augiedoggy

Well-Known Member

lol I wondered if you old site server was running a 56k modem myself...

Sometimes incorrect host drivers will prevent devices from being identified properly.

The odd thing is that you connected BC through it via serial? The good news is once it is set up, you won't need to user serial anymore. Until we issue a new firmware that is...

I wish I could help because I too was confused when I first set mine up and it was the simpler usb setup (I had issues with the clone ch340 arduino substitute chip drivers) but once you finally get it sorted out it becomes pretty clear and and you will be glad you did..Here's the thing. I thought I connected via serial, but I'm ignorant enough at this point that I'm not sure I did. For instance, I didn't realize until you pointed it out that I needed to set up the Arduino to connect to my home wi-fi through the interface setup and not in BC. Once I realized I needed to do that, it became apparent my computer properly picked up the Arduino.

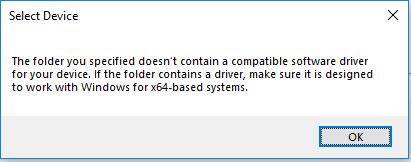

Here's something new I saw this morning. I'm kind of at a loss right now. I've read suggestions on the interwebs for holding down a reset button on the Arduino while plugging in the USB, then releasing the reset. I dunno at this point.

View attachment 583151

@TexasWine has the normal MEGA with the Atmel USB chip.

I'm using x64, shouldn't be an issue. Maybe try downloading the Arduino software (non-install version) and see if you can find the compatible driver in there: https://www.arduino.cc/download_handler.php?f=/arduino-1.8.5-windows.zip

Texas Wine when you get the Windows warning about BruControl inside the warning box in smaller letters is the word (more) or learn more. Click on that and a new box will open and give you the option to run anyway. Tom

Did the first suggestion with no success, and at the moment I don't have another cable. Going to order one today.try plugging the arduino into a different computer and changing the cable

Well after several hours of playing I finally got the brucontrol firmware installed. I was double clicking the button before but in the end the problem was the Adafruit drivers. The latest installer posted (v2.3.1) did not install the Feather drivers. After installing an old version (v2.0) everything went smoothly. Upon digging around the actual drivers, I found that for some reason the driver signatures were not present on the latest release which is why it was not installed. Seems like others on the web have had a similar experience as well.

so right click and install from administrator doesn't work?

That driver won't work for Arduino MEGA. They are for Adafruit devices, which have a different USB interface chip.

I install unsigned drivers on windows 10 at work at customers sites from time to time for the printing equipment I install and service.... I dont recall the exact steps but when the install fails it prompts you with an option to run it in compatibility mode and that always works... Ive never done what you mentioned here before. but thats with an actual driver installer program...No, that would work with Windows XP, 7, and 8 but not 10. The reason for this is now every driver has to signed-off by Microsoft (hence the name signature) to ensure safety and compatibility which, in theory is a great idea. However, its left to the individual manufacturers to send in their drivers which many don't do in a timely manner. While, one can install unsigned drivers I wouldn't recommend it unless you know what your doing since you have to "unlock" your computer which could cause major issues with other programs.

@TexasWine best of luck here is the direct link to the drivers I installed for you and others should the one you downloaded not work (I had to try progressively older versions till I found one that worked)

https://github.com/adafruit/Adafruit_Windows_Drivers/releases/download/1.1/adafruit_drivers.exe

I had read the PDF, the interface guidelines, etc... I knew nothing about the double button push...

Will the scripting gods look at this and help me find my errors?

That script is very long for someone to decode offline. Posting just the hiccup parts might help. One quick thing noted... section names must be unique. You can’t have multiple sections named [timer], since the script interpreter won’t know which one to go to.

Going way back for this one. Any issues threading the NPS on this meter to NPT elsewhere in your system?I almost hate to admit it... but this guy: https://www.adafruit.com/product/828

You can get this model in ebay easily also. Best $10 bucks I have ever spent! The thing has been through a bunch of brews and subsequent cleanings with PBW, yet keeps ticking! It's not crazy accurate, but it is repeatable once calibrated!

While on the topic, here is how you do it in BruControl. I measured the number of pulses it puts out when a quart flows through it, which is about 355. For total flow, you therefore enter 1/355 = 0.0028169 as a Linear Multiplier calibration for the Counter's Total value to get the total in quarts. For the rate (which outputs rate per second), you enter 60/355 = 0.169014 to get quarts per minute (since there are 60 seconds in a minute).

View attachment 397355

Enter your email address to join: