I had a look on my workspaces and moved things around to see if it is hiding behind another element but no luck . I've sent my "Config File" to you, I can see it in the config file but not sure if it's as simple as editing the file to remove it and implementing the file as a new entry in the file log?

This is a regular problem that I had. I have renamed every Element I have that includes the Workspace in the name.

I use the following for an Device Element Name.

1-3= Interface

MB_ = Main Brewery Mega Unishield

ES_ = ESP32

GC_ = Grand Central Unishield

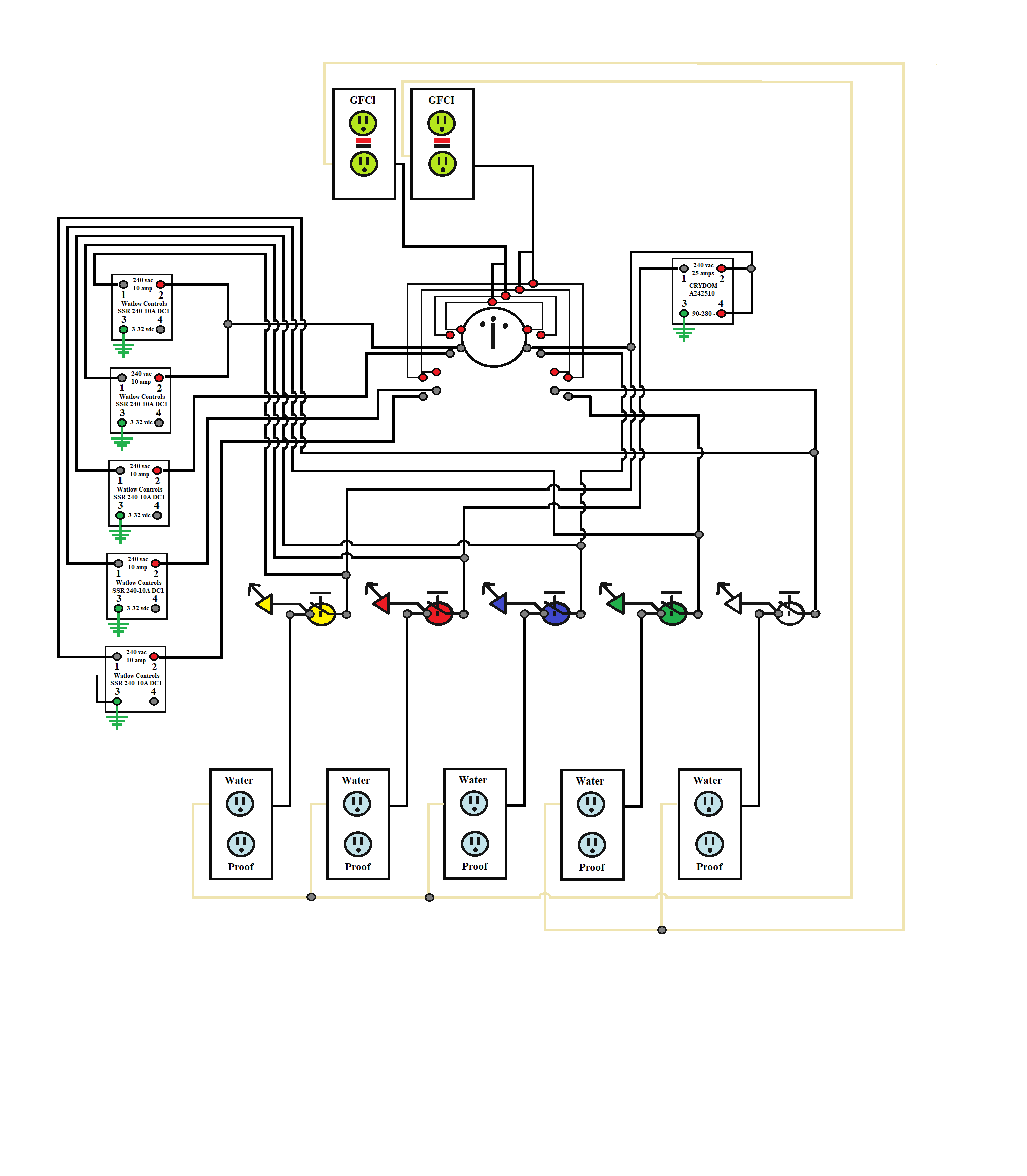

NW_ = Not Wired Mega ( I use this to create pseudo Elements that are not wired off the interface, but use scripting to manipulate a real Element. I have five pumps and needed to control on different Workspaces, so I have both a real Yellow pump and a Pseudo Yellow Pump on different Workspace. I do this so the Elements look and act exactly the same on both Workspaces. Since a Mega 2560 is cheap, it was an easy decision. I also use Pseudo Elements to control some real Elements on the same workspace.

3-6 = Port/Pin

22_ = Port/Pin 22

7-10 = type

DB__ = Dead Band

di__ =Direct Input

DO__ = Direct Output

DCO_ Duty Cycle Output

HYS_ = Hysteresis

PID = Pid

rtd_ = SPI Input (RTD Temp Probe)

10K_ = Analog 10K Temp Probe

1wr_ = One Wire Temp Probe

fmA_ = Flow Meter Analog Input

fmH = Counter (Hall Effect Flow Meter)

and others if I need them

11- as needed

What it is

example: BrewKettleBurner_

Last 2 = Workspace

B1 = Main Brew Page

WT = water

FM = Fermenter Workspace

ALARM = Alarm Work Space

2B = Second Batch

and as needed.

As a specific example my Brew Kettle Burner (a solenoid gas valve that is a direct output) is on Port 22 of my Mega Uni Interface:

MB_22_do__BrewKettleBurner_B1

I then use the display name of Brew Kettle Burner.

The name has to be unique as you can only have one direct output on Port/Pin 22 of a single interface Interface and somewhat meaningless from a computer language view, but tells you a lot about it.

Application Elements are sorta the same:

tm_ = timer

alm_ = alarm

gblS = String Global Variable

gllV_ = Value Global Variable

gblT_ = Time Global Variable

gblB_ = Boolean Global Variable

gblDT_ = Date Time Global Variable

graph_ = graph

sw_ = switch

btn_ = button

inspect = inspector ( I do not use these as I find global do very well for this)

example: alm_FlavorHops1_ALARM

I try not to stack Elements so I that I cannot see them. I use the hiddenlocked attribute and never use the hidden attribute in scripting.

You could come up with your own system to make the names unique and tell you something about them at the same time. It was a pain to go back and change all references to a name when I changed it as I did not start to do this initially, but I finally figured out how to do it easily in Notepad++) After I changed my Element Names, I have had an easier time finding the

(As an aside, I could have a single Alarm Element that I could use for everything if I could change the

path of Image 1 and File one, or at least one per Workspace! Personally, I could use just one for everything!!!)

I did lose one Device Element (a counter) that I have never found. It was early on in my setting up Brucontrol but I do not need it so no big deal as I changed my mind about installing Hall Effect flow meters.

It would be nice to have a screen print out of all your devices and what worksheet they were assigned to.