PaulHilgeman

Well-Known Member

- Joined

- Mar 14, 2008

- Messages

- 270

- Reaction score

- 7

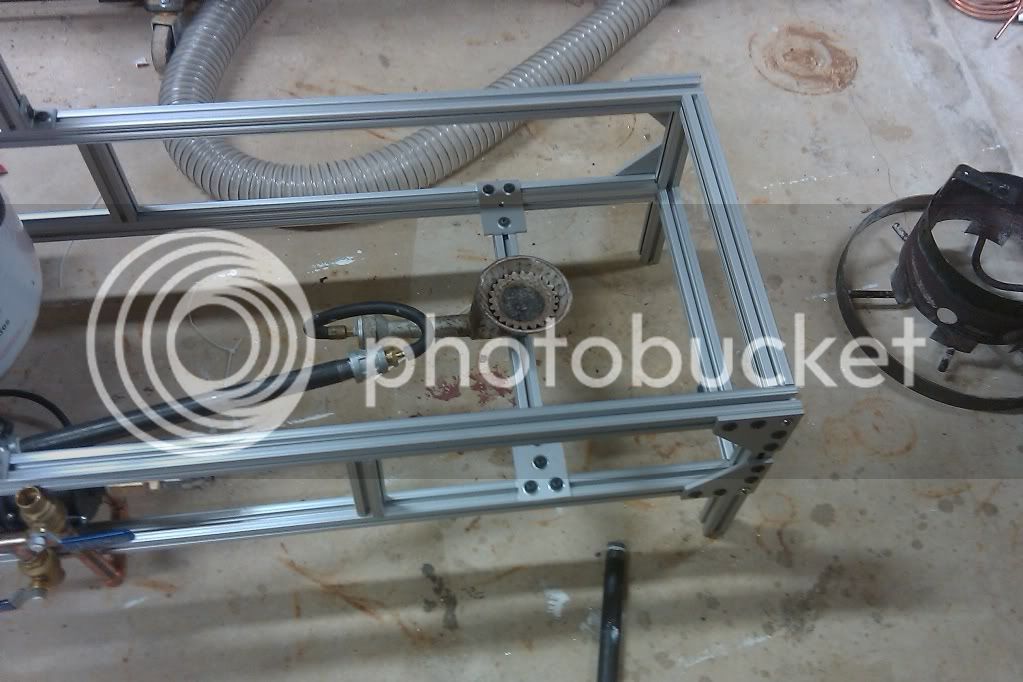

Well, thats exactly how my kettle would be sitting, except that I would be using one of the cheap 'jet' burners. What is the purpose of the steel sections inside of the aluminum frame though? They dont seem to support the kettle at all in that video. My main concern is the flames bending around the kettle and getting the aluminum too hot.

Ok, it looks like I will probably be fine without anything.

Ok, it looks like I will probably be fine without anything.