You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

As they say: another BRUTUS is born!

- Thread starter jcaudill

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

jcaudill

Well-Known Member

So the reality is I could probably write a novel since my last post! Let me start with a few more recent pics:

photo by brewerJP

photo by brewerJP

brew3 by brewerJP, on Flickr

brew2 by brewerJP, on Flickr

photo by brewerJP, on Flickr

photo by brewerJP, on Flickr

photo 1 by brewerJP, on Flickr

photo 1 by brewerJP, on Flickr

Untitled by brewerJP, on Flickr

... continued on next post

photo by brewerJP

photo by brewerJP

brew3 by brewerJP, on Flickr

brew2 by brewerJP, on Flickr

photo by brewerJP, on Flickr

photo by brewerJP, on Flickr

photo 1 by brewerJP, on Flickr

photo 1 by brewerJP, on Flickr

Untitled by brewerJP, on Flickr

... continued on next post

jcaudill

Well-Known Member

I am three brews deep now. The first brew was every bit of the pickling brew I was hoping it wouldn't be. I learned a lot of lessons including:

- Enlarging the gap on the Barley Crusher - the grist was way too fine and kept clogging my recirc - mainly from the influence of the grain bed pressure. Also tossing in rice hulls helps.

- My water/grain ratio was was too low - so I've adjusted that up to a minimum of 1.5qts/lb.

- Use lots of thermal paste in the wells! My variance was pretty high. I'm down to about 2.5-3 degrees now.

- The 110v solenoids worked great - but when my pilots kept going out in the wind I had gas pouring out. I brew outside so that's not the end of the world - but it did make me feel pretty uncomfortable.

- Fermentation was a disaster. I was trying to make a lager - and I thought I could somewhat manage temps using a bucket of cold water from the keezer running through the Brewhemoth's immersion chiller. I was wrong. I couldn't get it much below 65. Pretty much dampf bier!

So I made adjustments for the re-brew. Some I described above already (such as the water/grain ratio, the mill gap, the rice hulls). But I also did the following:

- Converted over to Honeywell VR8200a gas controls. Had to add a 24v transformer to the panel for those.

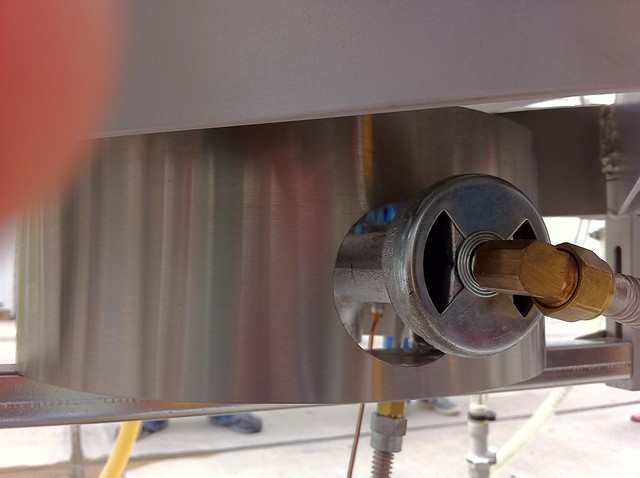

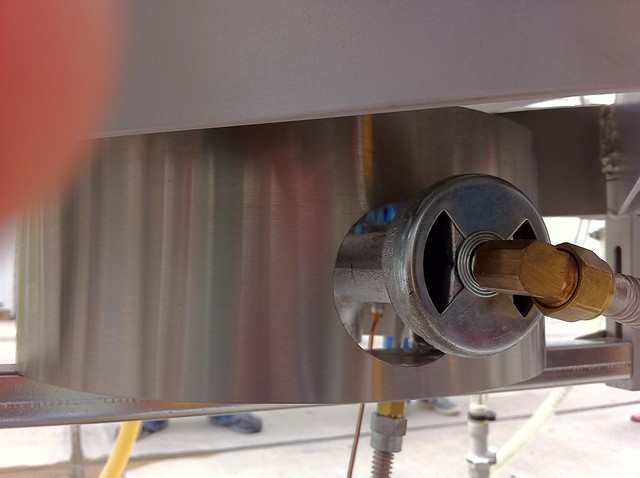

- Built stainless wind screens for the burners to help keep my pilots lit!

- Bought a dedicated glycol power pack for the immersion chiller.

All these combined I ended up with a great second brew. The day went smooth, and the fermentation even smoother. The glycol power pack was the best money ever spent. Only downside is the ambient temperature in my garage goes up at least 5 degrees when that thing is running! But I have no issue getting down into the 40's now and honestly I could go a lot lower if I wanted.

The only problem I had, and still have, is with burner output. The addition of the Honeywell controls really substantially reduced output. I have a much much cleaner flame now - but heat ups can take a while. So I will be drilling out the orifices to get more gas into the burners and I think this will solve the problem. I just haven't got around to it yet.

The brew kettle I just have a simple adjustable regulator to control the flame. I have had no issues getting to a boil with that. I get better output out of that - but it's not quite as clean. I may need to drill that one too. They are after all low pressure burners. But - overall I'm very happy with the decision to use the 6" ring burners. They are very efficient burners and I don't waste a lot of gas. I also have no soot anywhere and I have not had any scorching issues. For up to 15g, I think they are perfectly fine.

I did a third brew on Memorial day - a Koelsch that went smooth as well. Just got it out of the fermenter a few days ago. I'm on break for a bit while I do some traveling but I'll be hitting it hard in August.

I'm sure I'm missing a lot. I haven't even talked about whirlpooling, chilling, aerating, the keezer, CIP, tubing, yada yada. But as much as anyone wants to know just ask!

Oh one more thing: the ceramic coating is holding up absolutely perfect. I even had my stainless grates ceramic coated. They are holding up too - although they are showing a bit more signs of wear from the direct flame. The coating is rating to 2000 degrees.

- Enlarging the gap on the Barley Crusher - the grist was way too fine and kept clogging my recirc - mainly from the influence of the grain bed pressure. Also tossing in rice hulls helps.

- My water/grain ratio was was too low - so I've adjusted that up to a minimum of 1.5qts/lb.

- Use lots of thermal paste in the wells! My variance was pretty high. I'm down to about 2.5-3 degrees now.

- The 110v solenoids worked great - but when my pilots kept going out in the wind I had gas pouring out. I brew outside so that's not the end of the world - but it did make me feel pretty uncomfortable.

- Fermentation was a disaster. I was trying to make a lager - and I thought I could somewhat manage temps using a bucket of cold water from the keezer running through the Brewhemoth's immersion chiller. I was wrong. I couldn't get it much below 65. Pretty much dampf bier!

So I made adjustments for the re-brew. Some I described above already (such as the water/grain ratio, the mill gap, the rice hulls). But I also did the following:

- Converted over to Honeywell VR8200a gas controls. Had to add a 24v transformer to the panel for those.

- Built stainless wind screens for the burners to help keep my pilots lit!

- Bought a dedicated glycol power pack for the immersion chiller.

All these combined I ended up with a great second brew. The day went smooth, and the fermentation even smoother. The glycol power pack was the best money ever spent. Only downside is the ambient temperature in my garage goes up at least 5 degrees when that thing is running! But I have no issue getting down into the 40's now and honestly I could go a lot lower if I wanted.

The only problem I had, and still have, is with burner output. The addition of the Honeywell controls really substantially reduced output. I have a much much cleaner flame now - but heat ups can take a while. So I will be drilling out the orifices to get more gas into the burners and I think this will solve the problem. I just haven't got around to it yet.

The brew kettle I just have a simple adjustable regulator to control the flame. I have had no issues getting to a boil with that. I get better output out of that - but it's not quite as clean. I may need to drill that one too. They are after all low pressure burners. But - overall I'm very happy with the decision to use the 6" ring burners. They are very efficient burners and I don't waste a lot of gas. I also have no soot anywhere and I have not had any scorching issues. For up to 15g, I think they are perfectly fine.

I did a third brew on Memorial day - a Koelsch that went smooth as well. Just got it out of the fermenter a few days ago. I'm on break for a bit while I do some traveling but I'll be hitting it hard in August.

I'm sure I'm missing a lot. I haven't even talked about whirlpooling, chilling, aerating, the keezer, CIP, tubing, yada yada. But as much as anyone wants to know just ask!

Oh one more thing: the ceramic coating is holding up absolutely perfect. I even had my stainless grates ceramic coated. They are holding up too - although they are showing a bit more signs of wear from the direct flame. The coating is rating to 2000 degrees.

mkirkland

Well-Known Member

No recent updates?

jcaudill

Well-Known Member

Hah, well actually quite a bit has changed since this initial posting. But I have been so focused on working out kinks and brewing that I've neglected updating the thread. So give me a little time and I will post an update!

jcaudill

Well-Known Member

I promised an update - so here it is!

Since the original system I've upgraded darn near everything with exception of the pumps, control panel and stand. Boy have a learned a lot. Here are some more recent pictures:

So here a little synopsis of where this beast stands now:

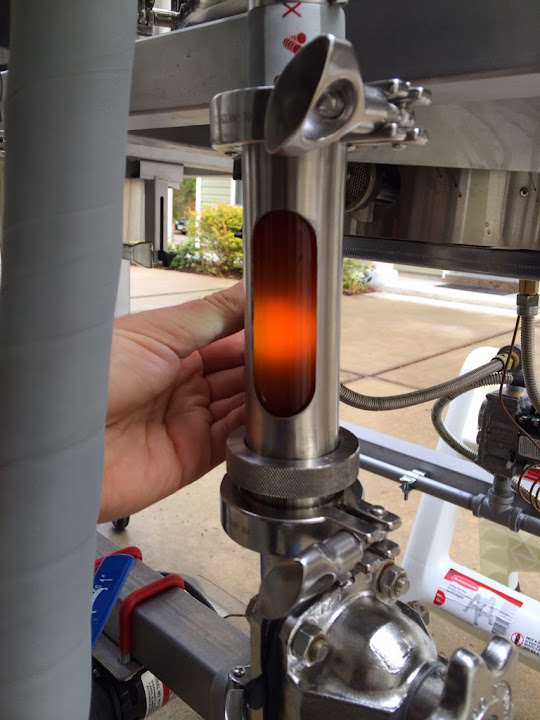

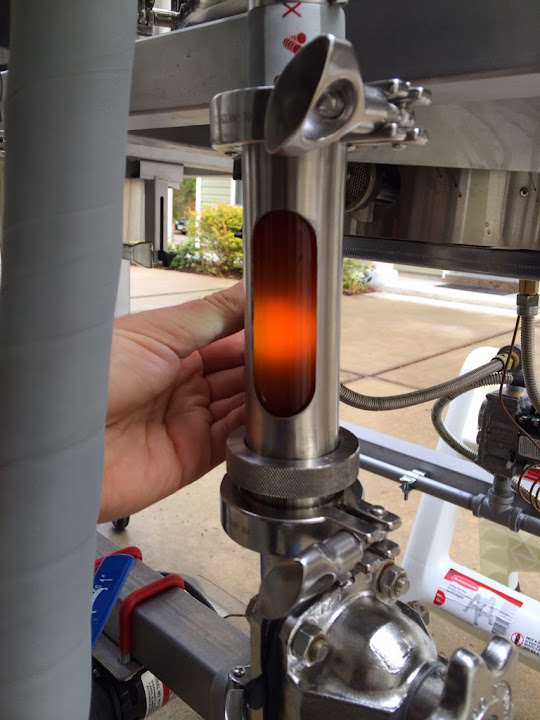

- 3 x 30-gallon Brewer Hardware EC passivated and polished kettles with sanitary ferrules. I had quite a bit of customization to them, including custom sight glasses with returns to the kettle.

- Manifold with 2 x 3-way valves gives some flexibility to move liquid around as I see fit.

- Upgraded all tubing to Novatech 3/4" ID brewer's hose. I got tired of worrying about pressure/temp issues.

- MLT/HLT are controlled by VR8200's now. MLT runs a 6" BG-12 clone, HLT runs a 10" BG-14 clone (both true low pressure) and the BK runs a 4" high pressure cast burner that puts out some serious BTU's. I'm usually at boil in a few minutes as I'm heating up during lautering.

- Upgraded to a 30 plate chiller (yes I went from 50->30 and it is an upgrade). Learning fast 50 is way too big for my incoming flow and it's too hard to clean.

- Still have inline aeration.

- Run 2 Brewhemoths, both controlled from the aforepictured glycol chiller. I built a manifold with two valves and use two controllers for monitoring the fermenters.

- Naturally carbonate through a homemade spunding valve (check my threads and you'll see that project).

- Grain mill gap I've been actually coming back down on. Previous recirc issues were mainly due to pulling too fast. I think I'm down to around .9mm now.

As for dispensing, built a 4-way manifold so I can maintain 4 pressures inside my keezer. This really has helped when I have a weizen and some lower carbonated on.

The last area I'm trying to improve is heat up. I'm building a 55-gallon polypropylene tank with a 4500w element and an Auber PID. Night before the brew I'll filter water in, set mash temp and let it heat up. This saves me about an hour+ of brewday time and lets me have additional water on tap for cleaning without wasting propane.

I'm not sure how many brews I've done but it's been quite a bit. I'm to the point I've about got it figured out and brew days go pretty smooth.

Since the original system I've upgraded darn near everything with exception of the pumps, control panel and stand. Boy have a learned a lot. Here are some more recent pictures:

So here a little synopsis of where this beast stands now:

- 3 x 30-gallon Brewer Hardware EC passivated and polished kettles with sanitary ferrules. I had quite a bit of customization to them, including custom sight glasses with returns to the kettle.

- Manifold with 2 x 3-way valves gives some flexibility to move liquid around as I see fit.

- Upgraded all tubing to Novatech 3/4" ID brewer's hose. I got tired of worrying about pressure/temp issues.

- MLT/HLT are controlled by VR8200's now. MLT runs a 6" BG-12 clone, HLT runs a 10" BG-14 clone (both true low pressure) and the BK runs a 4" high pressure cast burner that puts out some serious BTU's. I'm usually at boil in a few minutes as I'm heating up during lautering.

- Upgraded to a 30 plate chiller (yes I went from 50->30 and it is an upgrade). Learning fast 50 is way too big for my incoming flow and it's too hard to clean.

- Still have inline aeration.

- Run 2 Brewhemoths, both controlled from the aforepictured glycol chiller. I built a manifold with two valves and use two controllers for monitoring the fermenters.

- Naturally carbonate through a homemade spunding valve (check my threads and you'll see that project).

- Grain mill gap I've been actually coming back down on. Previous recirc issues were mainly due to pulling too fast. I think I'm down to around .9mm now.

As for dispensing, built a 4-way manifold so I can maintain 4 pressures inside my keezer. This really has helped when I have a weizen and some lower carbonated on.

The last area I'm trying to improve is heat up. I'm building a 55-gallon polypropylene tank with a 4500w element and an Auber PID. Night before the brew I'll filter water in, set mash temp and let it heat up. This saves me about an hour+ of brewday time and lets me have additional water on tap for cleaning without wasting propane.

I'm not sure how many brews I've done but it's been quite a bit. I'm to the point I've about got it figured out and brew days go pretty smooth.

30Bones

Well-Known Member

Super impressive! I'll try to read through this thread later tonight.

Thanks for all the help on propane. I'm about ready to brew after a vacation and some warmer temps.

Thanks for all the help on propane. I'm about ready to brew after a vacation and some warmer temps.

jcaudill

Well-Known Member

Super impressive! I'll try to read through this thread later tonight.

Thanks for all the help on propane. I'm about ready to brew after a vacation and some warmer temps.

No problem!

What do you mean by 4-way manifold? Do you mean you have separate pressure gauges you can set for each keg?

Just want to make sure I'm not missing out on anything. I have a 4 gang-valve manifold setup, but I'd need to spend $$$ to independently set each keg to a different pressure.

Just want to make sure I'm not missing out on anything. I have a 4 gang-valve manifold setup, but I'd need to spend $$$ to independently set each keg to a different pressure.

jcaudill

Well-Known Member

What do you mean by 4-way manifold? Do you mean you have separate pressure gauges you can set for each keg?

Just want to make sure I'm not missing out on anything. I have a 4 gang-valve manifold setup, but I'd need to spend $$$ to independently set each keg to a different pressure.

Yes I have 4 secondary regulators feeding off a main primary/secondary on the tank and inside the keezer I split the 4 into 8 so I can maintain 4 pressures over 8 kegs. The manifold says outside the freezer so the readings aren't affected by temps.

byrone

Well-Known Member

- Joined

- Jan 25, 2013

- Messages

- 100

- Reaction score

- 5

Awesome rig! You've done an amazing job. A quick question if you don't mind, I've been looking at upgrading my kettles with ones from brewers hardware. Would you mind giving your thoughts on them?

Sent from my iPhone using Home Brew

Sent from my iPhone using Home Brew

jcaudill

Well-Known Member

Awesome rig! You've done an amazing job. A quick question if you don't mind, I've been looking at upgrading my kettles with ones from brewers hardware. Would you mind giving your thoughts on them?

Sent from my iPhone using Home Brew

Thanks!

I love the kettles. I have not had a single issue with them. And Derrin has been great to work with. What I particularly like is he knows what the hell he's doing when it comes to working with stainless! Of course I can't speak to the threaded kettles only the sanitary. Anything you need to know in particular just let me know.