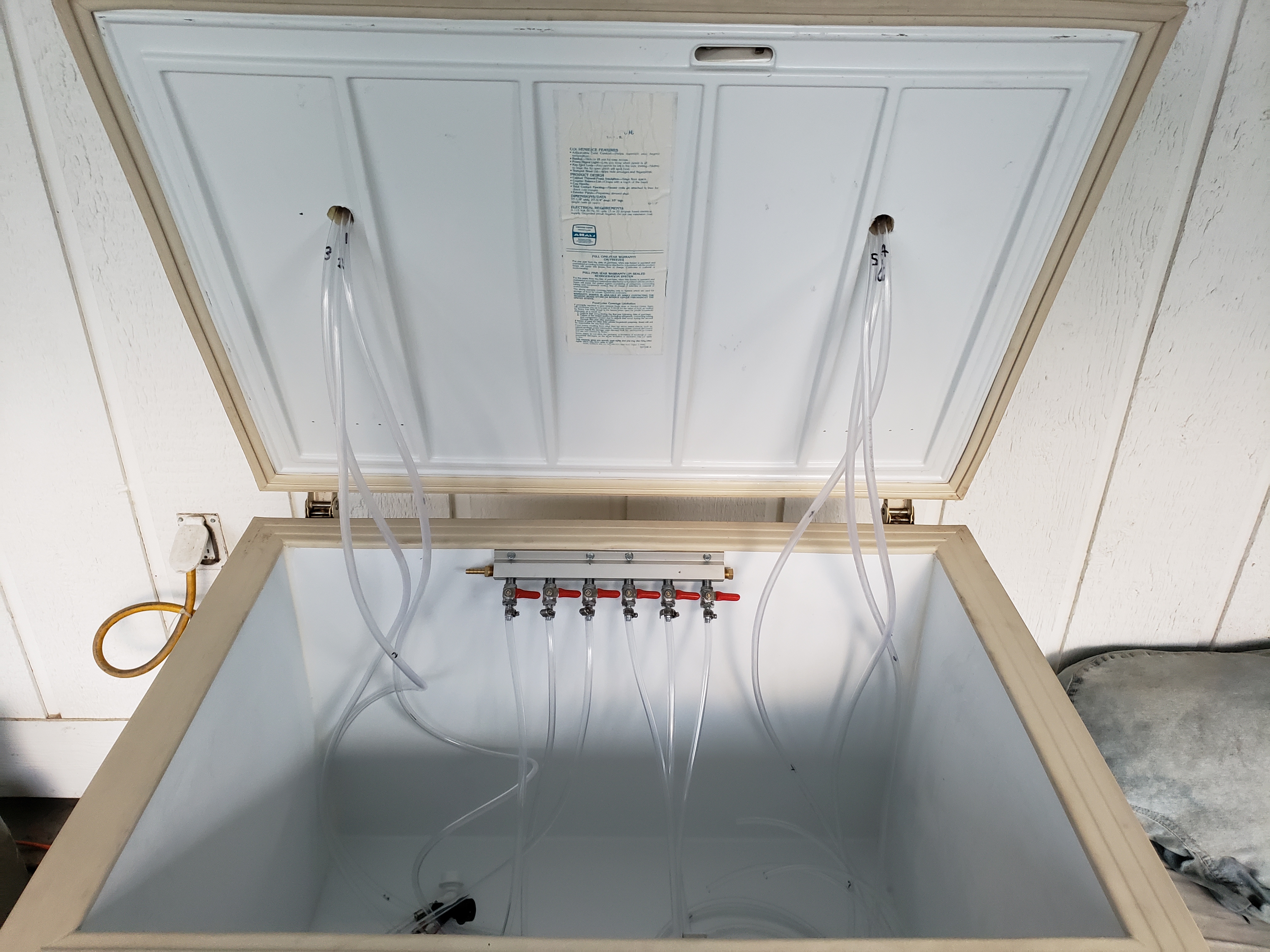

I found a freezer that (according to measurements and someone else's conversion) will fit 6 ball lock corny kegs with some room left over. I'm not doing a collar (putting draft tower on top of door) and I want to put 4 CO2 lines in from outside. That means I'll have to drill about a 2" hole somewhere. Preferably in the side or back of the freezer. Where do the coolant lines etc usually run on a freezer?

This Hotpoint 9.4 is the one I'm thinking right now:

https://www.homedepot.com/p/Hotpoin...rost-Chest-Freezer-HCM9DMWW/305143881#overlay

This Hotpoint 9.4 is the one I'm thinking right now:

https://www.homedepot.com/p/Hotpoin...rost-Chest-Freezer-HCM9DMWW/305143881#overlay