mcfire12

Well-Known Member

- Joined

- Dec 25, 2013

- Messages

- 110

- Reaction score

- 10

Hi guys, i've been brewing using a converted keg boil kettle as well as 2 - 10 gallon yellow coolers for my mash tun and HLT. Started getting into things again and I remember how big of a pain it is to use the gravity system. Also, I really need to knock some time out of brew day for various reasons. Lots of questions so get ready...

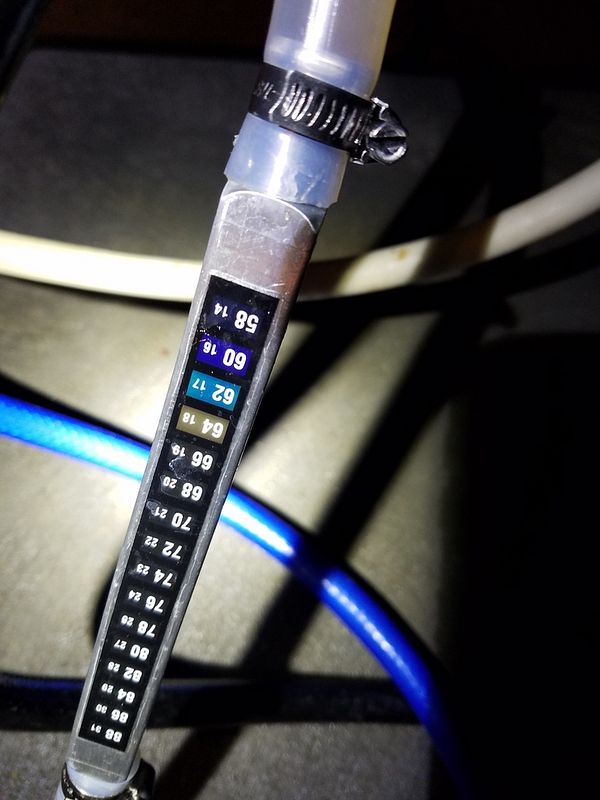

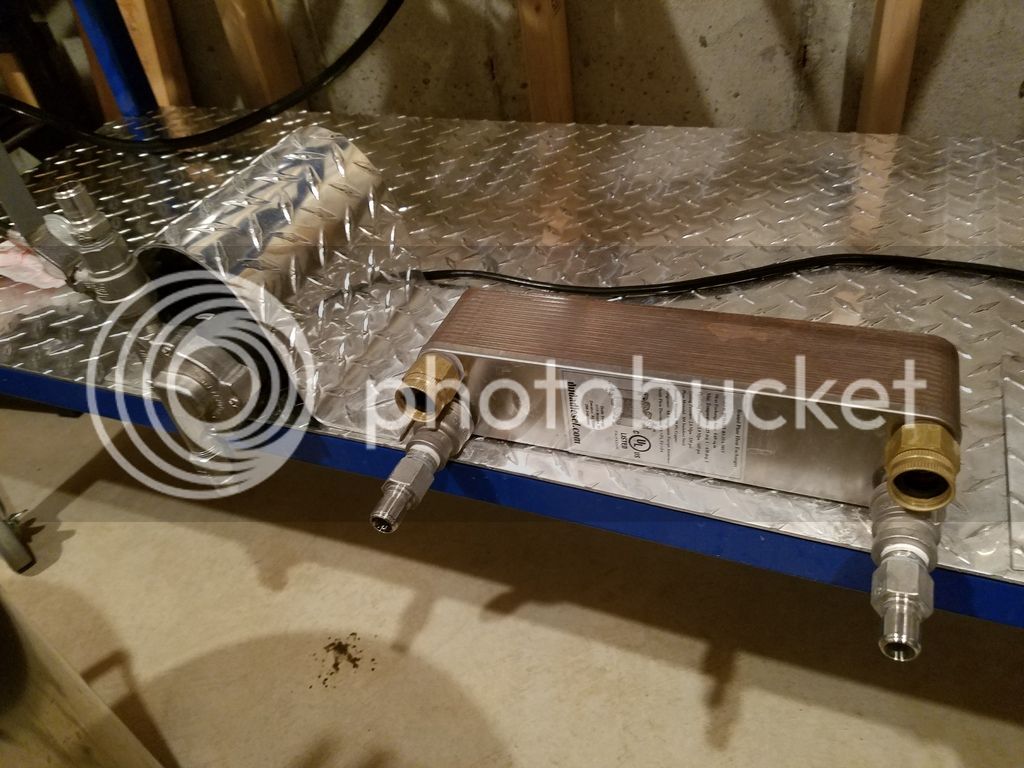

I have done some reading on plate chillers and I know this will knock a LOT of time out for me. I currently use a home made immersion chiller out of a 50 foot roll of copper, the line is pretty small I do not remember the diameter right now. But, last brew it took about 50 mins to chill down to almost ideal pitching temps... something has to be done about it. Now, I read some people use these by gravity, and some by a pump.

I've seen people use their old immersion chiller to set up some kind of herms system.

I only have one burner and stainless keg right now. So I guess how much is a pump and chiller going to benefit me? I batch sparge, and I guess some how this will eliminate the vourlauf (spelling) technique? Can a pump make batch sparging any easier for me? I've read about people recirculating during the mash to get better efficiency as well as to clear the beer.

Maybe I just can't picture in my head how exactly this all comes together. It would be so nice to eliminate the 3 tier system and just be able to have quick connects on stuff. Can someone help me with an equipment list i'll need to upgrade to this type of setup?

Feeling a little overwhelmed with this for some reason, hopefully someone will chime in and help! Thanks in advance!

I have done some reading on plate chillers and I know this will knock a LOT of time out for me. I currently use a home made immersion chiller out of a 50 foot roll of copper, the line is pretty small I do not remember the diameter right now. But, last brew it took about 50 mins to chill down to almost ideal pitching temps... something has to be done about it. Now, I read some people use these by gravity, and some by a pump.

I've seen people use their old immersion chiller to set up some kind of herms system.

I only have one burner and stainless keg right now. So I guess how much is a pump and chiller going to benefit me? I batch sparge, and I guess some how this will eliminate the vourlauf (spelling) technique? Can a pump make batch sparging any easier for me? I've read about people recirculating during the mash to get better efficiency as well as to clear the beer.

Maybe I just can't picture in my head how exactly this all comes together. It would be so nice to eliminate the 3 tier system and just be able to have quick connects on stuff. Can someone help me with an equipment list i'll need to upgrade to this type of setup?

Feeling a little overwhelmed with this for some reason, hopefully someone will chime in and help! Thanks in advance!