Definitely!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BruControl: Brewery control & automation software

- Thread starter BrunDog

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

yup... industrial automation uses 100A and more... I run 100A, but switch it in 50A because contactors are cheaper...

google is your friend... here is one on eBay

google is your friend... here is one on eBay

I’m curious... what do you mean you “switch it at 50”? Are you using 2 50A contactors to switch 100A?

I use 2 50A contactors, each on 50A circuits, to switch 2x 22.8A elements each... so not sharing the dangerous way, which would be re-connecting after the contactor..

I am starting to change the wiring over from the BCS for the 10K NTC probes. On the TF-3 there are two connectors for RT 1, RT2, RT3, RT5 and RT6. In my diagram I am showing RT3. Since I have my wiring on the old BCS where there is a common ground for one of the wires running to the Probe, is it possible to put one of the RT Connectors to that common ground or do I need to rewire each probe so it has an independent home run ground to the TF-3? If I can use a common ground, does it mater which connector I use.

The only ground on the TF-3 is the board ground.

Your thermistors must be wired in pairs.

Your thermistors must be wired in pairs.

So I need to home run the two wires from the probe to the TF-3. I assume there is no polarity. I will do that.

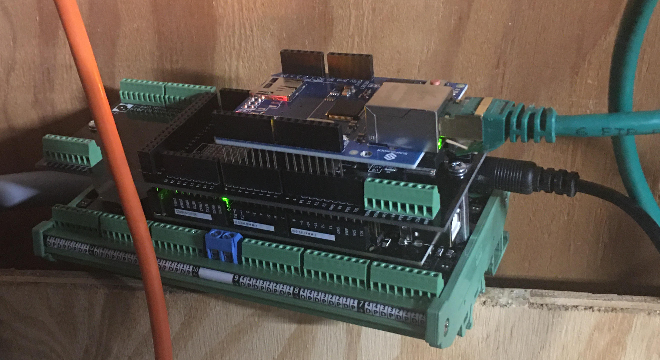

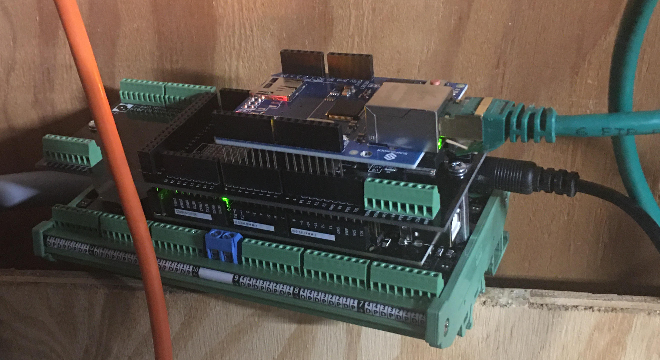

Wahoo! Added an Ethernet Board to my UM-1 board and it fit nicely. No nightmare. I am going to add a lot of valves with this baby!

I have a 5vdc 3amp transformer (Meanwell 20-5) that I intend to power items that need the 5 vdc. With the UM-1 board, it looks like that would be a good candidate to power with the transformer and also have the AREF to VCC Dip Switch On. Am I reading this correctly?

Yes. Combining signals is not a good idea

Yessir... by design!Wahoo! Added an Ethernet Board to my UM-1 board and it fit nicely. No nightmare. I am going to add a lot of valves with this baby!

View attachment 664844

I have a 5vdc 3amp transformer (Meanwell 20-5) that I intend to power items that need the 5 vdc. With the UM-1 board, it looks like that would be a good candidate to power with the transformer and also have the AREF to VCC Dip Switch On. Am I reading this correctly?

I would keep the AREF switch to VCC on. Just make sure your external power supply is 5.00V. You could turn that switch off and wire your external power supply to AREF... it won't really matter as it won't read higher than 5V anyway.

Also, I suggest you power the UM-1 via the VS terminal. Let the on-board power supply do the work.

@BrunDog, there is something weird with PID on the Mega. Just changed my temp sensor, SSR output and PID from a Feather to a Mega (45E) and its behaving strange, and not as it did on the Feather. For example direct mode, Kp=1, Ki=0, Kd=0, temp 15, target 0 gives output 255. Changed Kp to 0.01 and then output is 27 at target=0. The output should be zero as long as its proportional only and PV is above setpoint?

Do you have reversed turned on?

Otherwise you might turn on debug level 2 for a peek at the components.

We’ll test this and report back. What type sensor are you using?

Otherwise you might turn on debug level 2 for a peek at the components.

We’ll test this and report back. What type sensor are you using?

augiedoggy

Well-Known Member

I use 2 60a contactors to switch and keep the 2 60a circuits in my 3bbl panels separate. I do not reconnect the 2 circuits anywhere in the panel as they are fed from 2 60a gfci breakers in the main power panel.I use 2 50A contactors, each on 50A circuits, to switch 2x 22.8A elements each... so not sharing the dangerous way, which would be re-connecting after the contactor..

aeviaanah

Well-Known Member

- Joined

- Jul 1, 2012

- Messages

- 1,686

- Reaction score

- 217

I use 2 60a contactors to switch and keep the 2 60a circuits in my 3bbl panels separate. I do not reconnect the 2 circuits anywhere in the panel as they are fed from 2 60a gfci breakers in the main power panel.

What pumps do you run on the hot side?

My screen resolution changes when I have an external monitor hooked up vs the native laptop. I have the resolution set on the Laptop to the highest setting, but I get more screen real estate with an external monitor. I like the bigger screen. The issue is that if I do not have the external monitor up, some of the on screen Elements move by them selves in some cases. I find it happens often if I open the Script window. It would be nice to have a position lock property for an element.

- Joined

- Mar 24, 2016

- Messages

- 551

- Reaction score

- 60

My screen resolution changes when I have an external monitor hooked up vs the native laptop. I have the resolution set on the Laptop to the highest setting, but I get more screen real estate with an external monitor. I like the bigger screen. The issue is that if I do not have the external monitor up, some of the on screen Elements move by them selves in some cases. I find it happens often if I open the Script window. It would be nice to have a position lock property for an element.

What about doing the opposite? Try setting the external monitors resolution to match the laptop. Do they both offer the same resolution settings? Maybe pick one that is the same on both.

What about doing the opposite? Try setting the external monitors resolution to match the laptop. Do they both offer the same resolution settings? Maybe pick one that is the same on both.

I like the increased real estate. My screen is about a third wider. Even if I went to the smaller screen ( which I had done), I still have an issue with things moving on there own. I decided the increased real estate was better and re did it again.

Car Ramrod

Well-Known Member

- Joined

- Jan 24, 2019

- Messages

- 117

- Reaction score

- 16

hey @BrunDog are you still selling quadzilla's? how are you wiring the individual wires? are you using quick disconnects? 4 different cables? single cable for all wires? I might be in the market in a few months now i build my basic controller(thread in the electric brewing forum) and will move on to my full automated controller.

I like the increased real estate. My screen is about a third wider. Even if I went to the smaller screen ( which I had done), I still have an issue with things moving on there own. I decided the increased real estate was better and re did it again.

I think that switching screens and resolutions is an uncommon use case. The trade-off is that elements get lost off screen and then the user cannot access them. If one were enabled and needed to be disabled in a hurry, this could create a dangerous situation. So while I appreciate the request, I don’t think we would pursue this change.

hey @BrunDog are you still selling quadzilla's? how are you wiring the individual wires? are you using quick disconnects? 4 different cables? single cable for all wires? I might be in the market in a few months now i build my basic controller(thread in the electric brewing forum) and will move on to my full automated controller.

Yessir. I personally wire all four into one 30A connector, but you could wire them separately if you wanted to divide up the power. Each heater is about 1200W at 240VAC, so you could run one heater in the RIMs while simultaneously heating your HLT or BK and a pump and technically stay at/under 30A.

Alternatively, wire two heaters to Line 1 / Neutral and the other two to Line 2 / Neutral, to balance the load and run the total heater at 120V for super ultra low density. I actually would just run it at 240V and keep the duty cycle correct, but lots of choices if you want to do something interesting.

Of course you need the controls to switch more element legs, so that could mean more SSR’s, breakers, etc.

- Joined

- Mar 24, 2016

- Messages

- 551

- Reaction score

- 60

I apologize if this isn’t the right place for this post. I’m trying to send a Brewfather recipe via Brewfather json export to node red and then to Brucontrol. Brewfather will let me send the json recipe to a custom endpoint but I need to setup one first. This is where I need help. Thanks.

Set up a "http in" node, chose method "POST" and in url you set the address for example /brewfather. The endpoint address is now http://yournoderedipaddress:1880/brewfather. Then you can test it by using the postman app. Brewfather only supports https endpoints so next is to make your node red installation https. I am using nginx and letsencrypt but it should be possible to make it https from the config file.

Edit: you must enable CORS also, i think its done in the config file

Edit: you must enable CORS also, i think its done in the config file

Car Ramrod

Well-Known Member

- Joined

- Jan 24, 2019

- Messages

- 117

- Reaction score

- 16

Right so with you just wiring them all together, you are just utilizing the ULWD of the element. And not using thing ability to fire all 4 for heating strike water, and then switching to 1 for mash temp stability.Yessir. I personally wire all four into one 30A connector, but you could wire them separately if you wanted to divide up the power. Each heater is about 1200W at 240VAC, so you could run one heater in the RIMs while simultaneously heating your HLT or BK and a pump and technically stay at/under 30A.

Alternatively, wire two heaters to Line 1 / Neutral and the other two to Line 2 / Neutral, to balance the load and run the total heater at 120V for super ultra low density. I actually would just run it at 240V and keep the duty cycle correct, but lots of choices if you want to do something interesting.

Of course you need the controls to switch more element legs, so that could mean more SSR’s, breakers, etc.

Ill probably end up ordering one at some point.

Right. In my personal rig, they run at 240VAC for strike heating, mashout, fly sparging, and cleaning. They run at 120VAC for Mash temp control.

That said, with appropriate controls... say, limiting power to 25% max and maintaining a fairly fast duty cycle, these could easily run at 240VAC full time give their thermal mass and very low density.

I also personally heat strike water on the fly with these, and they do a great job limiting local boiling at 1 qt/min. It's definitely not a cheap element compared to off the shelf stuff, but it is purpose designed for the task. I think if more people adopted tech like this, HERMs could suffer the fate I feel it deserves! No offense HERMs lovers - just my opinion!

That said, with appropriate controls... say, limiting power to 25% max and maintaining a fairly fast duty cycle, these could easily run at 240VAC full time give their thermal mass and very low density.

I also personally heat strike water on the fly with these, and they do a great job limiting local boiling at 1 qt/min. It's definitely not a cheap element compared to off the shelf stuff, but it is purpose designed for the task. I think if more people adopted tech like this, HERMs could suffer the fate I feel it deserves! No offense HERMs lovers - just my opinion!

Car Ramrod

Well-Known Member

- Joined

- Jan 24, 2019

- Messages

- 117

- Reaction score

- 16

Oh i understand. And i have read your HERMS discussion and i tend to agree. At the stage im in, im trying to figure out if i could just tune a manual valve on my RIMS output to limit flow to a certain temp. I have read you use flowmeters and proportional valves and i will go to that at some point but i want to get this implemented as fast as possible. so i can brew with it while i piece together my automated panel.

The flowmeter is nice to have. In all truth, its a bit unnecessary, as a proportional valve can be set to an empiric opening with pretty good repeatability.

But this whole thing is technically unnecessary, amirite?

But this whole thing is technically unnecessary, amirite?

Paulaner

Well-Known Member

Right. In my personal rig, they run at 240VAC for strike heating, mashout, fly sparging, and cleaning. They run at 120VAC for Mash temp control.

That said, with appropriate controls... say, limiting power to 25% max and maintaining a fairly fast duty cycle, these could easily run at 240VAC full time give their thermal mass and very low density.

I also personally heat strike water on the fly with these, and they do a great job limiting local boiling at 1 qt/min. It's definitely not a cheap element compared to off the shelf stuff, but it is purpose designed for the task. I think if more people adopted tech like this, HERMs could suffer the fate I feel it deserves! No offense HERMs lovers - just my opinion!

I’m looking forward getting my quadzilla up and running to see the performance of these. I’m banking on these performing as good as you have talked about previously, or else I’m gonna have to convert my new system over to a HERMS setup. We’ll see if we can give Bryan a run for his money on a RIMS setup.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

I’m looking forward getting my quadzilla up and running to see the performance of these. I’m banking on these performing as good as you have talked about previously, or else I’m gonna have to convert my new system over to a HERMS setup. We’ll see if we can give Bryan a run for his money on a RIMS setup.

If there is anyone I trust to test it, it's you. I think back to my BIAB testing (braumeisters) and having a direct element going while mashing, I did not like the thermal stress or the flavors associated with it.

Paulaner

Well-Known Member

That's my biggest worry, I know you've mentioned this before and I would agree with you on the noted flavor difference.If there is anyone I trust to test it, it's you. I think back to my BIAB testing (braumeisters) and having a direct element going while mashing, I did not like the thermal stress or the flavors associated with it.

aeviaanah

Well-Known Member

- Joined

- Jul 1, 2012

- Messages

- 1,686

- Reaction score

- 217

I am planning my commercial BC panel. Ill be running (3) 12-18kw 3phase elements in HLT and (3) in kettle.

Discussing just one of these vessels- My first thought was to have a single Arduino output signal branch into (3) control circuits through manual switches, each line to relay board controlling 50amp contactors. This would allow BC to control all elements with a single PID but would rely more on user interaction (to disable/enable the switches) for total power requirements.

My second thought was to have three separate outputs to each relay, I would incorporate multiple PID's or could be script based utilizing a separate control circuit to each element. I could also incorporate the manual switches in this scenario.

Those who have been down this road, which do you suggest? Is there a third option?

Discussing just one of these vessels- My first thought was to have a single Arduino output signal branch into (3) control circuits through manual switches, each line to relay board controlling 50amp contactors. This would allow BC to control all elements with a single PID but would rely more on user interaction (to disable/enable the switches) for total power requirements.

My second thought was to have three separate outputs to each relay, I would incorporate multiple PID's or could be script based utilizing a separate control circuit to each element. I could also incorporate the manual switches in this scenario.

Those who have been down this road, which do you suggest? Is there a third option?

I use a modified Herms/Rims. I have a counterflow chiller (convolutus) that I send hot water through the external loop and the wort down the internal. Takes two pumps but very good mash control. The Quadzilla would work great for this as well (and likely better than what I have).That's my biggest worry, I know you've mentioned this before and I would agree with you on the noted flavor difference.

I am planning my commercial BC panel. Ill be running (3) 12-18kw 3phase elements in HLT and (3) in kettle.

Discussing just one of these vessels- My first thought was to have a single Arduino output signal branch into (3) control circuits through manual switches, each line to relay board controlling 50amp contactors. This would allow BC to control all elements with a single PID but would rely more on user interaction (to disable/enable the switches) for total power requirements.

My second thought was to have three separate outputs to each relay, I would incorporate multiple PID's or could be script based utilizing a separate control circuit to each element. I could also incorporate the manual switches in this scenario.

Those who have been down this road, which do you suggest? Is there a third option?

You could do the first but use 3 on/off outputs from the arduino in addition to the PID outptut to replace the manual switches with relays if you want it to be fully automated. This would eliminate the need for synchronizing multiple outputs to one PID or using multiple PIDs.

aeviaanah

Well-Known Member

- Joined

- Jul 1, 2012

- Messages

- 1,686

- Reaction score

- 217

You could do the first but use 3 on/off outputs from the arduino in addition to the PID outptut to replace the manual switches with relays if you want it to be fully automated. This would eliminate the need for synchronizing multiple outputs to one PID or using multiple PIDs.

Great point. Thank you for the advice

aeviaanah

Well-Known Member

- Joined

- Jul 1, 2012

- Messages

- 1,686

- Reaction score

- 217

You could do the first but use 3 on/off outputs from the arduino in addition to the PID outptut to replace the manual switches with relays if you want it to be fully automated. This would eliminate the need for synchronizing multiple outputs to one PID or using multiple PIDs.

I’m trying to think through this recommendation. Assuming the boil has the biggest benefit for automation here. Are you saying something like this could exist under this recommendation?

Please disregard proper syntax- I’ll correct in due time.

If BoilPID output = true

If BoilTemp >= 208

Switch 1 = true

Switch 2 = false

Switch 3 = false

Endif

Endif

I’m trying to think through this recommendation. Assuming the boil has the biggest benefit for automation here. Are you saying something like this could exist under this recommendation?

Please disregard proper syntax- I’ll correct in due time.

If BoilPID output = true

If BoilTemp >= 208

Switch 1 = true

Switch 2 = false

Switch 3 = false

Endif

Endif

I'm not exactly sure what you are trying to accomplish with that code. However, I would create 3 digital outputs and connect these to the input header on a relay board like this:

https://www.amazon.com/JBtek-Channe...eywords=4+channel+relay&qid=1581091145&sr=8-3

Then take the one PID output from the arduino and branch that out to the common terminal on 3 of the relays. Take the NO output from these 3 relays and feed that to the input of your high voltage/power SSR/relays that you are using to switch the 3 different heating elements. Then you turn the 3 different outputs on/off depending on how much power you want at that time.

This implementation may be overkill. In reality, you may find that hooking 2 elements up to just be on/off and the third to be set for PID might work well. When heating you would have all 3 on all the time, until you reached your target or an offset below the target. Then you could switch to only having one element on and in PID mode to maintain temperature. As long as you can maintain temperature with one element then this would probably be the easiest implementation and would eliminate the need for the 4 channel relay board above.

I am planning my commercial BC panel. Ill be running (3) 12-18kw 3phase elements in HLT and (3) in kettle.

Discussing just one of these vessels- My first thought was to have a single Arduino output signal branch into (3) control circuits through manual switches, each line to relay board controlling 50amp contactors. This would allow BC to control all elements with a single PID but would rely more on user interaction (to disable/enable the switches) for total power requirements.

My second thought was to have three separate outputs to each relay, I would incorporate multiple PID's or could be script based utilizing a separate control circuit to each element. I could also incorporate the manual switches in this scenario.

Those who have been down this road, which do you suggest? Is there a third option?

I have 5(soon to be 6) 9kw dernord 2" Tri-Clamp 3-phase heating elements, and run them in 2 pairs and a single... I am doing distilling, not boil-kettle, but it is still boiling, so I have them cycle down at temps, bot the liquid and the vapor temp above (and it is a Bain-marie kettle, not direct element, so I monitor the boiler jacket temp and pressure also)

coming from BCS, I ran it like that, with different 'states', and exit conditions for the state, and a variable displaying the 'state' name on the screen...

JoeyChestnutFan

Well-Known Member

- Joined

- Feb 1, 2014

- Messages

- 132

- Reaction score

- 21

If there is anyone I trust to test it, it's you. I think back to my BIAB testing (braumeisters) and having a direct element going while mashing, I did not like the thermal stress or the flavors associated with it.

Interesting... I am not familiar with the braumeister, but I am guessing its recirc and similar to other recirc biab. I wonder if the faster liquid turnover past the element on a RIMS setup with a boil coil watt density (25? i think) would have this same fate. There is a lot of "stale" space around a heating element in a biab setup.

aeviaanah

Well-Known Member

- Joined

- Jul 1, 2012

- Messages

- 1,686

- Reaction score

- 217

Thankyou for the help. Ill sketch this out and think through whether implementation if overkill or not.I'm not exactly sure what you are trying to accomplish with that code. However, I would create 3 digital outputs and connect these to the input header on a relay board like this:

https://www.amazon.com/JBtek-Channe...eywords=4+channel+relay&qid=1581091145&sr=8-3

Then take the one PID output from the arduino and branch that out to the common terminal on 3 of the relays. Take the NO output from these 3 relays and feed that to the input of your high voltage/power SSR/relays that you are using to switch the 3 different heating elements. Then you turn the 3 different outputs on/off depending on how much power you want at that time.

This implementation may be overkill. In reality, you may find that hooking 2 elements up to just be on/off and the third to be set for PID might work well. When heating you would have all 3 on all the time, until you reached your target or an offset below the target. Then you could switch to only having one element on and in PID mode to maintain temperature. As long as you can maintain temperature with one element then this would probably be the easiest implementation and would eliminate the need for the 4 channel relay board above.

My only concern is, can the Arduino handle the draw from the three 50amp contactor coils? This is from the PID branching to the common terminal on 3 of the relays.

SC-E2SG-24VDC

https://cdn.automationdirect.com/static/specs/fujimc9150.pdf

May I ask why so many elements instead of a 12 or 18kw element?I have 5(soon to be 6) 9kw dernord 2" Tri-Clamp 3-phase heating elements, and run them in 2 pairs and a single... I am doing distilling, not boil-kettle, but it is still boiling, so I have them cycle down at temps, bot the liquid and the vapor temp above (and it is a Bain-marie kettle, not direct element, so I monitor the boiler jacket temp and pressure also)

coming from BCS, I ran it like that, with different 'states', and exit conditions for the state, and a variable displaying the 'state' name on the screen...

Last edited:

Similar threads

- Replies

- 29

- Views

- 6K

- Replies

- 51

- Views

- 8K