Nope... a one mile diameter inlet has a lot more weight. The pump doesn't provide suction at all. You need the weight of the liquid in the inlet tubing to push the air out of the pump head.

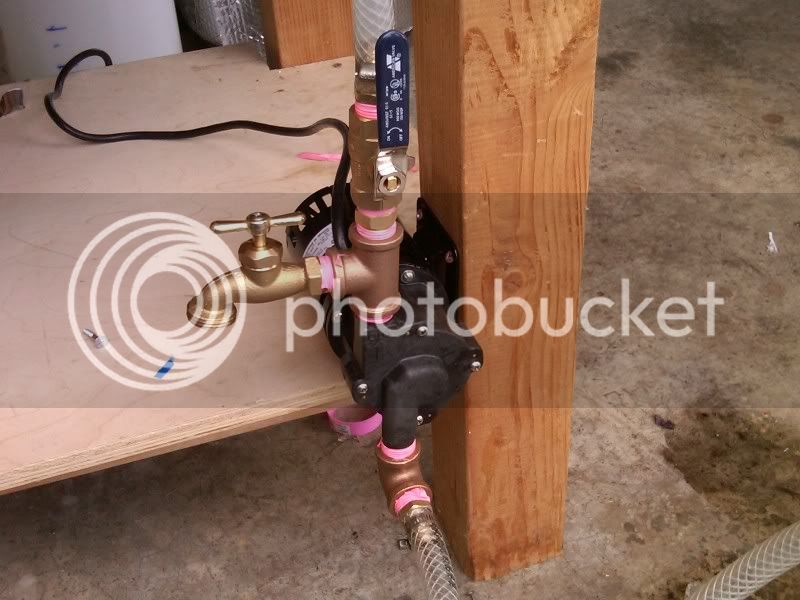

To the point of the siphon tube filling with air/steam and then flushing into the pump's inlet line.... I just ordered a brass schrader valve stem from Mcmaster and I'm going to drill into the elbow of my brass QD and solder that sucker in. A little tap on the valve should let the air escape from the line.

To the point of the siphon tube filling with air/steam and then flushing into the pump's inlet line.... I just ordered a brass schrader valve stem from Mcmaster and I'm going to drill into the elbow of my brass QD and solder that sucker in. A little tap on the valve should let the air escape from the line.