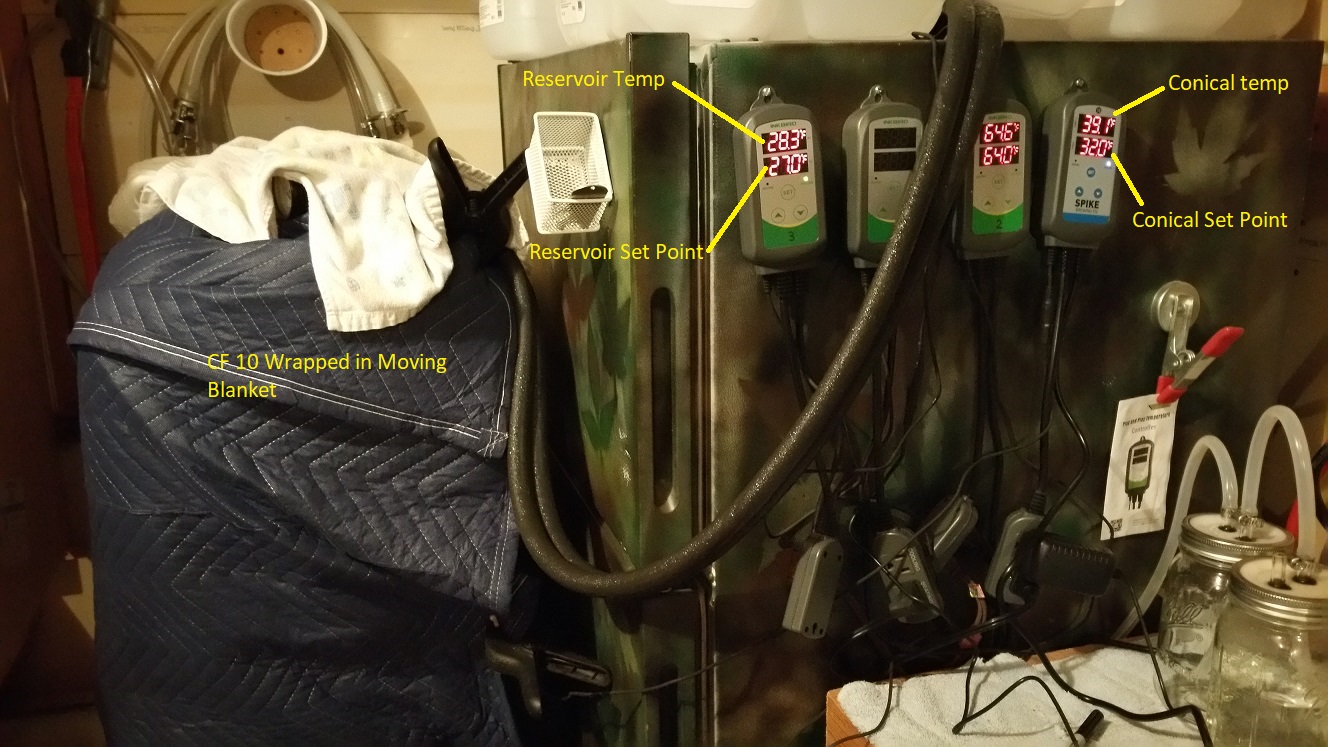

See attached pic.

I have a 33% Glycol-67% Water mixture in a reservoir in my ferm chamber refrigerator. The system does well at moving temps down to the low 40s, but now, I can't complete a crash to 32 degrees.

Since last night, when the temp was 39.1, the temp this morning was 38.7. It simply isn't cooling, and I don't know why.

Five Gallon Batch (maybe 6 gallons in the fermenter).

Ambient in the garage: 64 degrees.

Conical wrapped in moving blanket down to floor.

Two towels on top cover the portion I can't reach w/ the moving blanket.

Condensation on both supply and return lines; they're cold.

Tilt Hydrometer in Conical confirms temp read on temp control.

Morrey does something similar with his SSBrewtech unitanks. He feeds his with a Penguin chiller which is much more responsive to temp than mine, but he keeps his at 28 degrees.

Mine is one degree lower--and the reservoir temp is more than low enough to take this down to 32 degrees.

Why? Is it possible I'm forming ice on the coils and that's limiting cooling? @Morrey suggested raising the temp of the coolant to 30 degrees. The only other thing I can think is that there's so much heat gain into the fermenter that it's offsetting the cooling. If so, how do any of the rest of you manage this?

To reiterate: it's not the temp of the reservoir. It's plenty cold, and recovers well.

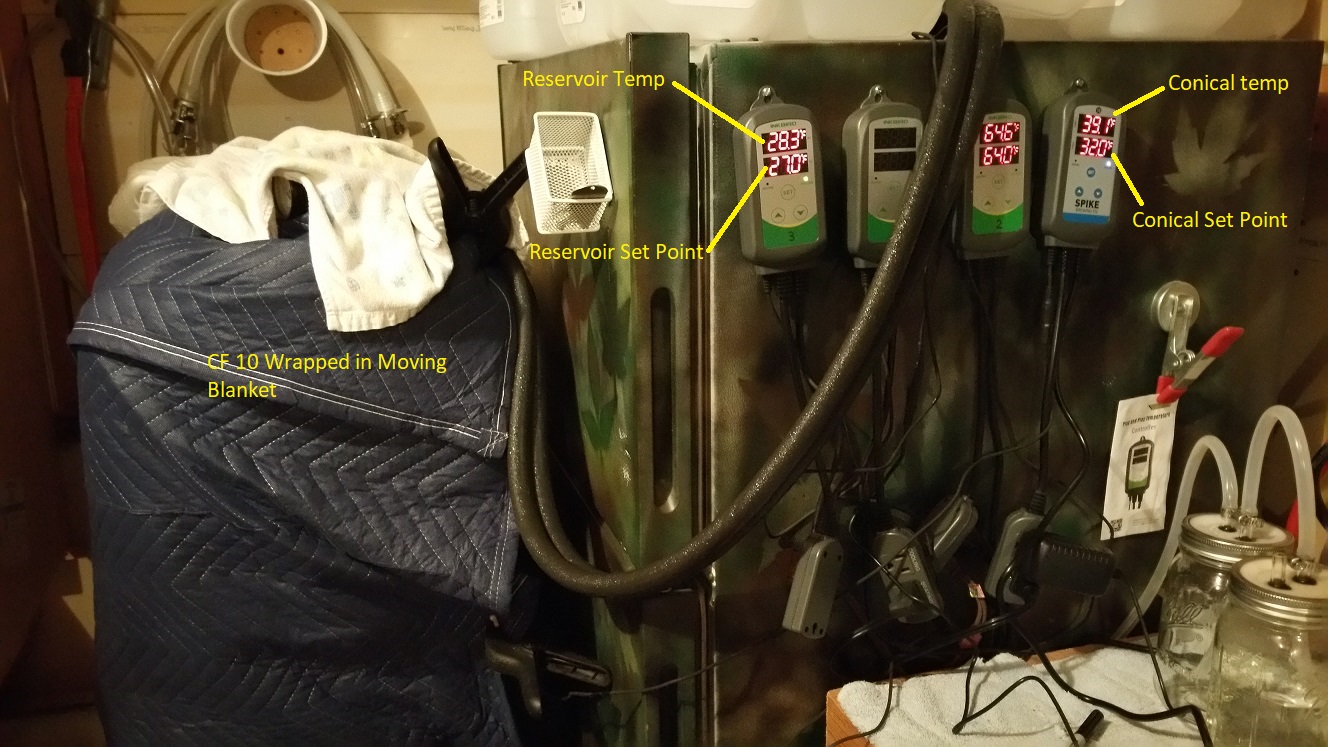

I have a 33% Glycol-67% Water mixture in a reservoir in my ferm chamber refrigerator. The system does well at moving temps down to the low 40s, but now, I can't complete a crash to 32 degrees.

Since last night, when the temp was 39.1, the temp this morning was 38.7. It simply isn't cooling, and I don't know why.

Five Gallon Batch (maybe 6 gallons in the fermenter).

Ambient in the garage: 64 degrees.

Conical wrapped in moving blanket down to floor.

Two towels on top cover the portion I can't reach w/ the moving blanket.

Condensation on both supply and return lines; they're cold.

Tilt Hydrometer in Conical confirms temp read on temp control.

Morrey does something similar with his SSBrewtech unitanks. He feeds his with a Penguin chiller which is much more responsive to temp than mine, but he keeps his at 28 degrees.

Mine is one degree lower--and the reservoir temp is more than low enough to take this down to 32 degrees.

Why? Is it possible I'm forming ice on the coils and that's limiting cooling? @Morrey suggested raising the temp of the coolant to 30 degrees. The only other thing I can think is that there's so much heat gain into the fermenter that it's offsetting the cooling. If so, how do any of the rest of you manage this?

To reiterate: it's not the temp of the reservoir. It's plenty cold, and recovers well.