Ciderguy

Active Member

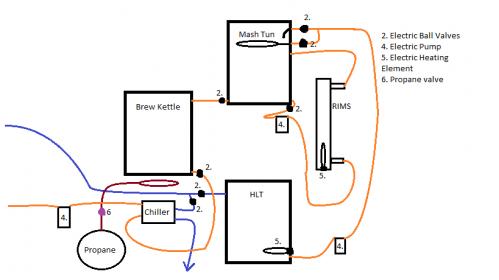

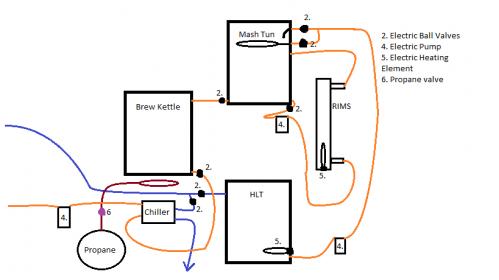

Advice on brewing system please! I have made a simple drawing of what I have in mind. I would like to know if anyone would recommend additional valves in different places to cut down on fluid loss or temperature variation in the lines. Just trying to get a good idea. I am going to run all of the ball valves to switches on a panel, with breakers, HLT will heat with an electric element and a temperature control unit, Mash tun will maintain temp with RIMS heating unit and temp control, and brew kettle will heat with propane and temp control. One question if have is if the pump will run constantly for that entire hour recirculating the mash, is it hard on the pump if I try to slow the flow with the ball valve a little or will i ever need to do so? And will the small amount of grain the comes through at the beginning damage the impeller? Right now I have a simple keggle set-up on my stand but it is all built for a 2 bbl system which I am picking up in July. I will most certainly have additional questions and appreciate any input! The lay out will change with the larger vessels, HLT bottom, Mush tun top (I will be fabricating some kind of a dump), and kettle on the side.