brandonlovesbeer

BrandonLovesBeer

I’ve been wanting to do BIAB more and more but I could never find the size bag for my cooler.

My Brewpot has no insulation so I am not even considering that.

I inquired with Brülosophy about where they purchase their BIAB bags.

If anyone is interested.

https://www.brewinabag.com/?aff=3

But I could not justify paying $60 for my 25gal Rectangular cooler. I thought, “I’m handy and a Jack of all Trades. I’ll just sew one myself.”

So I began doing research and discovered that the shear fabric these bags are made out of is called Polyester Voile.

It’s the exact same material that many shear curtains are made out of.

I went to all the fabric stores and Hobby Lobby to find this material by the yard.

After finding that the price per yard was avg about $5, I took the advice of some other people and began looking in the curtain section.

With my 2gal BIAB in hand to compare fabrics, I went to the curtain section.

Immediately I found what I was looking for.

A 96”x48” shear curtain for $7.

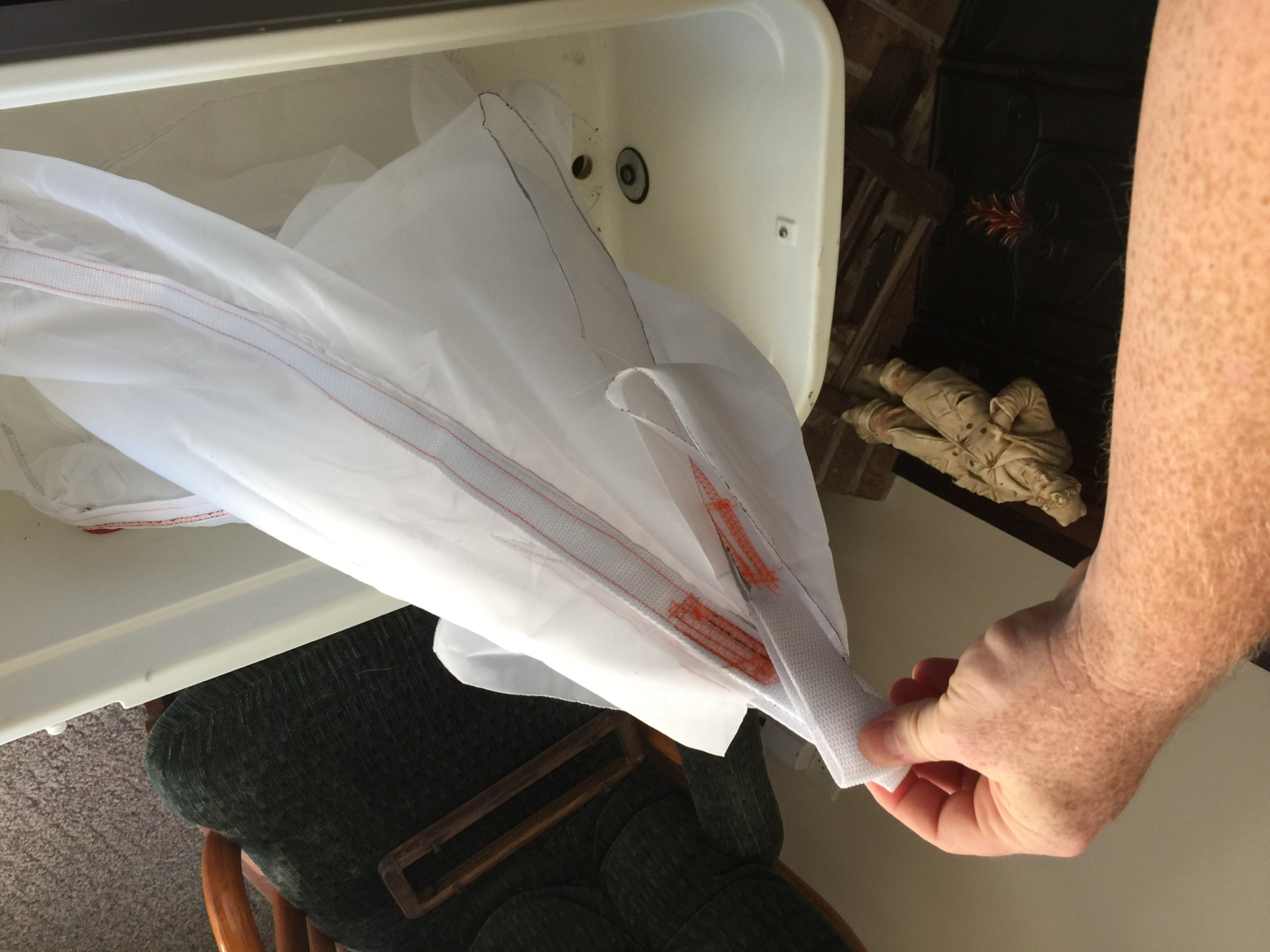

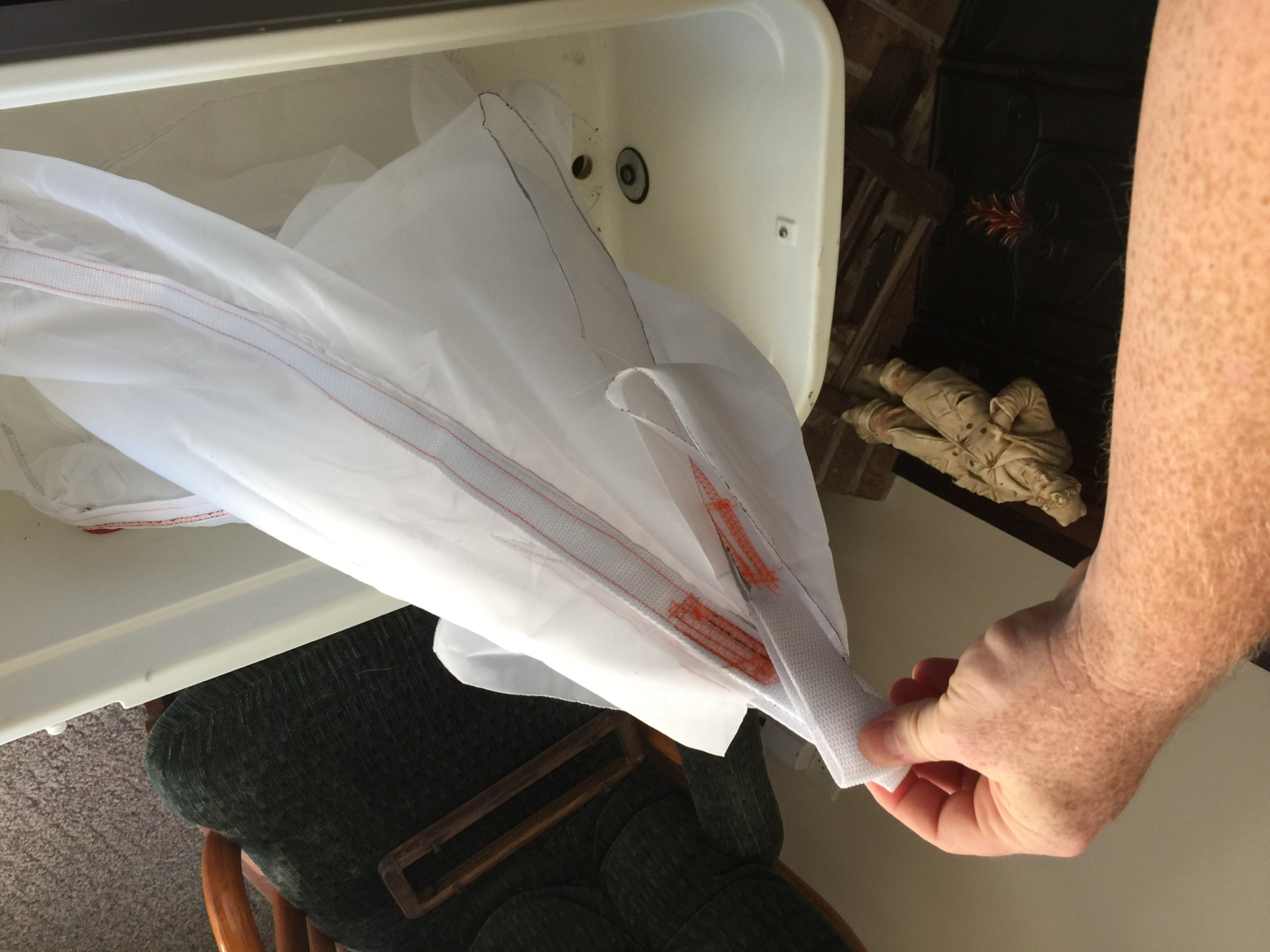

Then I found the fabric to make the support handles as well as polyester thread. And home I went and pulled out the sewing machine and got to work.

The stitches are not pretty and lined up like the pros. But it is completely functional.

Plus I have enough fabric left over to do a could other projects.

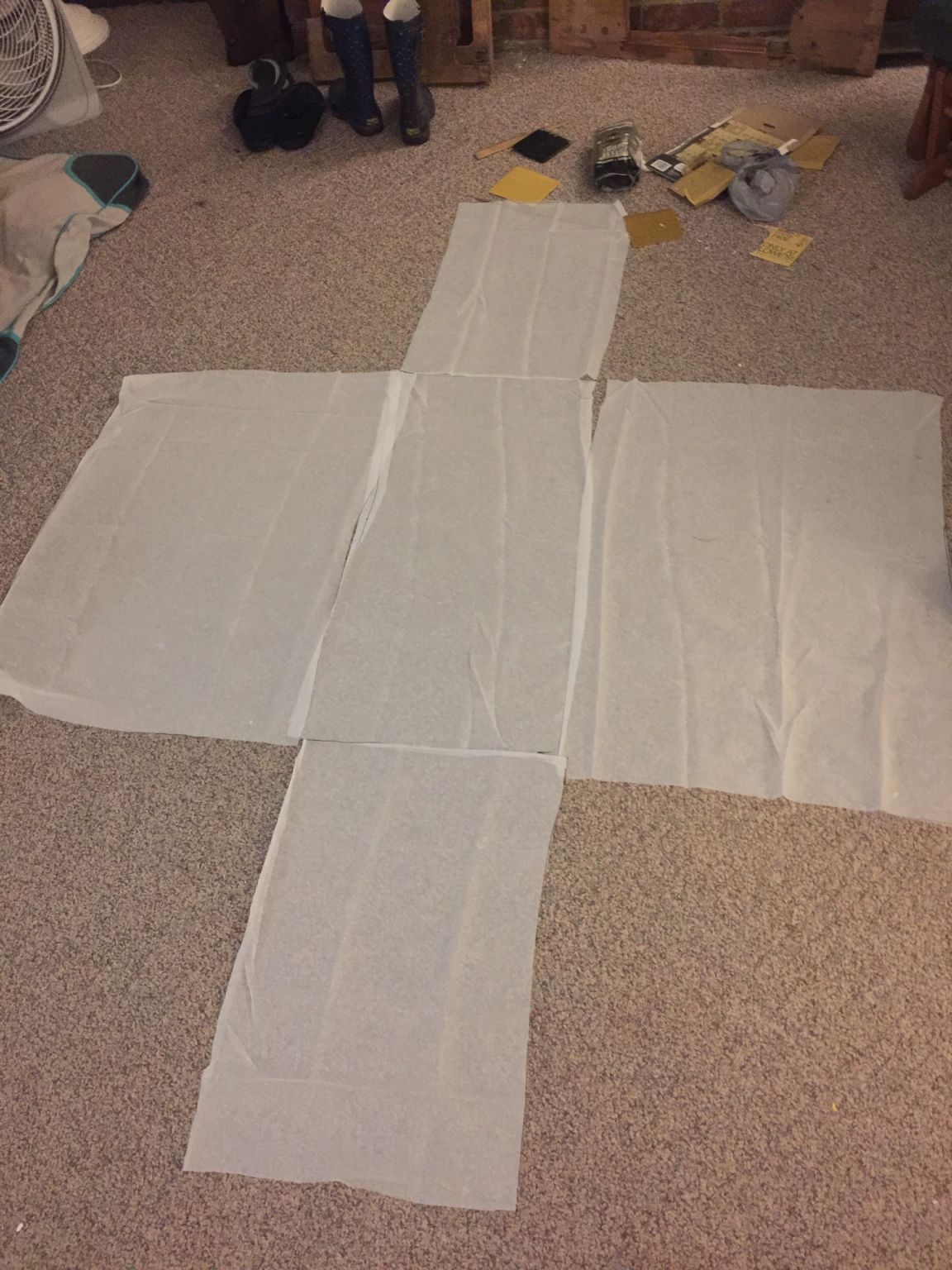

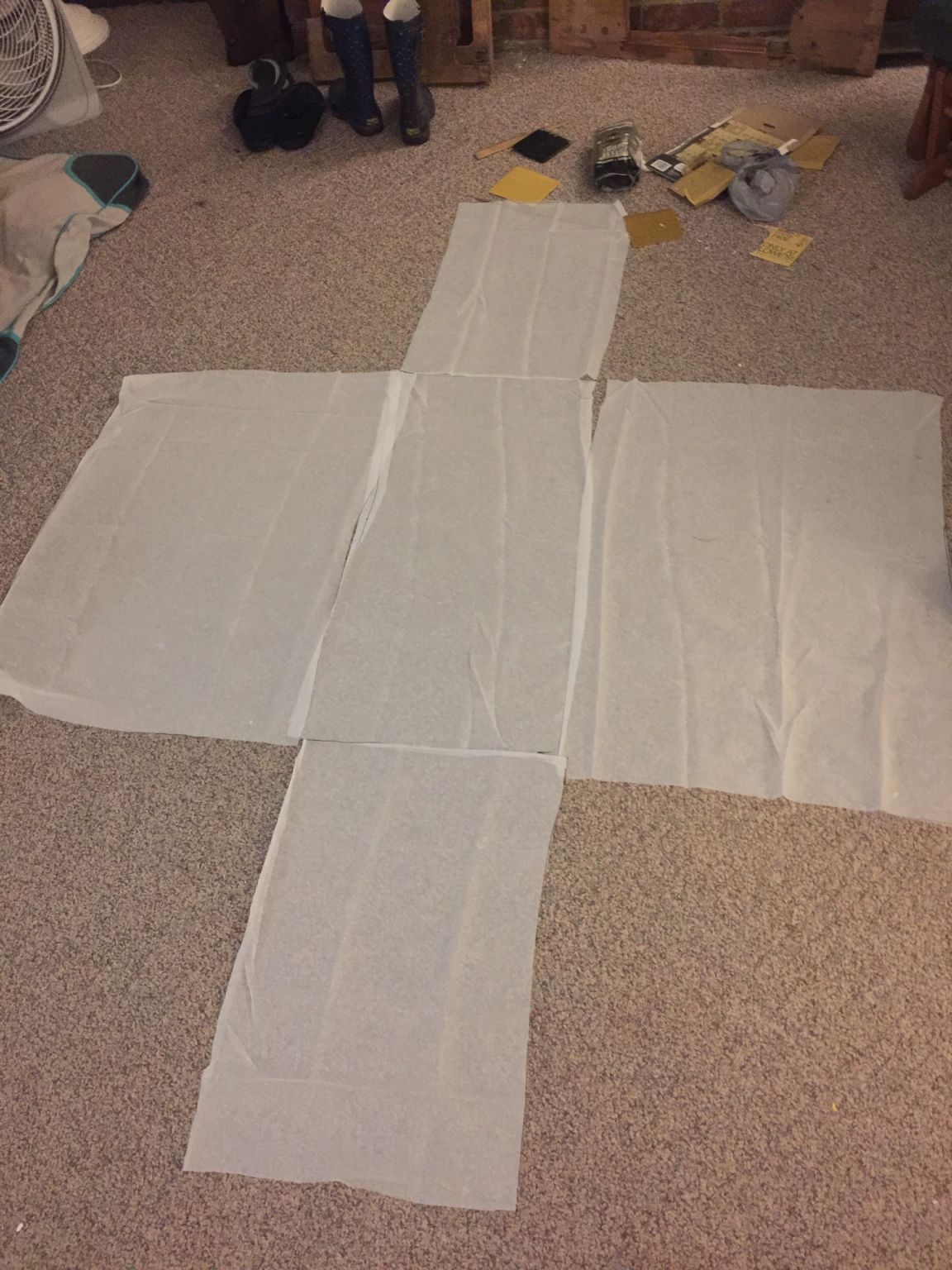

I’ve posted some pictures to show the results of my labor.

Total cost:

$7.00 - Curtain

$8.00 - handle fabric (6yds)

$2.00 - Thread

Total = $17

My Brewpot has no insulation so I am not even considering that.

I inquired with Brülosophy about where they purchase their BIAB bags.

If anyone is interested.

https://www.brewinabag.com/?aff=3

But I could not justify paying $60 for my 25gal Rectangular cooler. I thought, “I’m handy and a Jack of all Trades. I’ll just sew one myself.”

So I began doing research and discovered that the shear fabric these bags are made out of is called Polyester Voile.

It’s the exact same material that many shear curtains are made out of.

I went to all the fabric stores and Hobby Lobby to find this material by the yard.

After finding that the price per yard was avg about $5, I took the advice of some other people and began looking in the curtain section.

With my 2gal BIAB in hand to compare fabrics, I went to the curtain section.

Immediately I found what I was looking for.

A 96”x48” shear curtain for $7.

Then I found the fabric to make the support handles as well as polyester thread. And home I went and pulled out the sewing machine and got to work.

The stitches are not pretty and lined up like the pros. But it is completely functional.

Plus I have enough fabric left over to do a could other projects.

I’ve posted some pictures to show the results of my labor.

Total cost:

$7.00 - Curtain

$8.00 - handle fabric (6yds)

$2.00 - Thread

Total = $17

Last edited: