A while back, I posted a thread in the Equipment/Sanitation forum regarding modification of an off-the-shelf peristaltic pump so it could be used for homebrewing. The original thread is here.

Several months later, I finally got off my lazy bum and tried to make this idea a reality.

For those that just want the quick and dirty, it's a self-priming peristaltic pump that can be hand driven, or modded to run with an electric drill. It also can be used to start a siphon, and then open up to let the siphon run. I haven't done serious tests yet, but 1.5 to 2 Gal/min (6 to 8 L/min for those across the pond) seems like it's capacity. I'm not sure how high it can pump vertically (it's head) but it should be adequate for most homebrewing purposes.

Teardown and build Pictures!

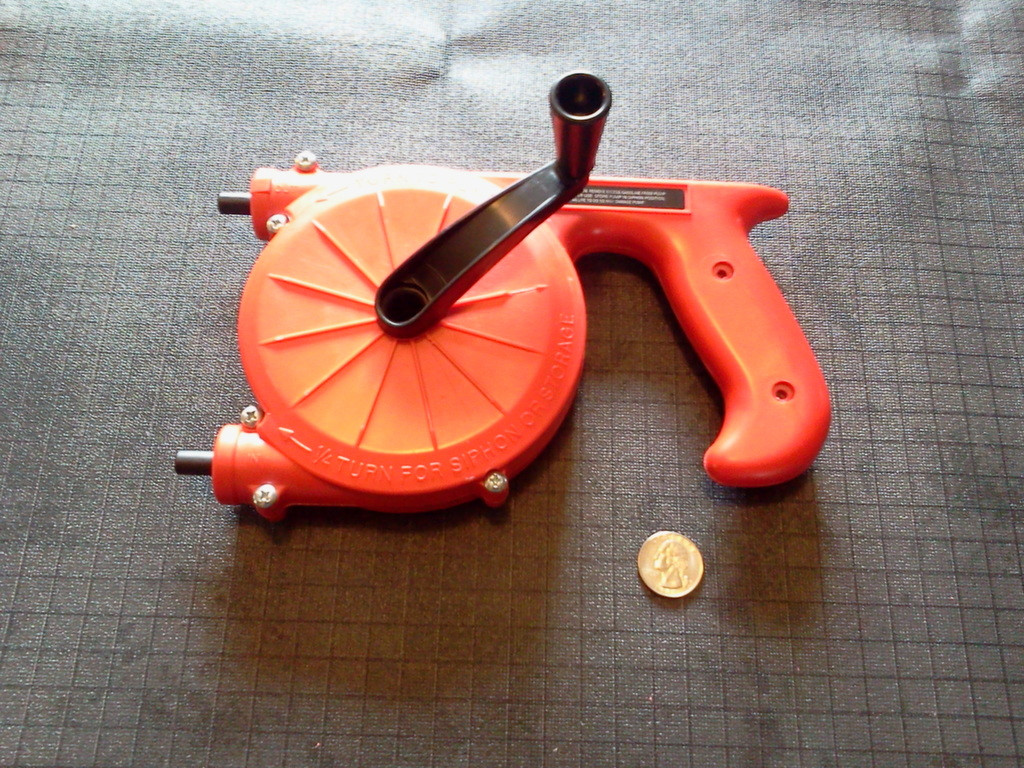

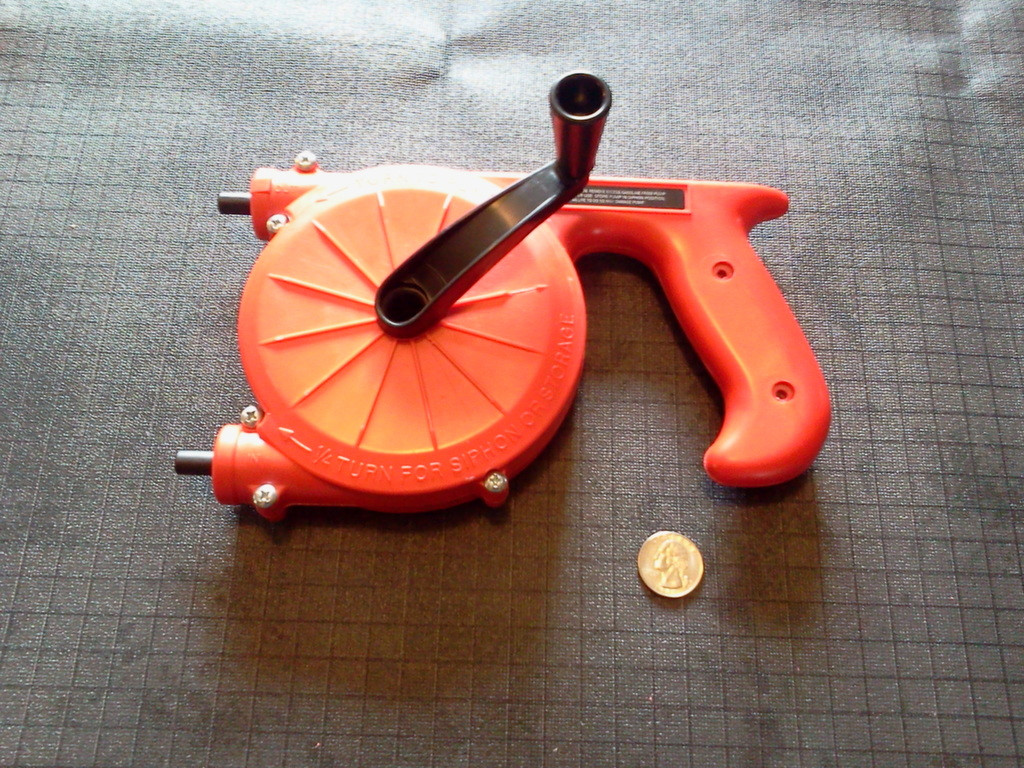

I bought the Ace pump, and took a look inside.

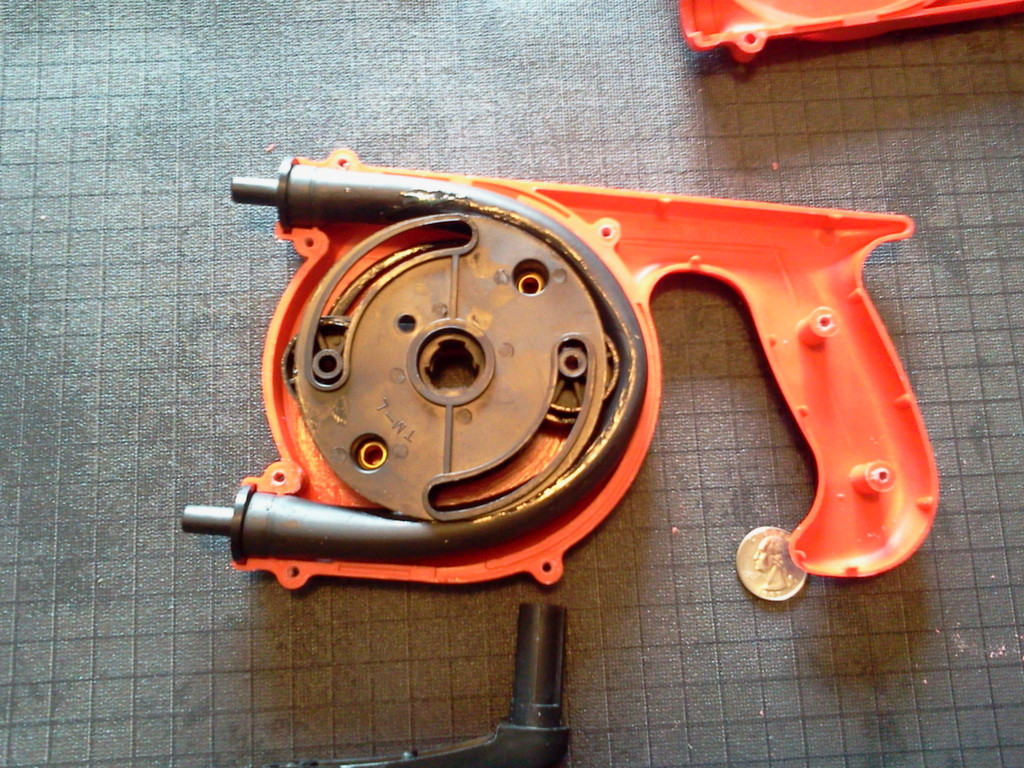

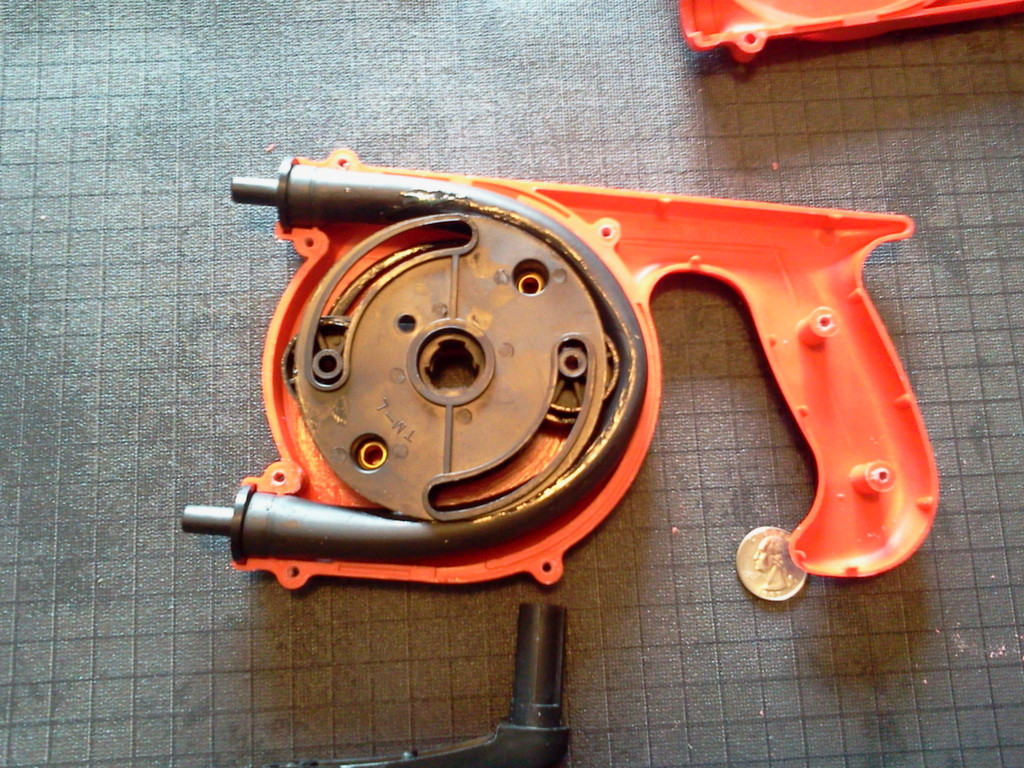

It WAS a peristaltic pump, just like I thought.

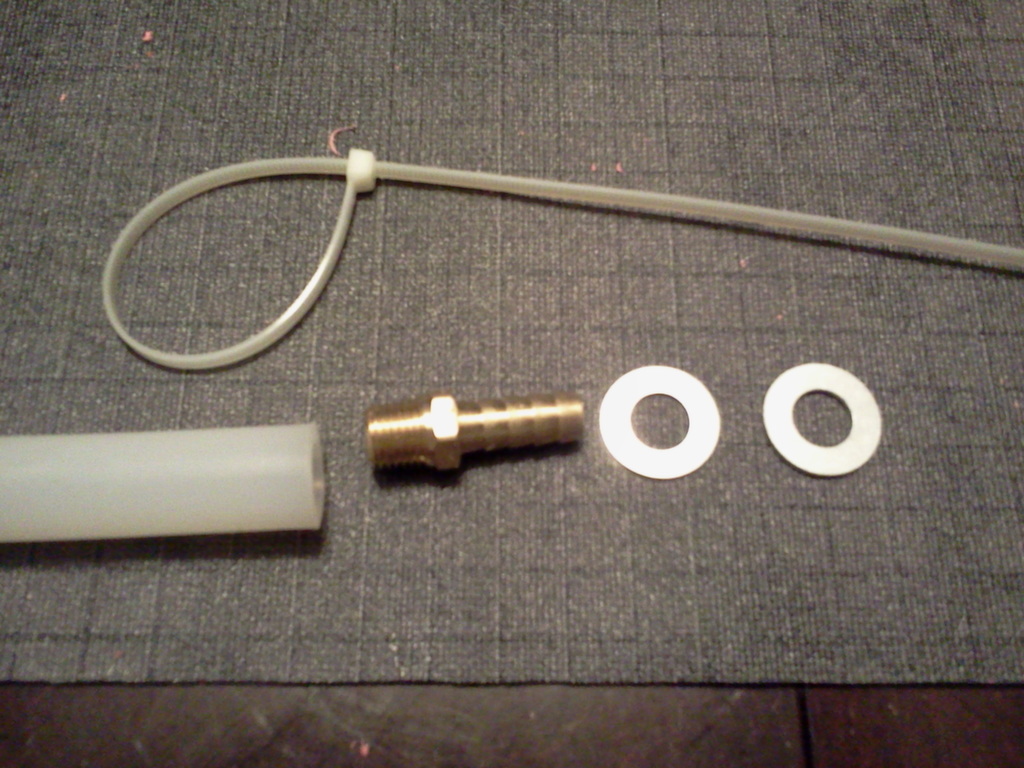

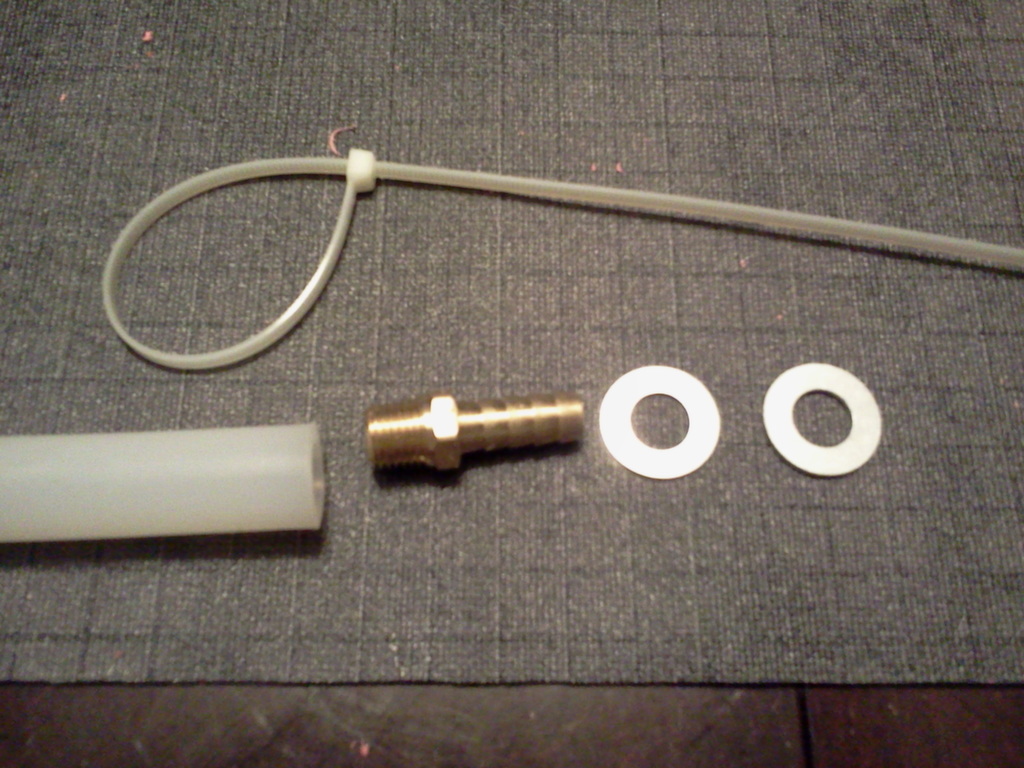

I replaced the plastic parts with brass/steel and replaced the tubing with 1/2'' ID silicon tubing. For the brass adapter, I used a 1/2'' threaded to 3/8'' barbed, simply because the hardware store was out of the adapters that were barbed on both ends. It still worked. I forget what size the washers were, I brought the plastic part with me to the hardware store and compared sizes...

Pieces all lined up.

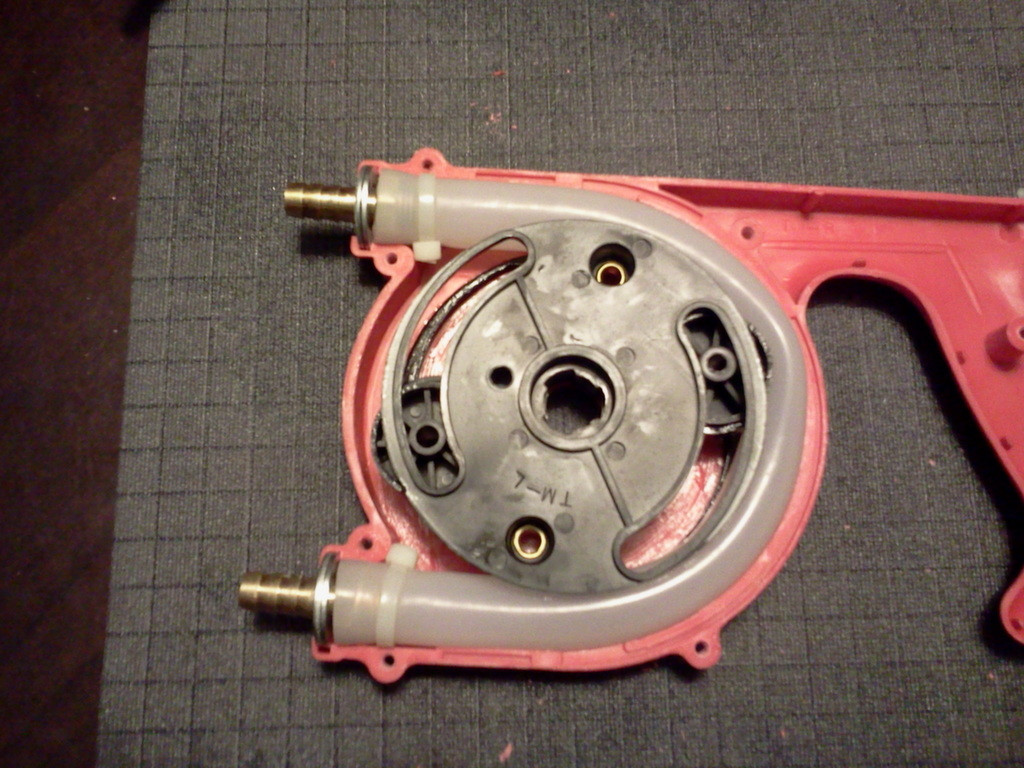

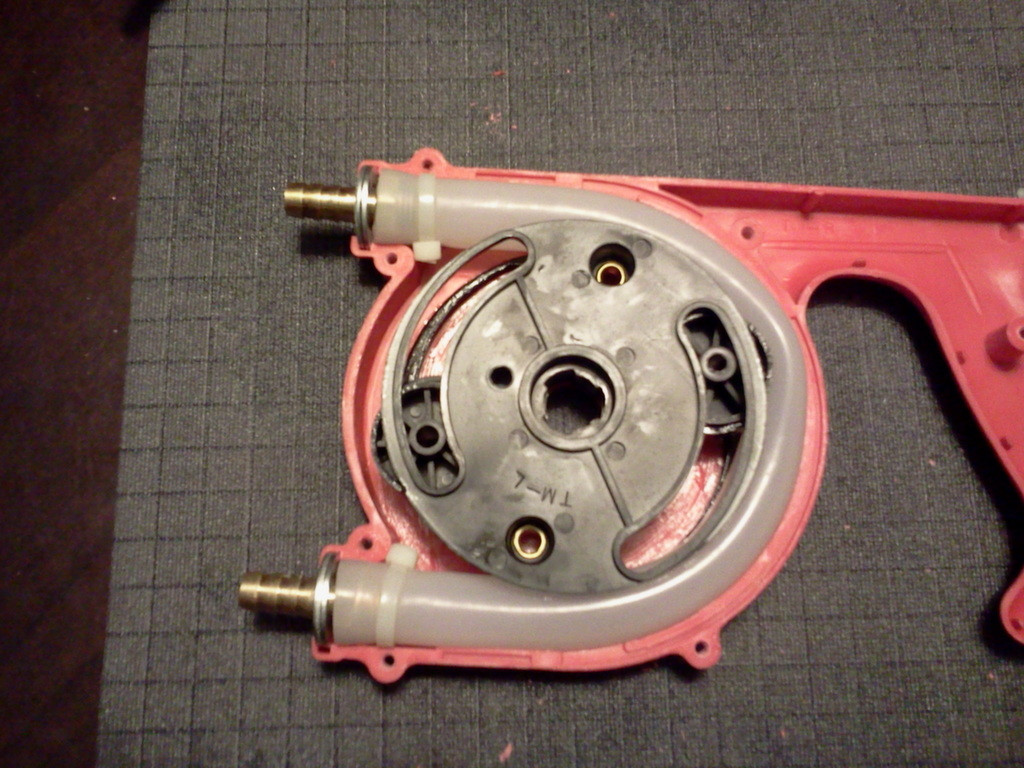

End assembly. Do this on both ends. Tube length is 11", if I remember correctly.

New parts in place.

The new parts work just as well as the old ones. Hurray!!!

The next step was to modify the handle so it could hook up to a power drill.

Drilled a hole, carved down to it with a shop knife.

Sacrificed a #4 Allen wrench and a random nut as a spacer to keep things centered.

Dumped epoxy over the whole thing and left it to set.

Once the epoxy cures entirely, I'll do some hot water tests and try to get a concrete number for the pumping rate.

Several months later, I finally got off my lazy bum and tried to make this idea a reality.

For those that just want the quick and dirty, it's a self-priming peristaltic pump that can be hand driven, or modded to run with an electric drill. It also can be used to start a siphon, and then open up to let the siphon run. I haven't done serious tests yet, but 1.5 to 2 Gal/min (6 to 8 L/min for those across the pond) seems like it's capacity. I'm not sure how high it can pump vertically (it's head) but it should be adequate for most homebrewing purposes.

Teardown and build Pictures!

I bought the Ace pump, and took a look inside.

It WAS a peristaltic pump, just like I thought.

I replaced the plastic parts with brass/steel and replaced the tubing with 1/2'' ID silicon tubing. For the brass adapter, I used a 1/2'' threaded to 3/8'' barbed, simply because the hardware store was out of the adapters that were barbed on both ends. It still worked. I forget what size the washers were, I brought the plastic part with me to the hardware store and compared sizes...

Pieces all lined up.

End assembly. Do this on both ends. Tube length is 11", if I remember correctly.

New parts in place.

The new parts work just as well as the old ones. Hurray!!!

The next step was to modify the handle so it could hook up to a power drill.

Drilled a hole, carved down to it with a shop knife.

Sacrificed a #4 Allen wrench and a random nut as a spacer to keep things centered.

Dumped epoxy over the whole thing and left it to set.

Once the epoxy cures entirely, I'll do some hot water tests and try to get a concrete number for the pumping rate.