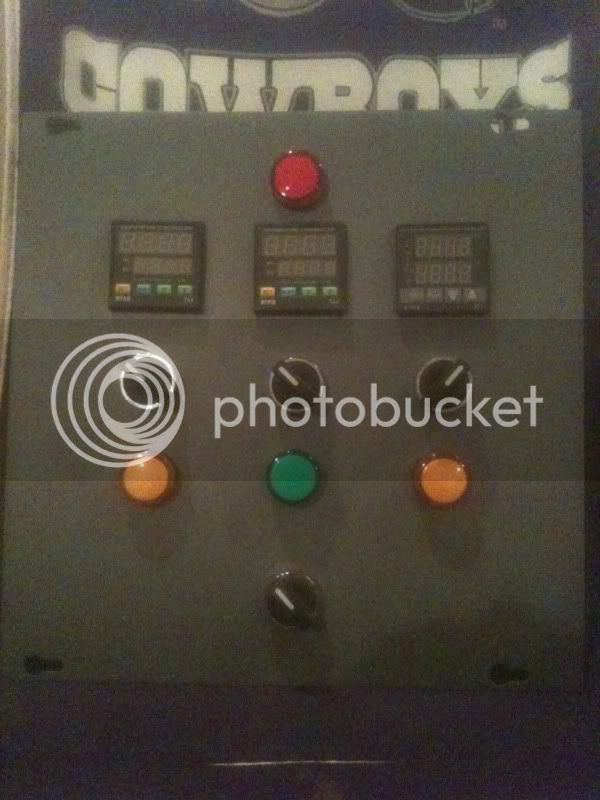

going to be controled by a 3 Pid CP w one pump for wort transfers and such.

ive actually been planning for a little bit but didnt want to make a thread about the biuld until i knew i was a little closer to being able to actually complete things so most parts are actually already here and ready for install. got lucky with some major wiring bonuses such as my subpanel, all wire for the setup. my element recept. and enclosure. this has def. help speed up the process since everything does add up quick.

i will also biuld a hood to help with ventilation so just add it to the list.. here are few pictures to get this whole thing started.. sorry pictures suck. still rockin my old school 3GS iphone!

Sink had to get cut for more space.. sucked cutting 2ft off that beauty but had to do what i had to do!

brew area Hood future

control panel

Overall i know its not going to be the coolest or all fancy.. i like brewing and if it means i need to skip some cosmetics i will. more pictures to come as progress is made.

its going to be a Three vessel single teir set up in my basement.

5500 w elements in both hltherms and boil kettle.

going to be controled by a 3 Pid CP w one pump for wort transfers and such.

ive actually been planning for a little bit but didnt want to make a thread about the biuld until i knew i was a little closer to being able to actually complete things so most parts are actually already here and ready for install. got lucky with some major wiring bonuses such as my subpanel, all wire for the setup. my element recept. and enclosure. this has def. help speed up the process since everything does add up quick.

i will also biuld a hood to help with ventilation so just add it to the list.. here are few pictures to get this whole thing started.. sorry pictures suck. still rockin my old school 3GS iphone!

Sink had to get cut for more space.. sucked cutting 2ft off that beauty but had to do what i had to do!

brew area Hood future

control panel

Overall i know its not going to be the coolest or all fancy.. i like brewing and if it means i need to skip some cosmetics i will. more pictures to come as progress is made.

It is hard to say that to a cowgirls fan though....

It is hard to say that to a cowgirls fan though....