The mash thickness does affect ferementability but it's also highly coupled to temperature. I'd stick with 1.25qt/lb mash thickness and double check your thermometer's accuracy. It seems to me that you're temp is dropping a couple degrees or your thermo is reading a little high. Make sure it reads 212 in boiling water. I also suspect you could be losing temp by opening your cooler to stir. Once you're fully doughed in and confirm temp, don't open the cooler again until it's time to vorlauf.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

All-Grain Tutorial/Nut Brown Ale

- Thread starter DubbelDach

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

givemaboot

Well-Known Member

Thanks for the info and progress report. Let us know how it turns out.

monty3777

Well-Known Member

- Joined

- Aug 13, 2008

- Messages

- 250

- Reaction score

- 2

I'm not sure if I'm using the right lingo - kinda new to this stuff, but I think this thread should be a sticky - I'd hate to loose track of it and it's a great tutorial for newbies like me. It would be great if there were an entire forum filled with these step by step threads. I tell ya - I'm damn near ready to pay for a subscription to this forum!!! Great stuff.

DubbelDach

Well-Known Member

I tell ya - I'm damn near ready to pay for a subscription to this forum!!!

My name is DD and I approve this message. Some of the best money I have spent yet on homebrewing!

I'm glad that this is appreciated. I am going to continue to post every step until I take my first sip of the stuff when it's ready.

Ryan

Well-Known Member

I pitched my yeast later in the evening - my hose water could only get the wort down to 85 degrees - when the beer was cooler. The only pic I forgot to take all day was me hitting the wort with oxygen right before pitching the yeast.

I will continue to give fermentation through bottling updates as they become available. I do want to send a special thank you to Edwort for his Haus Pale Ale recipe. It's in my keg right now and fueled this brew day for me!

Again, The entire gallery of pics can be seen here.

Where did you get that glass with your logo etched into it? It looks awesome!!!

DubbelDach

Well-Known Member

Where did you get that glass with your logo etched into it? It looks awesome!!!

Thanks! Got them here: Esigns4u.com - Etched Glassware - Etched Stainless Cups - Great Gift Ideas!

I got 4 of them and I think they were $8 or $10 each. Did the logo in Illustrator and they reproduced it perfectly. I was worried about the small letters at the bottom of the logo, but they are crystal clear.

No pun.

Kulprit

Well-Known Member

- Joined

- Oct 21, 2007

- Messages

- 109

- Reaction score

- 2

Just wanted to post and say thank you very much.

As an extract brewer it's hard for me to wrap my head around exactly what the difference is between AG and extract.

Seeing a well explained tutorial helps to clarify it and understand it more.

As an extract brewer it's hard for me to wrap my head around exactly what the difference is between AG and extract.

Seeing a well explained tutorial helps to clarify it and understand it more.

Jaysus

Well-Known Member

O

I always use this Mash Calculator for my strike and sparge water. Now, call me crazy, but it always gives a larger volume of water for the sparge, not the strike, so I always reverse them. Makes sense to me to add the larger volume first, where grain absorbtion is higher.

I don't know why I always think that I am smarter than the calculator.... but that just is not the case. Maybe next time, I actually listen to it.

newbrewr4fun

Well-Known Member

how do you decide how much wort to transfer for the first runnings?

Where did you get your thief? This is the first I saw that looks like a graduated cylinderUpdate.... About 72 hours out now, barely a bubble coming through the airlock. I took a sample with my thief, and:

DeadDoc

Well-Known Member

Ooo I love text with pictures makes things sometimes just a little bit easier to understand than just reading it out of a book. I am a very hands on/visual learner.

DubbelDach

Well-Known Member

Some respondings...

Huh? I think you're asking how you determine how much water to add? I use the mash calculator. You tell it how much grain you have and how much wort you want to boil, and it tells you how much water to use. I then drain every last drop that I can get out of my tun and it's usually dead-on accurate.

Funny thing is, I bought a plastic hydrometer after my 4th broken glass one. My original cylinder was too small. Fortunately, my LHBS had this big one. (I needed two hands to thief and dump into the cylinder... so no pic!)

Funny thing is, I bought a plastic hydrometer after my 4th broken glass one. My original cylinder was too small. Fortunately, my LHBS had this big one. (I needed two hands to thief and dump into the cylinder... so no pic!)

As am I... I feel your pain and wanted to help!

Next update will be tonight! I am bottling the brown ale with the wife's help. Pics to come...

how do you decide how much wort to transfer for the first runnings?

Huh? I think you're asking how you determine how much water to add? I use the mash calculator. You tell it how much grain you have and how much wort you want to boil, and it tells you how much water to use. I then drain every last drop that I can get out of my tun and it's usually dead-on accurate.

Where did you get your thief? This is the first I saw that looks like a graduated cylinder

Ooo I love text with pictures makes things sometimes just a little bit easier to understand than just reading it out of a book. I am a very hands on/visual learner.

As am I... I feel your pain and wanted to help!

Next update will be tonight! I am bottling the brown ale with the wife's help. Pics to come...

DeadDoc

Well-Known Member

First running is just the mashed water not sparge water if I'm not mistaken... TO calculate you can use a nifty program or a calculator, as shown in an above reply, or do 1-2qts per pound of grain (1.25-1.5 is the usual unless you know what you are doing by going higher or lower). Different temps of the mash result in different things being done, some of which are not necessary. Sparge water is generally double the amount.

You don't have to do any of the above methods... if u have a method you are using and it is working for you and you are hitting the results you want and the beer is coming out how you like then you don't neeed to change. unless you see room for improvement or just don't care about trying a different way.. haha. It's all about the fun and doing something you enjoy

Edit.

HAHA I love your "brewed in a garage" on your logo.

You don't have to do any of the above methods... if u have a method you are using and it is working for you and you are hitting the results you want and the beer is coming out how you like then you don't neeed to change. unless you see room for improvement or just don't care about trying a different way.. haha. It's all about the fun and doing something you enjoy

Edit.

HAHA I love your "brewed in a garage" on your logo.

DubbelDach

Well-Known Member

Bottling time!

Last night I sanitized 48 bottles in my dishwasher. No soap, no sanitizer, just the 190 degree heat. I have had 0 problems with this method ever since I got the dishwasher a year and a half ago.

Last night I sanitized 48 bottles in my dishwasher. No soap, no sanitizer, just the 190 degree heat. I have had 0 problems with this method ever since I got the dishwasher a year and a half ago.

DubbelDach

Well-Known Member

Soon as my wife is done eating dinner, I am going to boil 3/4 cup of priming sugar for 10 minutes then chill in an ice bath in the sink.

Here I am filling my bottling bucket with sanitizer and soaking my auto siphon and bottling wand. I will fill the container of caps and my spray bottle with the solution in the bucket when I drain.

I prime the siphon with the sanitizer to let it soak. More pics later after we fill 'em up!!!

Here I am filling my bottling bucket with sanitizer and soaking my auto siphon and bottling wand. I will fill the container of caps and my spray bottle with the solution in the bucket when I drain.

I prime the siphon with the sanitizer to let it soak. More pics later after we fill 'em up!!!

DubbelDach

Well-Known Member

OK, so I usually empty my sanitizer in the sink. Then I can lay my siphon and stuff in there while I move other things down ot the garage.

I boil the 3/4 cup priming sugar with a pint of water for 5 mins.

Then cool it just until it's cool enough to touch the bottom of the pan.

I boil the 3/4 cup priming sugar with a pint of water for 5 mins.

Then cool it just until it's cool enough to touch the bottom of the pan.

DubbelDach

Well-Known Member

My bottling line... L to R: Sanitized bottles, beer, bottling bucket, priming sugar, siphon and bottling wand, capper, rinse bucket, and empty cases.

Priming sugar is already dumped into the bucket, so my lovely wife is racking onto it. She supports beer.

I then fill the bottles...

Priming sugar is already dumped into the bucket, so my lovely wife is racking onto it. She supports beer.

I then fill the bottles...

DubbelDach

Well-Known Member

... and she caps them. Note the Troeg's Brewfest shirt because she rocks!!!

Everything is capped and then gets a quick dip in a bucket of warm water. I like to rinse the beer off of them.

And they are cased up and ready to store in the basement at 65-70 degrees for 2-3 weeks.

I got 44 bottles this time... I was a little under 5 gallons, so I got more than I thought, actually. I am going to rig up a dip tube for the back of my bottling bucket valve asap. I leave too much in the bucket.

I have a label design in the works, but I am going to alter it a bit before posting. I used blue caps this time, and the graphic artist in me needs to match. More soon!

Everything is capped and then gets a quick dip in a bucket of warm water. I like to rinse the beer off of them.

And they are cased up and ready to store in the basement at 65-70 degrees for 2-3 weeks.

I got 44 bottles this time... I was a little under 5 gallons, so I got more than I thought, actually. I am going to rig up a dip tube for the back of my bottling bucket valve asap. I leave too much in the bucket.

I have a label design in the works, but I am going to alter it a bit before posting. I used blue caps this time, and the graphic artist in me needs to match. More soon!

portlandbeergeek

Well-Known Member

It's been about four hours.....have you tasted one yet?!???

Or are you more patient than I?

Or are you more patient than I?

DubbelDach

Well-Known Member

I drank the last bit in the bottling bucket and it was real good. I am very excited for this one! My Scottish ale was 2 weeks in the bottle last night, so I chilled and cracked one of those. Still needs another week for a little more carb and ot work out some taste kinks.

Sorry for my slow reply ... looks like a great beer you have there.

Yes, you are correct in that a thinner mash versus a thicker one (ALL other things being equal) should produce a more fermentable wort. From Fix* (via DeClerk): "It has been known that thicker mashes favor proteoletic activity whereas thinner mashes favor carbohydrase action because of the restraining influence [high] sugar concentrations have on alpha and beta amylase activity."

In other terms, if it's too thick, the enzymes will be prohibited from doing a thorough job of breaking sugars down into fermentables.

I would say that mash temperature plays a MUCH larger role in producing a more or less fermentable wort so, if your process is working for you and you are hitting the mash temps you have designed into your recipe (higher = less fermentable) then the thickness is probably of minor concern. It is, however, one more tool in your brewer's toolbox.

Again, great work.

*Fix, George : Principles of Brewing Science (2nd ed) - 1999

Yes, you are correct in that a thinner mash versus a thicker one (ALL other things being equal) should produce a more fermentable wort. From Fix* (via DeClerk): "It has been known that thicker mashes favor proteoletic activity whereas thinner mashes favor carbohydrase action because of the restraining influence [high] sugar concentrations have on alpha and beta amylase activity."

In other terms, if it's too thick, the enzymes will be prohibited from doing a thorough job of breaking sugars down into fermentables.

I would say that mash temperature plays a MUCH larger role in producing a more or less fermentable wort so, if your process is working for you and you are hitting the mash temps you have designed into your recipe (higher = less fermentable) then the thickness is probably of minor concern. It is, however, one more tool in your brewer's toolbox.

Again, great work.

*Fix, George : Principles of Brewing Science (2nd ed) - 1999

chefchris

Well-Known Member

#2

mash

vorlauf and drain

add half sparge amount @ 185F, stir, vorlauf, drain

add second half sparge amount @ 185, stir, vorlauf, drain

3 runnings at progressively higher temps, very high efficiency

I plan on trying this method this weekend.

I have a quick question. How long do you let it sit after adding the sparge water each time. 10 or so minutes then stir?

Also, I'm getting a little confused after reading this whole thread. But once you get your first runnings (using this method) do you start to bring those to a boil?

Thanks, this has been very helpful.

DubbelDach

Well-Known Member

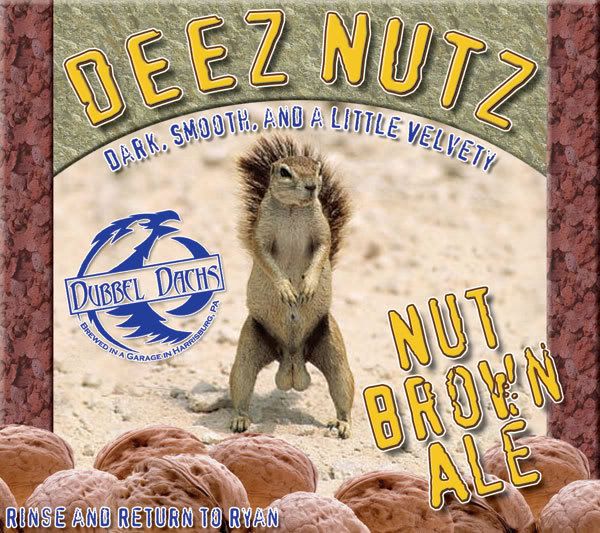

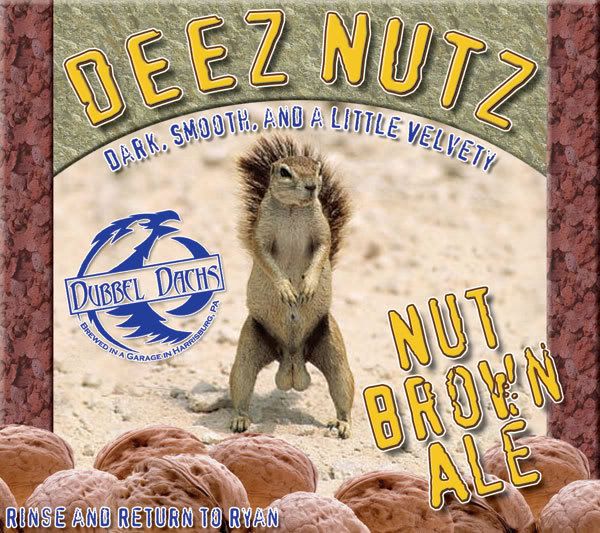

So hey.... Finally got arount to designing a label and fixing it to all the Nut Brown bottles. Yeah, I've been wanting to use the big-nutted internet scuirrel for a long time on a bottle, so I went for it:

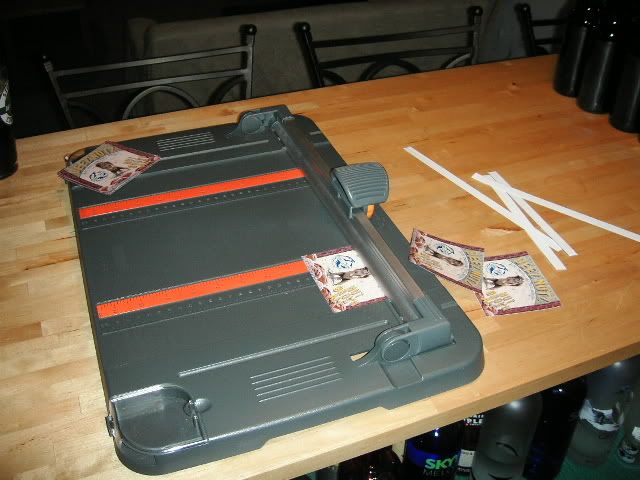

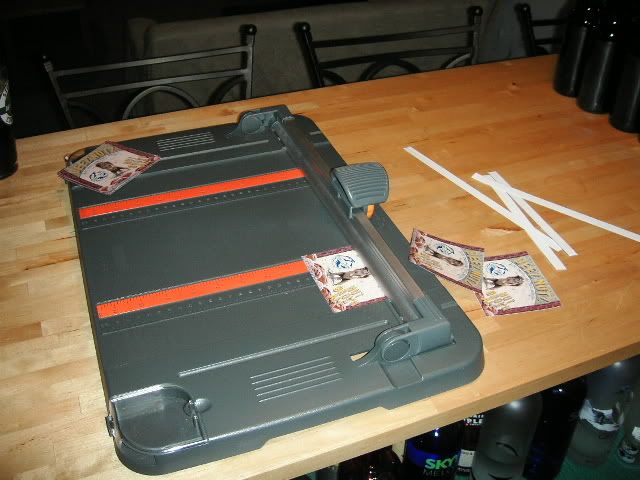

My wife got a paper cutter from a craft store before our wedding for all the design projects I had to do for that... But it's pretty much mine now. I like that it has a rolling blade instead of the big chopping arm:

Nice, straight cuts... I use this paper for the labels. It's gummy on one side, so I just swipe it with a wet paper towel and stick it on. I then spray a clear coat of shellaq on them. They are printed on a Dell 3000CN laser printer (also a wedding prep prize!)

My wife got a paper cutter from a craft store before our wedding for all the design projects I had to do for that... But it's pretty much mine now. I like that it has a rolling blade instead of the big chopping arm:

Nice, straight cuts... I use this paper for the labels. It's gummy on one side, so I just swipe it with a wet paper towel and stick it on. I then spray a clear coat of shellaq on them. They are printed on a Dell 3000CN laser printer (also a wedding prep prize!)

DubbelDach

Well-Known Member

And the final product!

And close-ups...

Special thanks again to Lil' Sparky... The recipe is truly tremendous!!!

And close-ups...

Special thanks again to Lil' Sparky... The recipe is truly tremendous!!!

Big10Seaner

Well-Known Member

I like it, nice job!

FishinDave07

Well-Known Member

Killer labels! Where'd you get the blue caps from?

DubbelDach

Well-Known Member

Killer labels! Where'd you get the blue caps from?

homebrewheaven.com - They have blue, green, red, silver, gold, and black. Just used black to bottle pumpkin ale yesterday...

BrewTaster

Well-Known Member

- Joined

- Nov 25, 2008

- Messages

- 103

- Reaction score

- 0

Quick question bout your Manifold. What size is the PVC you used, and what kind of holes and pattern have you drilled into it? Im looking to move to AG soon but was struggling with a manifold or false bottom, that looks like a very suitable solution to me. Does it work well?

DubbelDach

Well-Known Member

DubbelDach

Well-Known Member

Quick question bout your Manifold. What size is the PVC you used, and what kind of holes and pattern have you drilled into it? Im looking to move to AG soon but was struggling with a manifold or false bottom, that looks like a very suitable solution to me. Does it work well?

5/8" OD CPVC... drilled with a 1/8" bit.

I did a straight row right down the middle of the pipe, holes separated by 1/2 inch.

Then I did identical rows on either side of that, but I shifted those rows 1/4" to stagger the rows, if that makes sense.

Seems to work very well, I only vorlauf about 32 ounces before it runs clear. I am having efficiency problems (54%), but I sincerely believe it's the crush at my LHBS. I just bought a mill that I will use Sunday 12/14 for the first time, so we'll see if that fixes it. I'll post here for you if it does.

BrewTaster

Well-Known Member

- Joined

- Nov 25, 2008

- Messages

- 103

- Reaction score

- 0

So essentially 1 row along the top half inch apart, and then a row along each side shifted a quarter off the top ones? so only 3 rows of holes? Also does the manifold rest on the bottom of the cooler?

Sorry for the dumb q's, just wanna make sure to make it right! Keep me posted on the efficiency, and let me say, Deez Nuts look delicious!

Cheers

Sorry for the dumb q's, just wanna make sure to make it right! Keep me posted on the efficiency, and let me say, Deez Nuts look delicious!

Cheers

RandalG

Well-Known Member

For each running do you wait ten minutes in between sparges?

It is. It's MOSTLY for denaturing enzymes while you're doing a rather long fly sparge. If you didn't raise the temp, you'd still be converting over that 45-60 minutes which you may not want. It has a side effect of loosening a bit more sugar but it's absolutely NOT necessary with batch sparging.

The best efficiency I've ever gotten was 94% and it was taking 3 distinct runnings. One following the mash (no mash out infusion), then two runnings following half sparge volume infusions. I don't recommend a mash out infusion unless you want to reduce your number of runnings to two (for a slight reduction is task load/time).

In summary you have two choices:

#1

mash

infuse an amount equal to your grain absorption (about .1 gallons per pound of grain) for your mash out (200F).

stir, vorlauf and drain.

Infuse single batch sparge volume @ 170F, stir, vorlauf and drain.

two runnings, both at elevated temps, relatively high efficiency

#2

mash

vorlauf and drain

add half sparge amount @ 185F, stir, vorlauf, drain

add second half sparge amount @ 185, stir, vorlauf, drain

3 runnings at progressively higher temps, very high efficiency

NorthernBrewer09

Member

Math and what not aside that settled ALOT of questions I had im going to order the supplies and set up my All Grain equipment soon Thanks Buddy

Just brewed this today. I used just over 9.5 gallons of water and ended up with 7 gallons pre-boil. My pre-boil gravity was 1.053 and I ended up with about 6 gallons to go into the Carboy. My OG ended up being 1.058, a bit high for this style of beer. Being my 3rd AG batch and my new Mash Tun, I need to work on my efficiency numbers. As a side note, I ended up with 3 Sparges for this. I took a gravity just before the 3rd Sparge and was still getting 1.029 gravity so decided I would just go ahead and top off my Brew pot (hence 7 gallons).

Bottom line, this was a great tutorial. Thanks

Bottom line, this was a great tutorial. Thanks

Twofox

Well-Known Member

Quick question. What/how did you make the thing you use to measure the volume in your kettle? The graduated cpvc.

Jaysus

Well-Known Member

Poured a gallon in to his kettle at a time and marked as appropriate.

Similar threads

- Replies

- 2

- Views

- 269

- Replies

- 6

- Views

- 395

- Replies

- 2

- Views

- 446

- Replies

- 8

- Views

- 378

- Replies

- 5

- Views

- 373

Latest posts

-

-

-

-

-

For Sale 10 Gallon Full Setup -Nebraska

- Latest: BrewersVocation

-

-

-