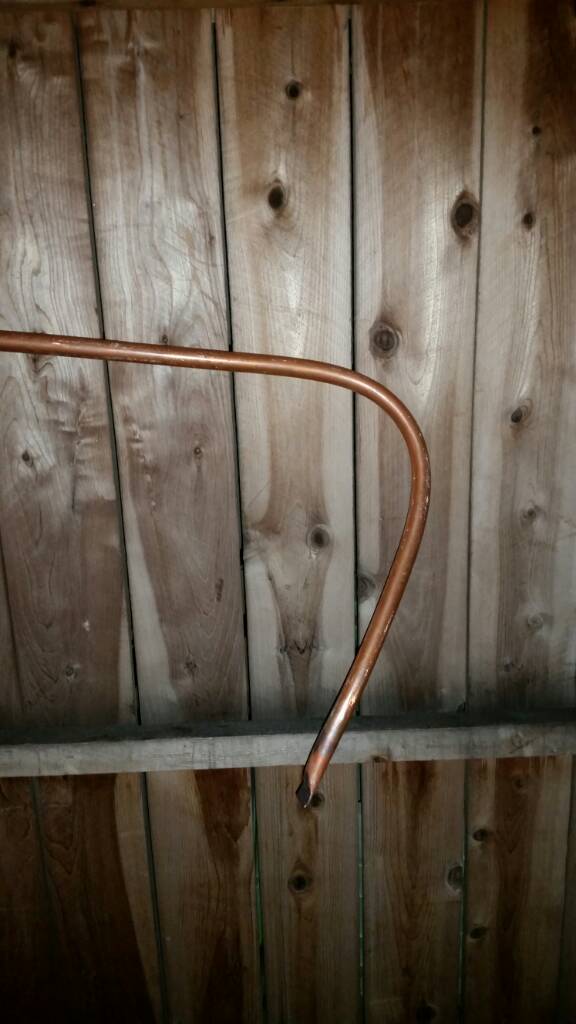

I've bent up a counterflow chiller. All in O.D. sizes, 1/2 and 7/8 soft refrigeration copper. Rolled both straight, close to impossible. 15' mark.

Spinning the 7/8 to make the 1/2 fit about 6 feet. Anchored the 7/8 against the shelf, while parlty spinning the 7/8 to fit the 1/2 all the way.

Closed up the ends and pressurized with nitrogen to 450 PSI.

All I could bend by myself.

Whish I used more length on the straight pre bend, hard to hold while bending. Used a Nitrogen tank to roll around. My wife held the length up as I preloaded the copper. She lowered the length as I bent around the tank. Rolled up nice with lots of work. I let the nitro out, it unsprung a ton.

Not sure where the water connections will land. Will figure that out later and sweat with lead free. A few kinks.

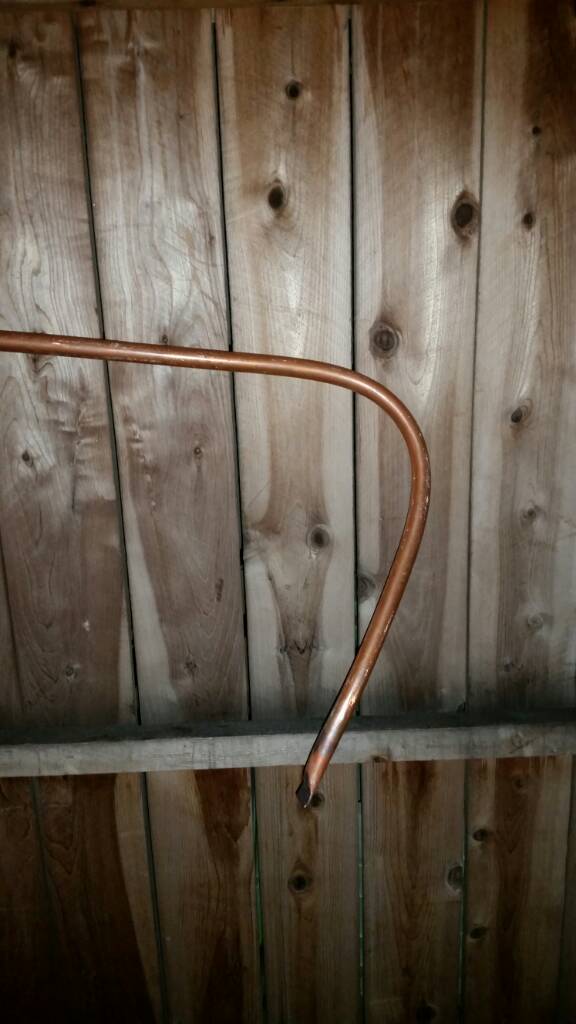

Spinning the 7/8 to make the 1/2 fit about 6 feet. Anchored the 7/8 against the shelf, while parlty spinning the 7/8 to fit the 1/2 all the way.

Closed up the ends and pressurized with nitrogen to 450 PSI.

All I could bend by myself.

Whish I used more length on the straight pre bend, hard to hold while bending. Used a Nitrogen tank to roll around. My wife held the length up as I preloaded the copper. She lowered the length as I bent around the tank. Rolled up nice with lots of work. I let the nitro out, it unsprung a ton.

Not sure where the water connections will land. Will figure that out later and sweat with lead free. A few kinks.