I had a nice long post written with the app on my phone. I should have learned my lesson the first time the app wouldn't let me post something... grrr.. Let's see if I can remember everything I had written.

Got my new rig in the mail last Friday. Haven't had the opportunity to brew with it yet, but thought I'd relay my first impressions.

The rig comes partially assembled with the elements installed. I had to install the valve, the return tee and temp probe, and wire up the cords to the elements. This was all pretty easy given the provided assembly instructions.

Kettle: The kettle is a 36 quart Bayou Classic with a steamer basket. I already own one of these and have been very happy with it. Given the placement of the outlet valve, there is exactly 0.5 gallons of dead space in the bottom of the kettle. I'm usually a dump-everything-in-the-fermenter kind of guy. We'll see if I resist the temptation to just tip it over and pour that last little bit in the fermenter.

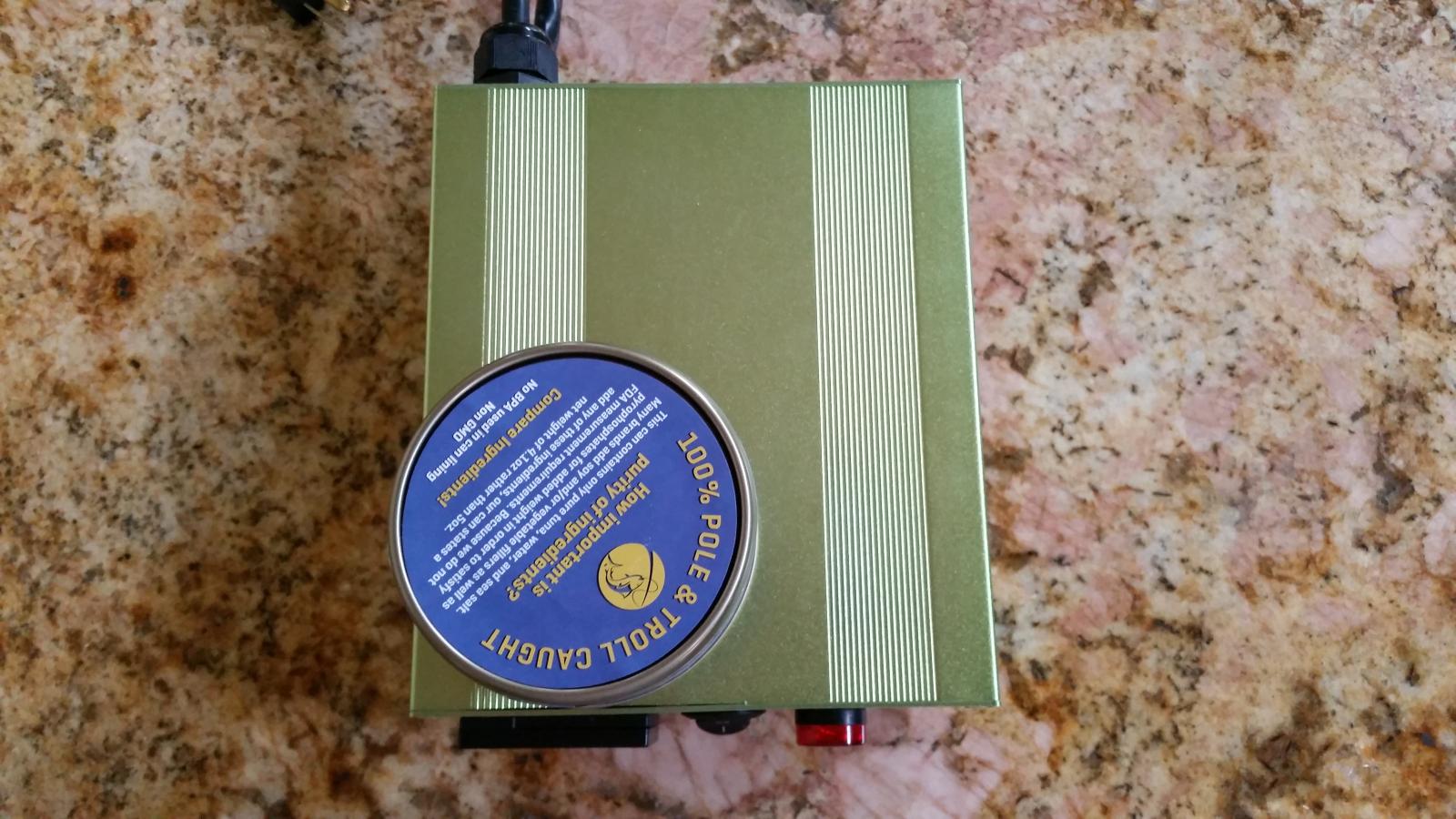

Controller: The controller is housed in a sturdy and compact metal enclosure and is a really nice shade of green. If I'm not mistaken, the wiring to the elements is 16 gauge, which should be sufficient for 1500 watts. Steven even includes detailed instructions on how to set up the controller and perform an auto-tune for your system.

Bag: I've gotta be honest, I was a little skeptical of the BIAB bag included with the rig because of my excellent experience with wilserbrewer's wares. But, as it turns out, it actually looks OK. Steven also included a small hop bag which I put to use this week for dry hopping.

Pump: The pump is a tiny little thing, but it looks like it has a pretty significant flow rate when I pumped some water around in a circle. Maybe I'll measure the flow one day if I'm bored. The small footprint of the pump is going to be appreciated on brew day. One thing that I think would be really nice is an on/off switch in the pumps cord. With the current set up, as soon as you plug the pump in it starts running, so you better be ready and have everything lined up before doing so.

Quick Disconnects: This has been the only snag. The QDs are of sound build, but when I put everything together and was prepped for a wet run, I noticed the quick disconnects were leaking like crazy! I contacted Steven and he was quick to reply. Turns out they got some faulty o-rings from one of their suppliers and he said he'd be happy to ship me some replacements. In the meantime I've ordered some from Amazon. The unfortunate thing is I had to buy a lifetime supply of 100. I hope they fit!

Valve: Appears to be a standard 1/4 turn ball valve. Nothing fancy but suits my needs just fine.

Other thoughts: I kind of wished the kettle was a 40 or 44 quart to allow for bigger batches using the no-sparge technique. With the set up I'll be limited to a grain bill of about 9 pounds doing a no-sparge. But then again, I'm thinking about switching to smaller batches any way to allow me to brew more often. Also, I'm curious how I'm going to control the pump's flow rate without a valve on the discharge. In my line of work we almost always use control valves to keep centrifugal pumps from running out on their curves. In this set up, I can see a discharge valve being handy if, for instance, the wort does not flow through the bag fast enough to keep a steady flow to the pump's suction. Being able to slow down the flow would correct that problem. Then again, I'm just hypothesizing and don't know that it will be a problem to begin with.

That's it for now. Below are a few pictures. Can o'tuna for scale in some pictures.