GHBWNY

Well-Known Member

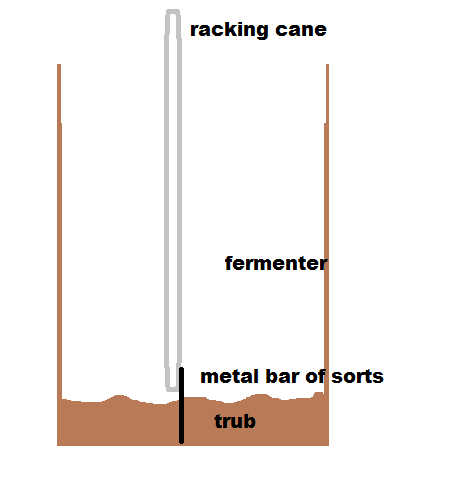

For awhile now, I've been kicking around ideas in my head <ouch> re: an insert for my 6.5 gal. ferm bucket that will prevent sucking up trub while racking to bottling bucket. Problem I've had up til now is that in a basically opaque plastic bucket, the wort is so dark I can't see the end of the racking cane or tell precisely how far away from the trub the tip of the cane is. If there was a surface in the murky depths of your wort you knew in advance was above the trub upon which you could safely set the end of the cane while the majority of liquid was transferred (at least until visibility becomes possible) it would virtually eliminate the liability of sucking up trub.

What I am imagining is a round screen of sorts, maybe on adjustable legs (or fixed height of 1"?), the top surface of which will theoretically sit above the trub and allow me to rest the tip of the racking cane on it while transferring without disturbing the trub. It could be as simple as a round piece of SS mesh on legs or a lip. The mesh would not impede fermentation and would be easy to insert, remove and clean/sanitize.

I've searched both here and online and haven't found anything like it available. Is the idea totally off-the-wall or not? If anyone knows of anything similar, I'd appreciate a pic, link, etc..

If not, I'm going to invent it --- maybe I just did? --- and call it...

"The TruBuster".

What I am imagining is a round screen of sorts, maybe on adjustable legs (or fixed height of 1"?), the top surface of which will theoretically sit above the trub and allow me to rest the tip of the racking cane on it while transferring without disturbing the trub. It could be as simple as a round piece of SS mesh on legs or a lip. The mesh would not impede fermentation and would be easy to insert, remove and clean/sanitize.

I've searched both here and online and haven't found anything like it available. Is the idea totally off-the-wall or not? If anyone knows of anything similar, I'd appreciate a pic, link, etc..

If not, I'm going to invent it --- maybe I just did? --- and call it...

"The TruBuster".