iandanielursino

Well-Known Member

- Joined

- Mar 21, 2023

- Messages

- 105

- Reaction score

- 24

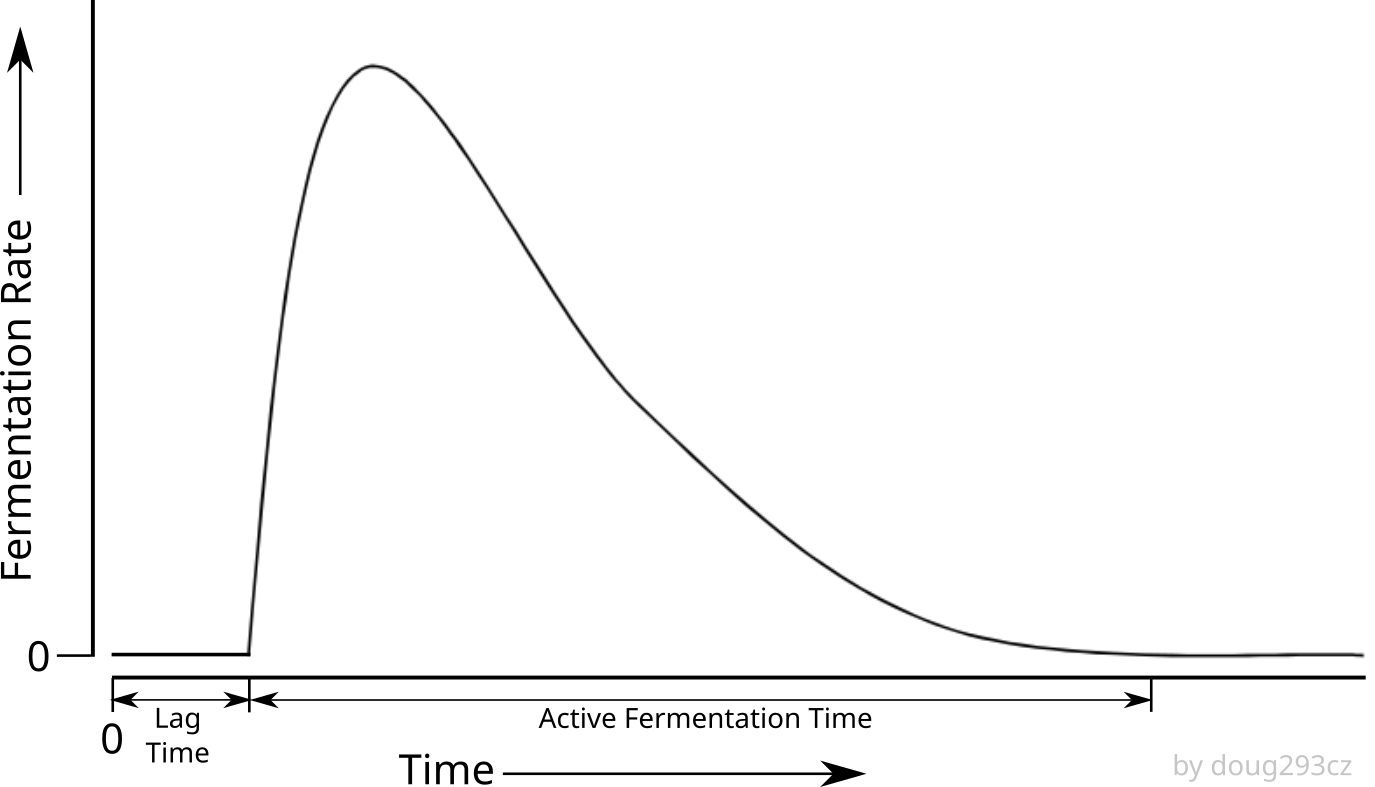

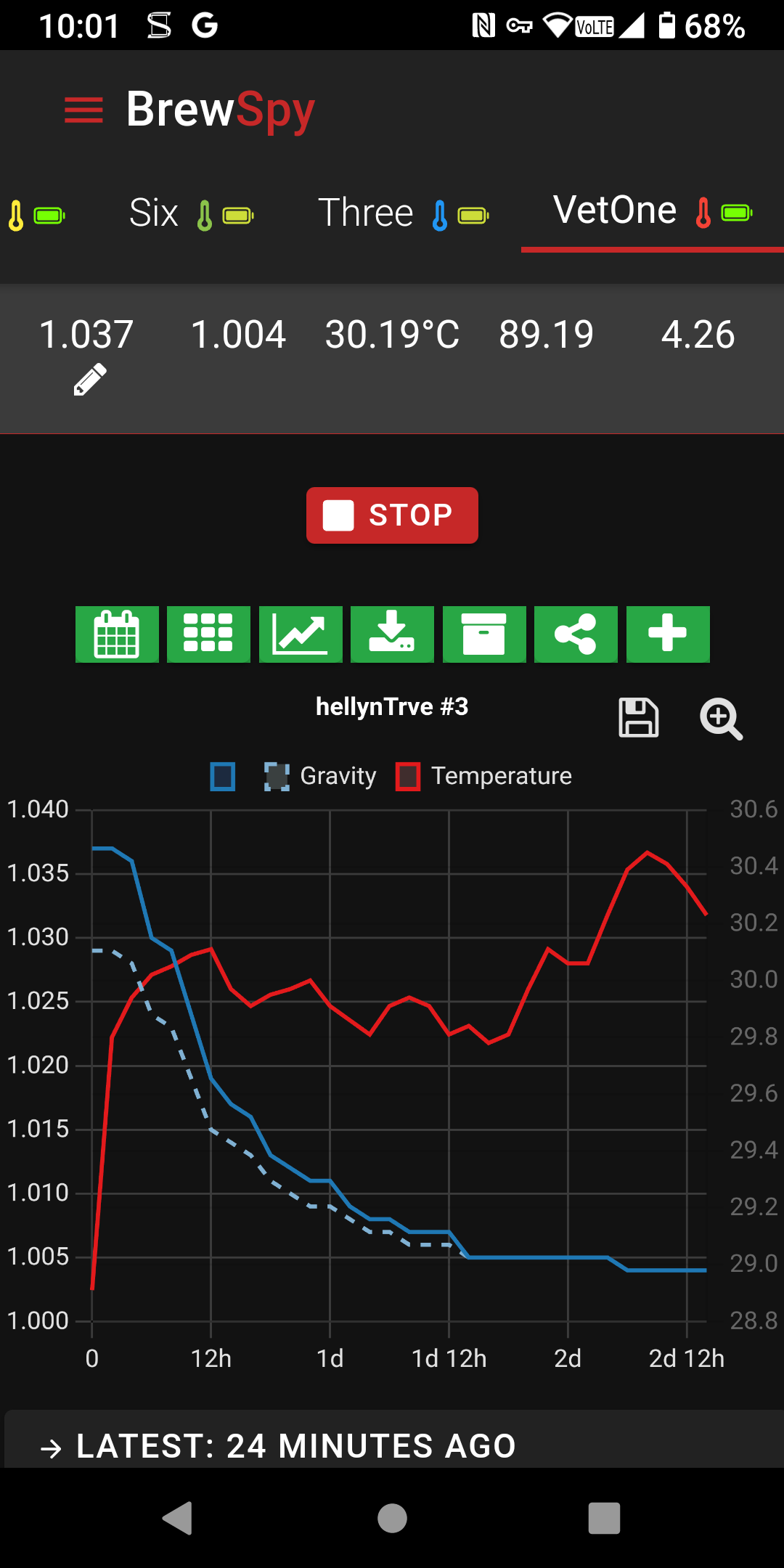

I've seen my equipment (Spike CF10 with PRV) get 12 PSI when it was working properly one time overnight, but that was on the first day of fermentation (I'm in the middle of some troubleshooting with technical support but that's a topic for elsewhere). So this time, on the third afternoon (fourth day after starting fermentation in the evening so about 3.5 days) I started spunding a 5 gallon batch of APA with OG of 1.047, and I should add that the fermentation was slow for the first 24 hours.

In a couple hours I got up to 2.5 PSI, then the next morning it was up to 4 PSI. Is that a normal spund rate for this far into fermentation or is it rather slow?

I'm curious about how fast people usually get up to pressure when spunding, particularly when they have not been doing it the entire fermentation.

In a couple hours I got up to 2.5 PSI, then the next morning it was up to 4 PSI. Is that a normal spund rate for this far into fermentation or is it rather slow?

I'm curious about how fast people usually get up to pressure when spunding, particularly when they have not been doing it the entire fermentation.

Last edited: