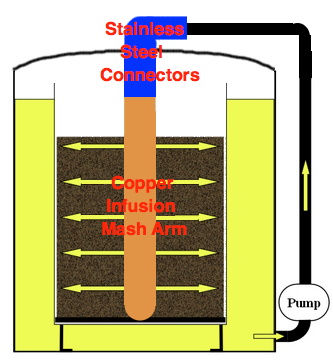

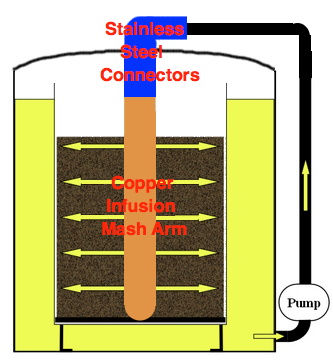

I'm planning to build a continuous infusion mash arm for a eBIAB system as pictured below. Planning to use a Male NPT threaded steel cam lock to a Female NPT copper fitting.

Should I be worried about galvanic corrosion where the copper connects to the steel? If so, what can I do to prevent it?

Should I be worried about galvanic corrosion where the copper connects to the steel? If so, what can I do to prevent it?