ZmannR2

Well-Known Member

So I want a 10gal kettle with a BoilCoil and controller for mashing BIAB and boiling. Here's what I'm thinking:

Bayou Classic 1440 10 gal $76 plus false Bottom from Bobby I think like $29 (btw will the false bottom work over the boilcoil?)

120V BoilCoil or should I do the 240V?? (roughly $140-150)

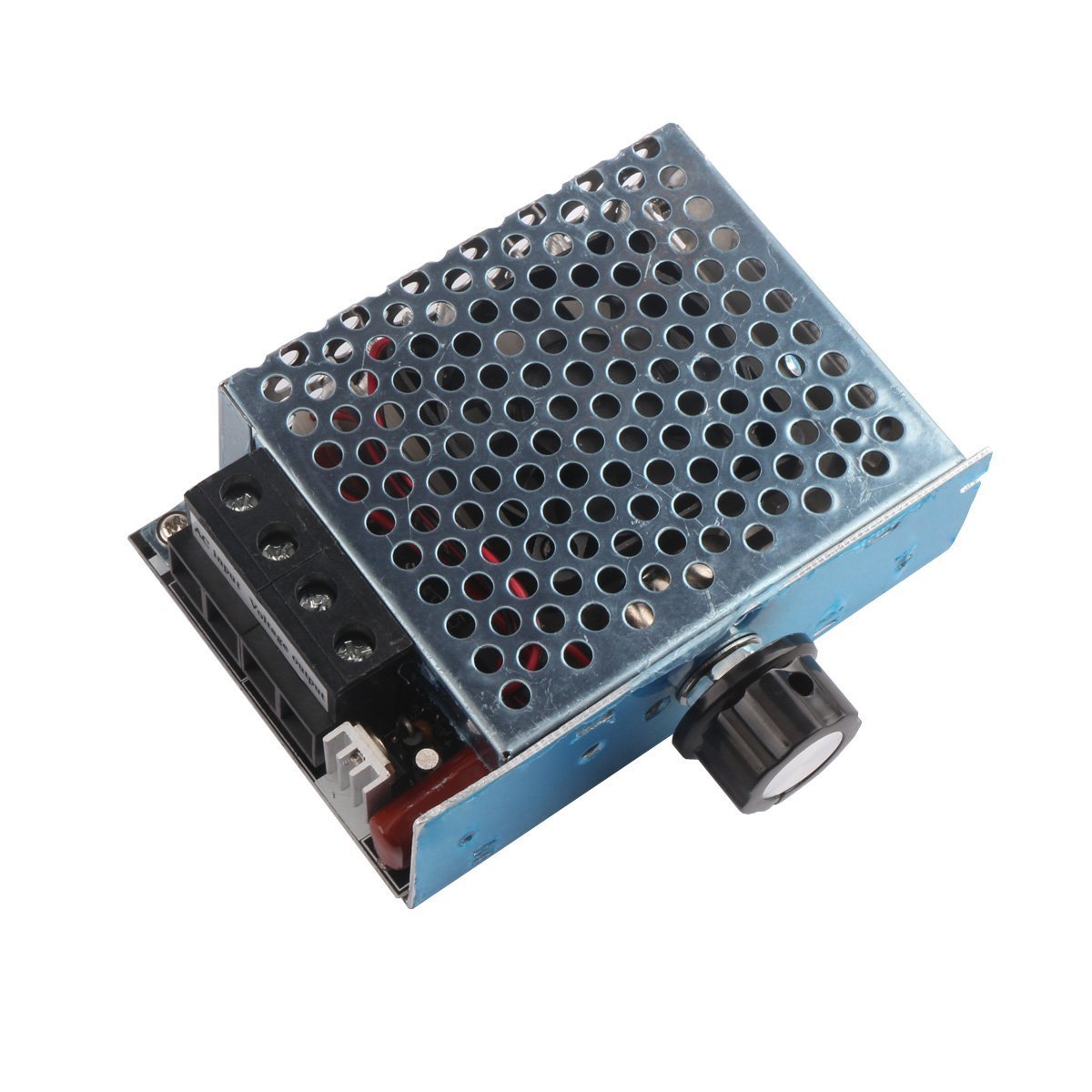

And what is a cheap good temp controller for the BoilCoil??

So with those things bought, would that work??

Thanks for the help!

Bayou Classic 1440 10 gal $76 plus false Bottom from Bobby I think like $29 (btw will the false bottom work over the boilcoil?)

120V BoilCoil or should I do the 240V?? (roughly $140-150)

And what is a cheap good temp controller for the BoilCoil??

So with those things bought, would that work??

Thanks for the help!

Last edited by a moderator: