Yeah… embarrassingly it’s been in a holding pattern. Due to some hardware orders it got back burnered a bit… BUT it will be finished!! Hoping to use the holidays to get some time toward it!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BruControl: Brewery control & automation software

- Thread starter BrunDog

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I have had a Jacketed Fermentor on Order since February! Holding!Yeah… embarrassingly it’s been in a holding pattern. Due to some hardware orders it got back burnered a bit… BUT it will be finished!! Hoping to use the holidays to get some time toward it!

Is there a practical limit on concurent pin use on a Mega?

I would suspect that digital out control signals may be a limiting factor. I have search the internet and could Not find limit

I would suspect that digital out control signals may be a limiting factor. I have search the internet and could Not find limit

There are some bank limits IIRC. I can try to find it. If you can keep each pin to less than 15mA you should be ok. On the UniShield, there is no concern because the input current to the drivers is at the micro-amp level.

Only controlling SSRs or Proportinal Controllers.

- Joined

- Oct 25, 2008

- Messages

- 146

- Reaction score

- 22

How are others doing their rims return to the mash tun? I just bought a stout MT. It has a triclamp fitting on both outside and inside in the top of the vessel. They sell a triclamp tube with holes in it for recirc and sparge, but I read that it will clog if you recirc the mash through it. Sparging is fine.

I used a loc-line in my rig but it too clogs with grain in some holes. I'd make sure whatever ring you use has large enough holes to pass any grain bits.

Vorluft well untill it runs clean. I also have a Wort Filter 1.5" Tri Clover Compatible Strainer with 3" OD Body from Brewers Hardware You really need nothing when you are using RIMs or HERMs. < I attach 1/2 " silicone hose to the inside TC Fitting and lay it on top of the bed when recycling

- Joined

- Oct 25, 2008

- Messages

- 146

- Reaction score

- 22

Where do you install this, just before your rims tube?Vorluft well untill it runs clean. I also have a Wort Filter 1.5" Tri Clover Compatible Strainer with 3" OD Body from Brewers Hardware

MT drain valve out -> flow meter -> DC recirc pump -> RIM's Tube (vertical) -> MT In (top bulkhead via TC) -> MT inside bulkhead: Loc-Line adjusted just below surface. I don't use any type of filter in the RIM's recirc loop, everything is 1/2" straight through.How are others doing their rims return to the mash tun? I just bought a stout MT. It has a triclamp fitting on both outside and inside in the top of the vessel. They sell a triclamp tube with holes in it for recirc and sparge, but I read that it will clog if you recirc the mash through it. Sparging is fine.

- Joined

- Oct 25, 2008

- Messages

- 146

- Reaction score

- 22

Any recommendation on flowmeters for rims and sparge? I looked at the plastic adafruit one, but it is out of stock. There are a lot on Amazon, but it is not clear what you are getting and what the materials are. A lot of them seem to be for fuel filling applications.

Any recommendation on flowmeters for rims and sparge? I looked at the plastic adafruit one, but it is out of stock. There are a lot on Amazon, but it is not clear what you are getting and what the materials are. A lot of them seem to be for fuel filling applications.

I use this one, I'm not using it for volume calculations just as a flow reference: https://www.amazon.com/DIGITEN-Sens...efix=gredia+gr-201+flow+meter,aps,279&sr=8-31

It looks like the same one.

- Joined

- Oct 25, 2008

- Messages

- 146

- Reaction score

- 22

Great, thanks for the link.I use this one, I'm not using it for volume calculations just as a flow reference: https://www.amazon.com/DIGITEN-Sensor-Switch-Flowmeter-Counter/dp/B00VKATCRQ/ref=sr_1_31?crid=QQX6PC1WEP5I&keywords=Gredia+GR-201+flow+meter&qid=1640727660&sprefix=gredia+gr-201+flow+meter,aps,279&sr=8-31

Same one that I use as well, so sayeth amazon when I followed the link

A bit pricy but no moving parts

https://www.ebay.com/itm/SM6001-IFM...8985?_trksid=p2349526.m4383.l4275.c2#viTabs_0

https://www.ebay.com/itm/SM6001-IFM...8985?_trksid=p2349526.m4383.l4275.c2#viTabs_0

Love these. You can find some cheaper. BUT... check the fittings needed - they are often proprietary adapters for extra $$ and take up length. Also, check the output matches what you need. I wanted to use on my personal rig but the resolution at low flow was too low... cant get an effective measurement at fly sparge rates ~ 1 qpm.

MLT Out > Valve > Pump > Wort Strainer > Valve > HERMS Coil or RIMs > Mash Return MLTWhere do you install this, just before your rims tube?

Only issue I see with a strainer is the dead volume it contains. It’s ultimately lost unless you sparge through it too.

RiverCityBrewer

Well-Known Member

FYI, Blichmann quick connectors fit them fine and make for as compact as a connection as you can get.

Edit: For reference, here are some pictures.

Edit: For reference, here are some pictures.

Last edited:

I move the Wort from the MLT to the Brew Kettle through the filter. Not much left. My MLT is now bottom drain so I no longer have the 1.26 gal dead space. We normally brew 22 to 27 gal batches so that loss in not an issue. We used to take all the dead space into consideration, flushing when we could. We have a fixed manifold that we also flush. We simply added grain and volume to get the desired final fermentor volume.Only issue I see with a strainer is the dead volume it contains. It’s ultimately lost unless you sparge through it too.

- Joined

- Oct 25, 2008

- Messages

- 146

- Reaction score

- 22

It looks like it is limited to 158F. Do you use it for mash and sparge?A bit pricy but no moving parts

https://www.ebay.com/itm/SM6001-IFM...8985?_trksid=p2349526.m4383.l4275.c2#viTabs_0

RiverCityBrewer

Well-Known Member

I use the IFM SM6004 series which can be found for <$50 fairly easily. Main difference is 4-20ma outputs instead of pulse. Wetted parts are 316 SS, PEEK, and FKM, all of which have temp ratings well over 200F, so I'm guessing the media temperature rating has more to do with the electronics. To try and allow the most heat shedding possible, I mounted the sensors in the best free air space I could find. All that said, I run them on my HLT, MLT, and kettle and have pushed and sustained temps up well over 200F with no issues.

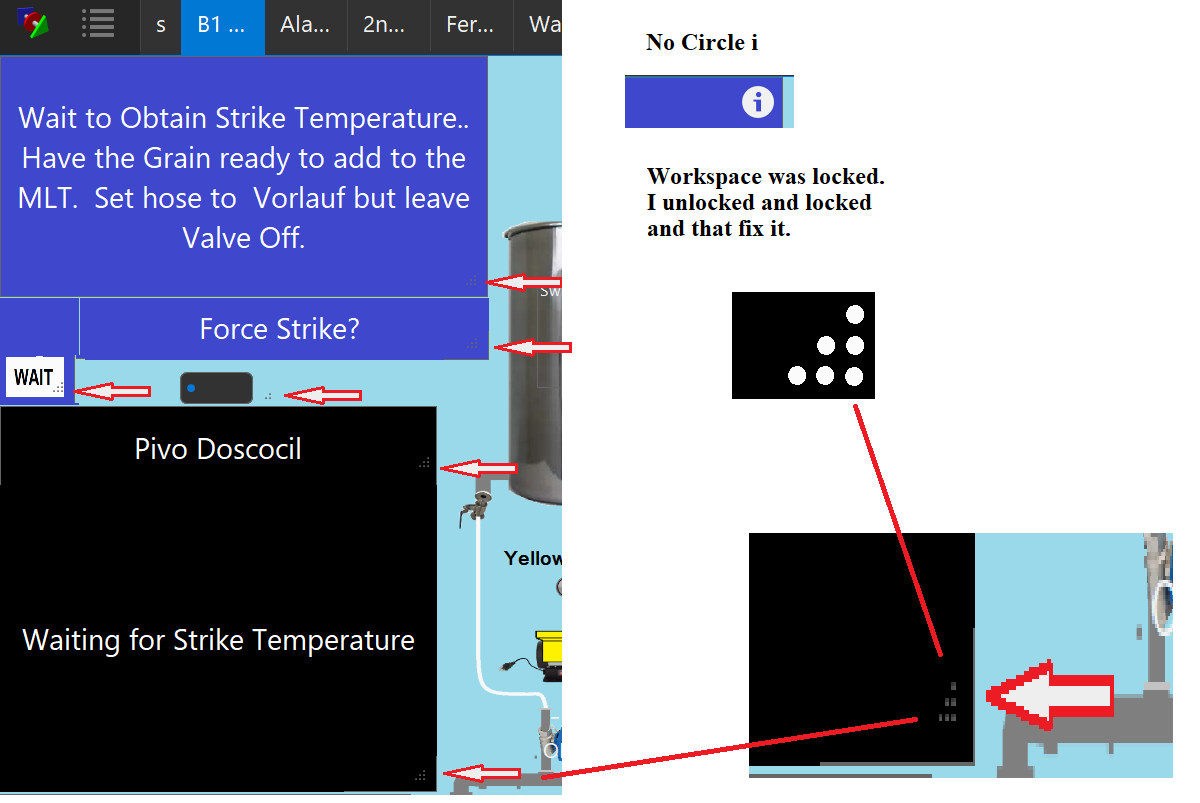

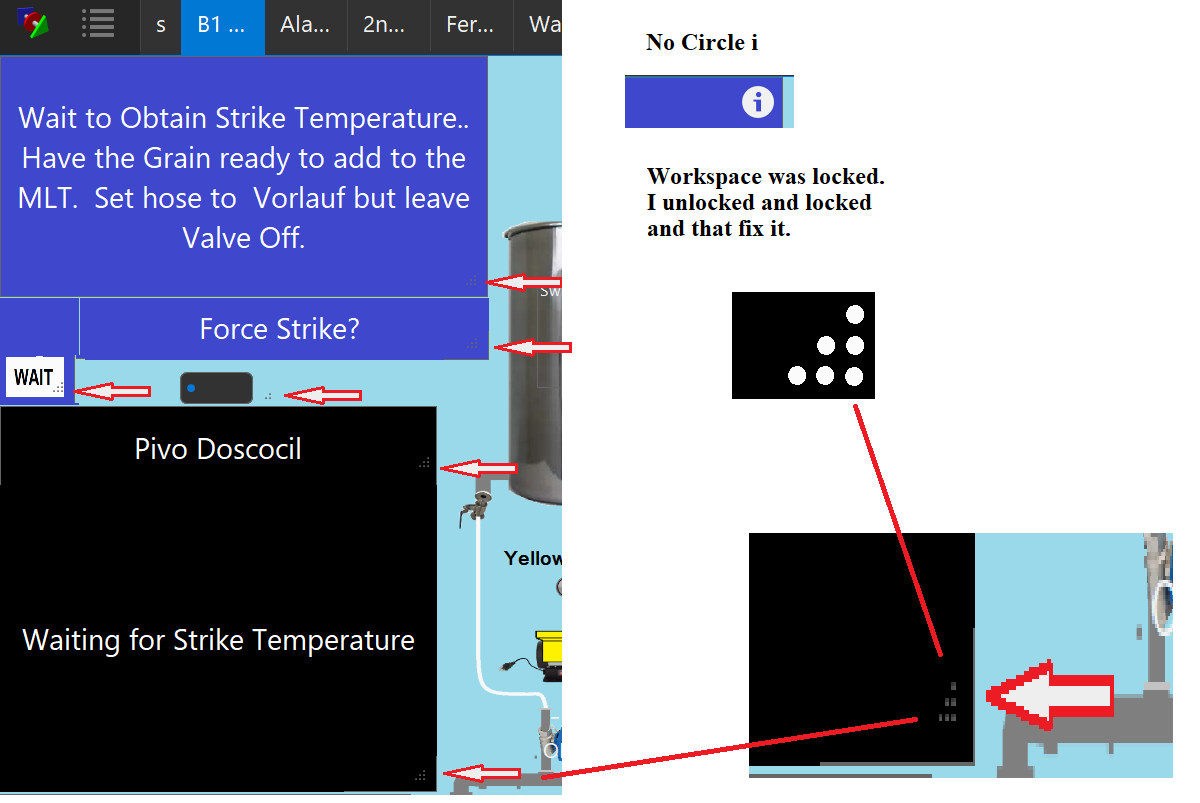

I still have issues with Elements resizing on their own. I just happen to notice that the little move dot trianges in the bottom right of the Element were there even though the workspace wqas locked, I unlocked and relocked, and the move widget disappeared as it was supposed to, This is the first time I noticed this.

Can you post or send pics/screen shots of what you are seeing?

unfortunately not. If it happens again I will take a screen shot. This is a replicate of what I saw: I could resize while locked

Just opened BruControl. Did not use the Lock or Unlock at the top. It was locked, I ran a few scripts (starting ones) and I noticed the little resize widget were on all the Elements) Once again, unlocked and relocked and issue gone. I closed BruControl. I opened BruControl and the Widgets once again (no scripts run) were there even though it was locked. This was version 1.1 Build 22 . I will now Open BruConrol and toggle the Lock Icon fcrom now on.

Attachments

ooob44

Member

@oakbarn @BrunDog I observe the same thing. If you lock the workspace, close BruControl, then start BruControl, the workspace will still be locked when the software launches but the elements are able to be resized via mouse in the bottom right corner of the element. If you unlock then relock the workspace, the ability to resize will go away as intended.

This may be a cuase of all the resizing issues I have been having regarding when I am working on the workspaces, It may have been that I was resizing Elements when it was locked and I was not paying attention. I have my resize to 1 x 1 when I am building.@oakbarn @BrunDog I observe the same thing. If you lock the workspace, close BruControl, then start BruControl, the workspace will still be locked when the software launches but the elements are able to be resized via mouse in the bottom right corner of the element. If you unlock then relock the workspace, the ability to resize will go away as intended.

OK, got it. Thanks!

exoticatom

Well-Known Member

unfortunately not. If it happens again I will take a screen shot. This is a replicate of what I saw: I could resize while lockedView attachment 754206

Hi all,

@BrunDog

My setup is to start BC after reboot. So if login to terminal session of my PC, after the restart, I have the same issue, always.

Check this video:

If you unlock/lock it disappears.

cheers evryone

- Joined

- Oct 25, 2008

- Messages

- 146

- Reaction score

- 22

So these are npt threads without taper and an oring to seal, so they work with the BSP fitting on the SM6004?FYI, Blichmann quick connectors fit them fine and make for as compact as a connection as you can get.

Edit: For reference, here are some pictures.

RiverCityBrewer

Well-Known Member

Yes, that's correct.

dstein1nine

New Member

- Joined

- Jun 30, 2021

- Messages

- 4

- Reaction score

- 0

Has anyone tried interfacing a Coriolis flow meter via Profibus DP and the mega unishield? Asking for a friend..

RiverCityBrewer

Well-Known Member

I did it via modbus and node red....

dstein1nine

New Member

- Joined

- Jun 30, 2021

- Messages

- 4

- Reaction score

- 0

Thanks for the reply! Unfortunately I believe my meter can only output via Profibus DP (Endress+Hauser promass 83M). I've never worked with PLCs so I was just curious if anyone knew of any software that can run on a virtual machine that could simulate the communication protocol so I would be able to read the meter without getting an actual PLC? I see that there is a beta node red for Profibus DP, but it looks like i would still need a Siemens PLC and adapter to communicate. I appreciate the feedback.I did it via modbus and node red....

Thanks

Profibus runs on RS485 - the physical connection can be made via a shield, but I don't know about the communication layer, especially if it needs to be a master. There are multiple videos / project reviews online, but I didn't dig in to see what it would take.

RiverCityBrewer

Well-Known Member

I'm not familiar with Endress+Hauser, but many sensors with *newer* busses have a fallback to modbus. You might poke around the manual for your specific model and see if that is an option. If you can output modbus, I can help you get it into node-red and thus BC (if you have the correct license).

dstein1nine

New Member

- Joined

- Jun 30, 2021

- Messages

- 4

- Reaction score

- 0

Thanks for the feedback. I'll keep digging into it and see what I can put together.

Similar threads

- Replies

- 29

- Views

- 5K

- Replies

- 51

- Views

- 8K