I did download the latest version yesterday before I started playing with the GUI.Hi @crane,

Do you have the latest version? We added that ability recently. I think the primary value shows in the digital gauge (would need to test to confirm).

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BruControl: Brewery control & automation software

- Thread starter BrunDog

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

rkhanso

Well-Known Member

- Joined

- Jan 24, 2017

- Messages

- 776

- Reaction score

- 175

What would be an acceptable SSR or extra components added with a "typical" SSR to make it suitable to be used to control a 5k BTU window AC unit for a glycol chiller? I've heard about inductive loads - and that a window AC unit would be one...but didn't realize that a regular cheap SSR from ebay is not the proper one to use.

What would be an acceptable SSR ... to be used to control a 5k BTU window AC unit for a glycol chiller? I didn't realize that a regular cheap SSR from ebay is not the proper one to use.

I would consider a relay for this application—presumably the AC unit will not be cycled on and off frequently. Besides, it will sound cool!

I have used a cheap SSR similar to the one below to run my keg fridge for years. That is a similar kind of load I would think (compressor).

https://www.amazon.com/TIHOOD-SSR-40DA-Solid-State-24-380V/dp/B07PDHMJC9/ref=sr_1_1_sspa?crid=BNLP8LVOTSR2&keywords=fotek+ssr-40da&qid=1560613502&s=gateway&sprefix=fotek,aps,148&sr=8-1-spons&psc=1

Maybe not the most robust/best answer but it is what I did.

https://www.amazon.com/TIHOOD-SSR-40DA-Solid-State-24-380V/dp/B07PDHMJC9/ref=sr_1_1_sspa?crid=BNLP8LVOTSR2&keywords=fotek+ssr-40da&qid=1560613502&s=gateway&sprefix=fotek,aps,148&sr=8-1-spons&psc=1

Maybe not the most robust/best answer but it is what I did.

I did download the latest version yesterday before I started playing with the GUI.

Tested this and confirmed. Were you able to get it working as you wanted?

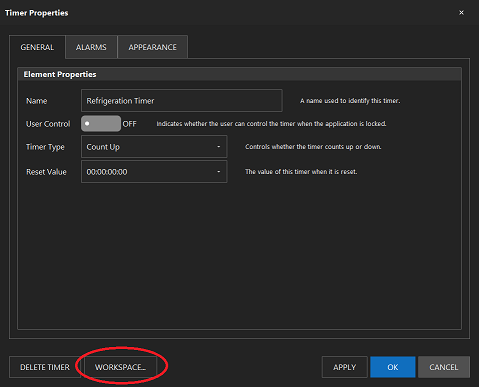

Yup I found it was in the general tab instead of the appearance tab in the element settings.Tested this and confirmed. Were you able to get it working as you wanted?

We uploaded v1.1.1 today... this corrects the Global and Inspector data recording issue where it records those values into the data logs up to 20x per second. We created a default of 1 second per data point. This will reduce overhead (and disk space)!

I suggest users of Global variables and Inspectors upgrade ASAP. For users who do not... no rush.

I suggest users of Global variables and Inspectors upgrade ASAP. For users who do not... no rush.

if someone with a feather M0 could put it in debug %1&14; before doing the network setup with %0&15; and show me the output, I would appreciate it... I think my M0 died... it takes firmware, it charges battery, it takes network config, but never connects... debug after programming network shows what I think is goofy stuff...

Angus Grant

Well-Known Member

We uploaded v1.1.1 today... this corrects the Global and Inspector data recording issue where it records those values into the data logs up to 20x per second. We created a default of 1 second per data point. This will reduce overhead (and disk space)!

I suggest users of Global variables and Inspectors upgrade ASAP. For users who do not... no rush.

Does this also include the fix for graphs only updating when global variable is on the same active workspace?

No big deal if not and I'm happy to wait, it would just be nice to clear up my "user" workspace, and have a "config" workspace which my user never looks at.

Actually, it might be nice to have a setting to hide workspaces when the lock button is clicked, so in "run" mode users never see those workspaces.

... It might be nice to have a setting to hide workspaces when the lock button is clicked, so in "run" mode users never see those workspaces.

+1

No this doesn’t fix the graph issue you mentioned. It’s in the list though.

Regarding the hidden workspace, that’s a good idea - we’ll queue it.

Regarding the hidden workspace, that’s a good idea - we’ll queue it.

I am in the process of setting up some proportional valves and have a question with regards to PWM Outputs listed in the V 1.1 Wiring Map. I cannot find the PWM option in the pull down menu while trying to set up Pins 11,12,13,44. I realize there are alternative pins I could use but am I missing something maybe a revision somewhere with respect to these specific pins? I'm using a RobotDyn MEGA 2560 board, firmware V45 and V1.1 software

Thanks

Thanks

Last edited:

I am in the process of setting up some proportional valves and have a question with regards to PWM Outputs listed in the V 1.1 Wiring Map. I cannot find the PWM option in the pull down menu while trying to set up Pins 11,12,13,44. I realize there are alternative pins I could use but am I missing something maybe a revision somewhere with respect to these specific pins? I'm using a RobotDyn MEGA 2560 board, firmware V45 and V1.1 software

Thanks

I'm showing PWM for all of those pins on my MEGA 2560 (I happen to be using the RobotDyn board as well but that is not part of the pin function availability). IS this some sort of wiring map issue from a pre 1.1 installation?

Do you already have them defined? You can only have one mode Device Element per pin.

@BrunDog @VacationLand

Those particular pins were vacant, however I was using a previous software version V1.1.0 When I installed V1.1.1 it did allow PWM on PIN 44 however the others no dice. I did a complete uninstall of both V1.1.0 and V1.1.1 but I made a backup of the Data folder from 1.1.0 first. I then replaced the backup folder in the newer version (V1.1.1). After a reinstall all is good as I now have PWM listed on the pins mentioned, however I lost my device setup I thought I had backed up during the update. Not sure what went wrong? I still have the Data Folder from the previous install but for some reason I cant get it to repopulate the new work space. Anyway looks like I'll have to start from scratch and this time I will document with a good old fashion hard copy

Thanks again!!

Those particular pins were vacant, however I was using a previous software version V1.1.0 When I installed V1.1.1 it did allow PWM on PIN 44 however the others no dice. I did a complete uninstall of both V1.1.0 and V1.1.1 but I made a backup of the Data folder from 1.1.0 first. I then replaced the backup folder in the newer version (V1.1.1). After a reinstall all is good as I now have PWM listed on the pins mentioned, however I lost my device setup I thought I had backed up during the update. Not sure what went wrong? I still have the Data Folder from the previous install but for some reason I cant get it to repopulate the new work space. Anyway looks like I'll have to start from scratch and this time I will document with a good old fashion hard copy

Thanks again!!

Last edited:

The configuration file will work from v1.0 so long as the interface type is a match. If you email us your previous and current configuration files, we can combine them so you don’t have to recreate all your stuff.

Thanks for your offer to combine my files but instead I spent the afternoon adding the devices into a new install. It wasn't too bad and the way I look at it, this was a good learning experience. If/when future updates are made to the current version, (so I don't have to do this all again) my understanding is V1.1.1 does an auto backup of the config files with a 30 day history? To apply to a (future) revision I would simply make a copy of my backup config files, install the new update and import the former config files into the update as per instructions in the user manual. Would this be the correct process?

Last edited:

I can’t predict too far into the future... but you should just install the updated version without doing anything else. That is how this upgrade works but for some reason yours didn’t work that way.

It would be nice to be able to select a counter elements flow rate value for the dead band control input. I would like to use the dead band control to drive a DC pump PWM control based off of a counter flow meter.

I have both a counter flow meter and a mass flow meter and the MFM's min flow is too high for driving my pump at it's lowest speeds, which is why I would like to switch to the counter flow meter for the dead band control input. The dead band control works great with the MFM as the input as long as I stay above the MFM's min flow rate.

I have both a counter flow meter and a mass flow meter and the MFM's min flow is too high for driving my pump at it's lowest speeds, which is why I would like to switch to the counter flow meter for the dead band control input. The dead band control works great with the MFM as the input as long as I stay above the MFM's min flow rate.

Yes we can add counter flow rate to the PID, Hysteresis, and Deadband outputs.

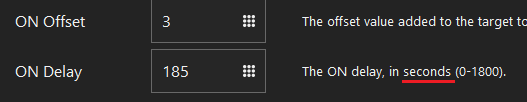

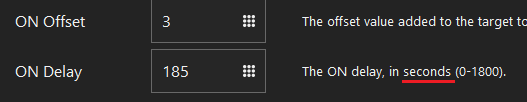

The "On Delay" time allowed (1800) for an Hysteresis Output Element seems way to short. I generally used these for compressors or mechanical contractors. 1.8 seconds is too small a time to insure not "short cycling". For my compressors, I use about 15 minutes (900000 milliseconds) as a "On Delay". I know that you can set the offset to control this as well, but it would seem that I should be able to choose the "On Delay" I want. Why are these (and other things) limited in range? It would seem that you would have to write code to enforce the limitations rather that limiting it to an long integer. You never "know" what an end user may use something for, so limitations can prevent "outside" the box implementations.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

DUDE. Please. It clearly states that delay is in seconds. Please RTFM. 180 seconds is 3 minutes and 1800 is 30 minutes....

Dude, you are correct. I ASSumed milliseconds.What the TFM says:DUDE. Please. It clearly states that delay is in seconds. Please RTFM. 180 seconds is 3 minutes and 1800 is 30 minutes....

"There are four specific properties for a Hysteresis Output. The first is the ‘Input Device’ selection, which is the Device Element’s input signal to be compared to the target. The second is the ‘Target’, which is the input signal the hysteresis output will try to achieve by turning the element’s device ON or OFF. The third is the ‘ON Offset’, which is difference from the Target where the input signal value upon which the output will turn ON. Fourth is the ‘On Delay’, which is the minimum period of time for the output to be turned ON once it was turned off. This is designed to prevent short-cycling of certain devices, like refrigeration compressors, which need a delay between power cycles".

It is clear on the Element Properties once you know to look. I wish the slots were different for seconds or milliseconds.

Last edited:

Ok, I'll admit we could state it explicitly in the manual, and will try to make these changes, but I'm not sure we could make it any clearer in the software.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

The screen shot like that IN the manual shows the same thing.

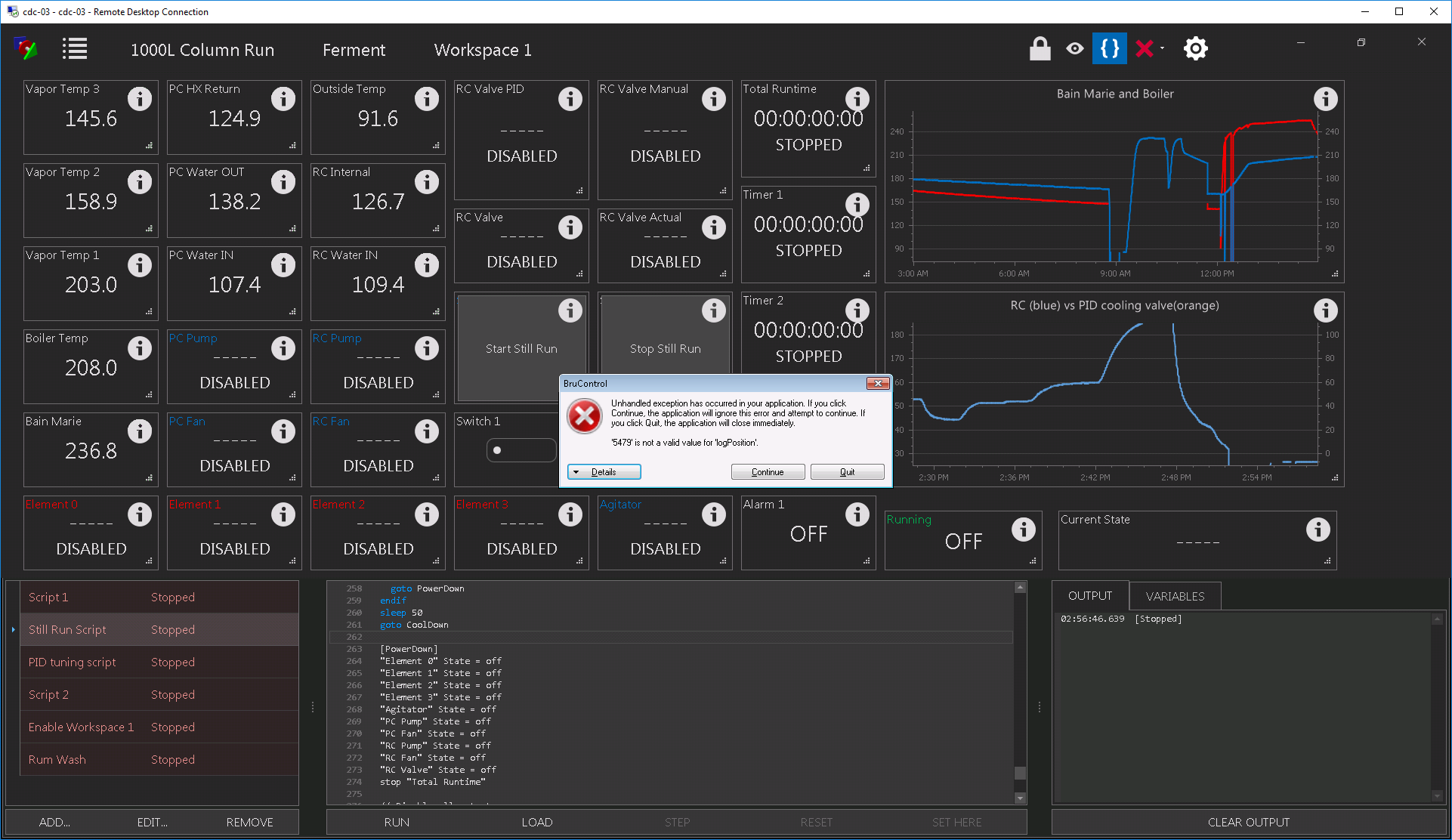

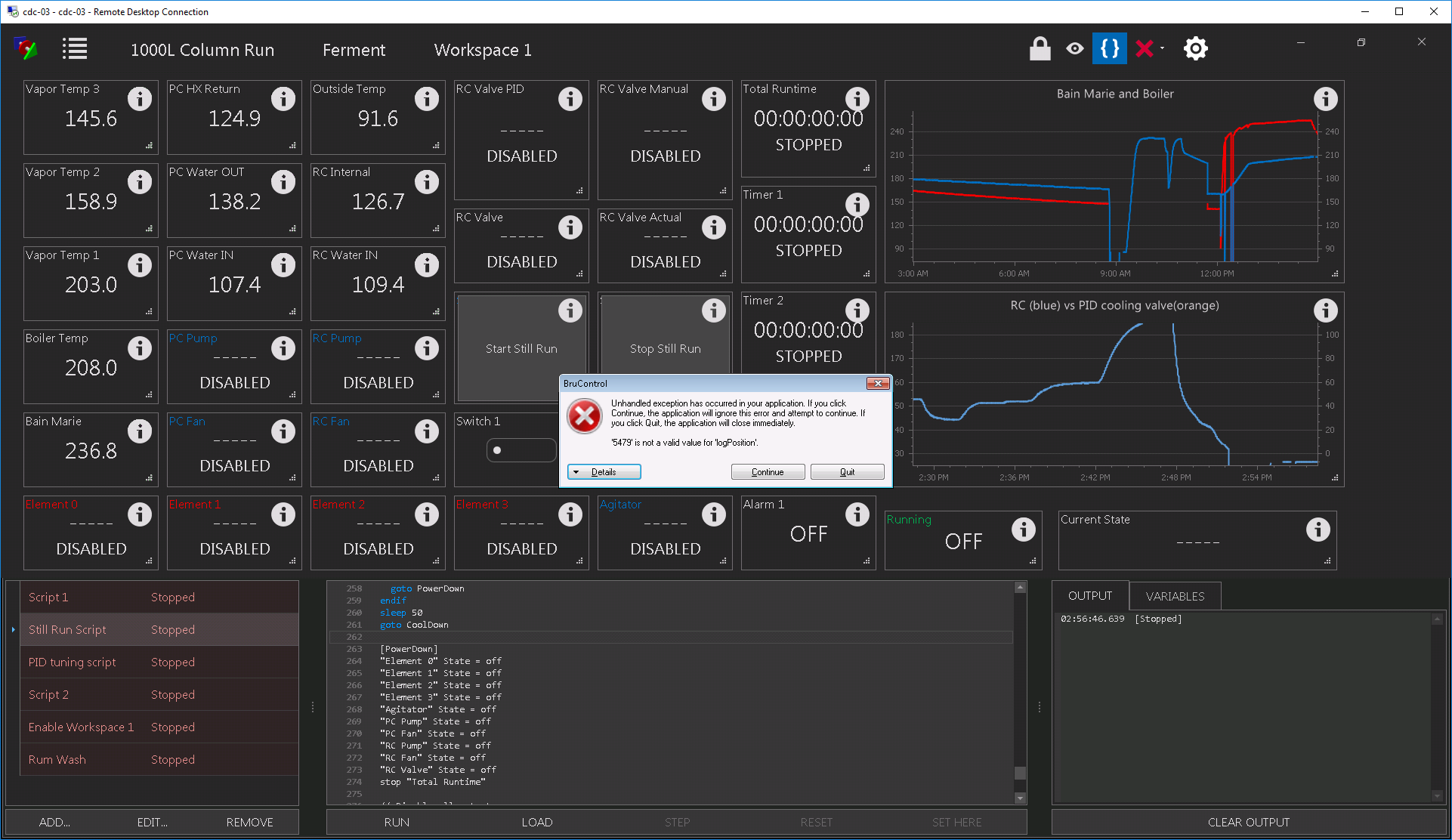

FYI - if you are cutting and pasting you scripts to from notepad and you hit the shift key when typing the left bracket and put in a left squigly bracket, you will make a software bomb that crashes BC without running the script...

I'm not able to duplicate this. Can you post the exact steps you are taking to induce this crash?

Just gonna drop this here...

https://www.raspberrypi.org/products/raspberry-pi-4-model-b/[URL]https://www.raspberrypi.org/products/raspberry-pi-4-model-b/[/URL]

Cheers!

https://www.raspberrypi.org/products/raspberry-pi-4-model-b/[URL]https://www.raspberrypi.org/products/raspberry-pi-4-model-b/[/URL]

Cheers!

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

Just gonna drop this here...

https://www.raspberrypi.org/products/raspberry-pi-4-model-b/https://www.raspberrypi.org/products/raspberry-pi-4-model-b/

Cheers!

Too bad the cart is before the horse on this one. Isn't there issues with the OS and this, meaning its not fully working?

Once you see it, it is easy. I am just not "used" to seeing seconds only for a time, rather than 1800 seconds displayed as I would have preferred something like 30:00. Since it is an OnDelay to prevent short cycling, the minimum delay could be in minutes and not seconds regardless. In a lot of cases, milliseconds is the norm in BruControl, therefore I made the ASSumption.Ok, I'll admit we could state it explicitly in the manual, and will try to make these changes, but I'm not sure we could make it any clearer in the software.

View attachment 632466

I did notice that you can use a script to set a value higher than 1800:

"Big Mac-E" OnDelay = 3600

Would that value work for an hour delay or is the 1800 seconds a true limit?

i probably has to do with the characters after the {...I'm not able to duplicate this. Can you post the exact steps you are taking to induce this crash?

you will see the character near the end in the CoolDown_a declaration

If you cut and paste this in, it will crash BC

Code:

new value StopTemp

new string CurrentState

StopTemp = 207

reset "Timer 1"

Stop "Timer 1"

restart "Total Runtime"

"Stop Still Run" State = false

// Enable all devices needed

"Element 0" Enabled = true

"Element 1" Enabled = true

"Element 2" Enabled = true

"Element 3" Enabled = true

"Agitator" Enabled = true

"Bain Marie" Enabled = true

"Boiler Temp" Enabled = true

"Vapor Temp 1" Enabled = true

"Vapor Temp 2" Enabled = true

"Vapor Temp 3" Enabled = true

"PC Water IN" Enabled = true

"PC Water OUT" Enabled = true

"PC HX Return" Enabled = true

"PC Pump" Enabled = true

"PC Fan" Enabled = true

"RC Water IN" Enabled = true

"RC Internal" Enabled = true

"RC Pump" Enabled = true

"RC Fan" Enabled = true

"RC Valve" Enabled = true

"AlarmOut 1" Enabled = true

// start the still run

[Heating Up]

CurrentState = "Heating Up"

sleep 1000 // pause before energizing contactor

"Element 0" State = on

sleep 1000 // pause before energizing contactor

"Element 1" State = on

sleep 1000 // pause before energizing contactor

"Element 2" State = on

sleep 1000 // pause before energizing contactor

"Element 3" State = on

[State1]

if "Stop Still Run" State == true

goto CoolDown

endif

if "Start Still Run" State == true

sleep 1000

goto State2

endif

if "Bain Marie" Value > 230 // energize Agitator

if "Agitator" State == off

"Element 0" State = off

"Element 1" State = off

"Element 3" State = off

sleep 1000

"Agitator" State = on

sleep 1000

"Element 0" State = on

sleep 1000

"Element 1" State = on

endif

endif

if "Bain Marie" Value > 248 // Lower power by one element

if "Element 3" State == on

"Element 3" State = off

endif

endif

if "Bain Marie" Value > 250 // Lower power by one element

if "Element 2" State == on

"Element 2" State = off

endif

endif

if "Bain Marie" Value > 252 // Lower power by one element

if "Element 1" State == on

"Element 1" State = off

endif

endif

if "Bain Marie" Value > 270 // Kill power and alarmif temp actually reaches 250F

"Element 0" State = off

"Element 1" State = off

"Element 2" State = off

"Element 3" State = off

"Alarm 1" Active = true

goto CoolDown

endif

if "Boiler Temp" Value > 170 // exit to State2 when BK temp reaches 170

goto State2

endif

if "Vapor Temp 1" Value > 160 // exit to State2 when V1 temp reaches 160

goto State2

endif

sleep 50

goto State1

if "Element 3" State == on

"Element 3" State == off

endif

if "Element 2" State == on

"Element 2" State == off

endif

[State2]

CurrentState = "Heating 2nd stage"

if "Stop Still Run" State == true

goto CoolDown

endif

if "Start Still Run" State == true

sleep 1000

goto State3

endif

if "Boiler Temp" Value > 212 // exit and alarm if BK temp reaches 212

"Alarm 1" Active = true

goto CoolDown

endif

if "Vapor Temp 1" Value > 210 // exit and alarm if V1 temp reaches 210

"Alarm 1" Active = true

goto CoolDown

endif

if "Vapor Temp 3" Value > 110 // exit to State3 when V2 temp reaches 165

goto State3

endif

sleep 50

goto State2

[State3]

CurrentState = "filling plates"

if "Stop Still Run" State == true

goto CoolDown

endif

if "Start Still Run" State == true

sleep 1000

goto State4

endif

if "Vapor Temp 3" Value > 130 // clear plates when V3 temp reaches 130

goto State4

endif

sleep 50

goto State3

[State4]

CurrentState = "clearing plates"

"Element 0" State = off

"Element 1" State = off

"Element 2" State = off

"Element 3" State = off

"Timer 1" Type = CountDown

"Timer 1" Value = 00:01:00

Start "Timer 1"

[State4a]

if "Stop Still Run" State == true

Stop "Timer 1"

goto CoolDown

endif

if "Start Still Run" State == true

sleep 1000

goto State5

endif

if "Timer 1" Value < 00:00:00

Stop "Timer 1"

goto State5

endif

sleep 50

goto State4a

[State5]

CurrentState = "Reflux"

"Element 0" State = on // 1 element should be plenty to run full reflux

"RC Pump" State = on // set up reflux PID

"RC Fan" State = on

//"RC Valve PID" Enabled = true

//"RC Valve PID" target = 150

"RC Valve Manual" Enabled = true

"RC Valve Actual" Enabled = true

"RC Valve" State = on

"Timer 1" Type = CountDown // start 1 hour reflux timer

"Timer 1" Value = 1:00:00

Start "Timer 1"

[State5a]

if "Stop Still Run" State == true

Stop "Timer 1"

goto CoolDown

endif

if "Start Still Run" State == true

sleep 1000

goto State6

endif

if "Timer 1" Value < 00:00:00

Stop "Timer 1"

goto State6

endif

sleep 50

goto State5a

[State6]

CurrentState = "Distill"

"Timer 1" Type = CountUp

restart "Timer 1"

if "PC Pump" State == off // Turn on pump

"PC Pump" State = on

endif

if "PC Water OUT" Value > 100 // turn on fan when needed

if "PC Fan" State == off

"PC Fan" State = on

endif

endif

[State6a]

if "Start Still Run" State == true

sleep 1000

goto CoolDown

endif

if "Stop Still Run" State == true

goto CoolDown

endif

if "Vapor Temp 1" Value >= StopTemp // exit to cooldown state when distillation finished

goto CoolDown

endif

sleep 50

goto State6a

[CoolDown]

CurrentState = "CoolDown"

"Element 0" State = off

"Element 1" State = off

"Timer 1" Type = CountDown

"Timer 1" Value = 00:03:00

Start "Timer 1"

{CoolDown_a]

if "Start Still Run" State == true

Stop "Timer 1"

sleep 1000

goto PowerDown

endif

if "Stop Still Run" State == true

Stop "Timer 1"

goto PowerDown

endif

if "Timer 1" Value < 00:00:00 // exit to cooldown state

Stop "Timer 1"

goto PowerDown

endif

sleep 50

goto CoolDown_a

[PowerDown]

"Element 0" State = off

"Element 1" State = off

"Element 2" State = off

"Element 3" State = off

"Agitator" State = off

"PC Pump" State = off

"PC Fan" State = off

"RC Pump" State = off

"RC Fan" State = off

"RC Valve" State = off

stop "Total Runtime"

// Disable all outputs

"Element 0" Enabled = false

"Element 1" Enabled = false

"Element 2" Enabled = false

"Element 3" Enabled = false

"Agitator" Enabled = false

"PC Pump" Enabled = false

"PC Fan" Enabled = false

"RC Pump" Enabled = false

"RC Fan" Enabled = false

"RC Valve" Enabled = false

"RC Valve PID" Enabled = false

"AlarmOut 1" Enabled = false

"Running" Enabled = false

stop "Still Run Script"Too bad the cart is before the horse on this one. Isn't there issues with the OS and this, meaning its not fully working?

It's just the announcement, it won't be shipping for around a month, so there may still be open issues being worked. But it's a big step in performance that could enable all kinds of usage models that the predecessors just lacked the gas to handle.

That said, I'm not looking forward to Debian 10, every time they release a new Raspbian there's all kinds of hell to pay with all the package updates breaking **** left and right. As soon as I lay my hands on a 4B I'll see if I can update Jessie's firmware to make it work...

Cheers!

purdman10

Well-Known Member

I exclusively run BC on a RPI 3B+. See my Feb 20 post.

i probably has to do with the characters after the {...

you will see the character near the end in the CoolDown_a declaration

If you cut and paste this in, it will crash BC

I verified this is correct. You have an open brace instead of an open bracket for section 'CoolDown_a' which is causing it to fail. This is a recoverable error so long as you select 'Continue' in the debugger and do not put your cursor back into the script window.

We'll fix this but in the meantime, don't put open braces in your scripts!

Once you see it, it is easy. I am just not "used" to seeing seconds only for a time, rather than 1800 seconds displayed as I would have preferred something like 30:00. Since it is an OnDelay to prevent short cycling, the minimum delay could be in minutes and not seconds regardless. In a lot of cases, milliseconds is the norm in BruControl, therefore I made the ASSumption.

I did notice that you can use a script to set a value higher than 1800:

"Big Mac-E" OnDelay = 3600

Would that value work for an hour delay or is the 1800 seconds a true limit?

We picked units that we thought matched the application best. There are applications where a seconds-only delay makes sense (like two motors powering on at the same time - this could make sure the circuit is not overloaded). Millisecond units doesn't make sense, nor do minutes in our estimation.

You can write what you like in a script... it doesn't mean it will work, so we recommend you pay attention to the limits. In this circumstance, the script will execute, but the value will be capped when it gets transmitted to the interface.

Just gonna drop this here...

https://www.raspberrypi.org/products/raspberry-pi-4-model-b/https://www.raspberrypi.org/products/raspberry-pi-4-model-b/

Cheers!

I'm not sure the allure of the RPi other than its cost. The reliability is meh (this is our experience - please refrain from grabbing your flame thrower) and it can't do much. Yes, its inexpensive... but when you are building automated equipment where you are spending likely into the thousands, saving $50 - $100 doesn't seem to make a lot of sense. My personal opinion anyway.

Edit: Oh...forgot the I/O. Yes, onboard I/O is nice. Problem is the OS is not real-time. So running time-critical applications poses a risk. Brewing is slow, so it's not really an issue admittedly. It would show up if you had a ton of PID's maybe.

Last edited:

Real time OS? Bit of red herring, ainnit? Meanwhile you're running BC on Windows!

Cheers!

Cheers!

Is it possible to move a "Device Element" from one Workspace to another? For my particular setup it would be nice to pick the device elements associated with a particular process from a master workspace and drag it across to the pertinent process workspace. I'm not trying to duplicate a device just trying to move it.

Is it possible to move a "Device Element" from one Workspace to another? For my particular setup it would be nice to pick the device elements associated with a particular process from a master workspace and drag it across to the pertinent process workspace. I'm not trying to duplicate a device just trying to move it.

v1.1+... element properties, bottom left corner:

Real time OS? Bit of red herring, ainnit? Meanwhile you're running BC on Windows!

Cheers!

I meant in context to the I/O. Micro-controllers will stay on time, assuring events occur as scheduled. I'd challenge anyone to measure duty cycle times on a micro vs. the RPi.

In terms of reliability - trust this is a #1 goal. I think we have seen really good reliability from Win10. Anyway, if RPi will deliver it, we'll go there. The interesting thing is the RPi 4 offers up to 4GB RAM - it will be $55 which is not exactly the savings it was before. You can get an AtomicPi for under $45 at this moment... but again I don't think we should be skimping on computer hardware that is running our automated equipment!

Last edited:

Similar threads

- Replies

- 29

- Views

- 6K

- Replies

- 51

- Views

- 8K