Bensiff

Well-Known Member

- Joined

- Mar 13, 2008

- Messages

- 4,835

- Reaction score

- 411

I kept telling Kickflip I would post some photos of my build so here it is. Its been really slow going having had my son born last June and now working on moving; but, I get a few hours here and there to work.

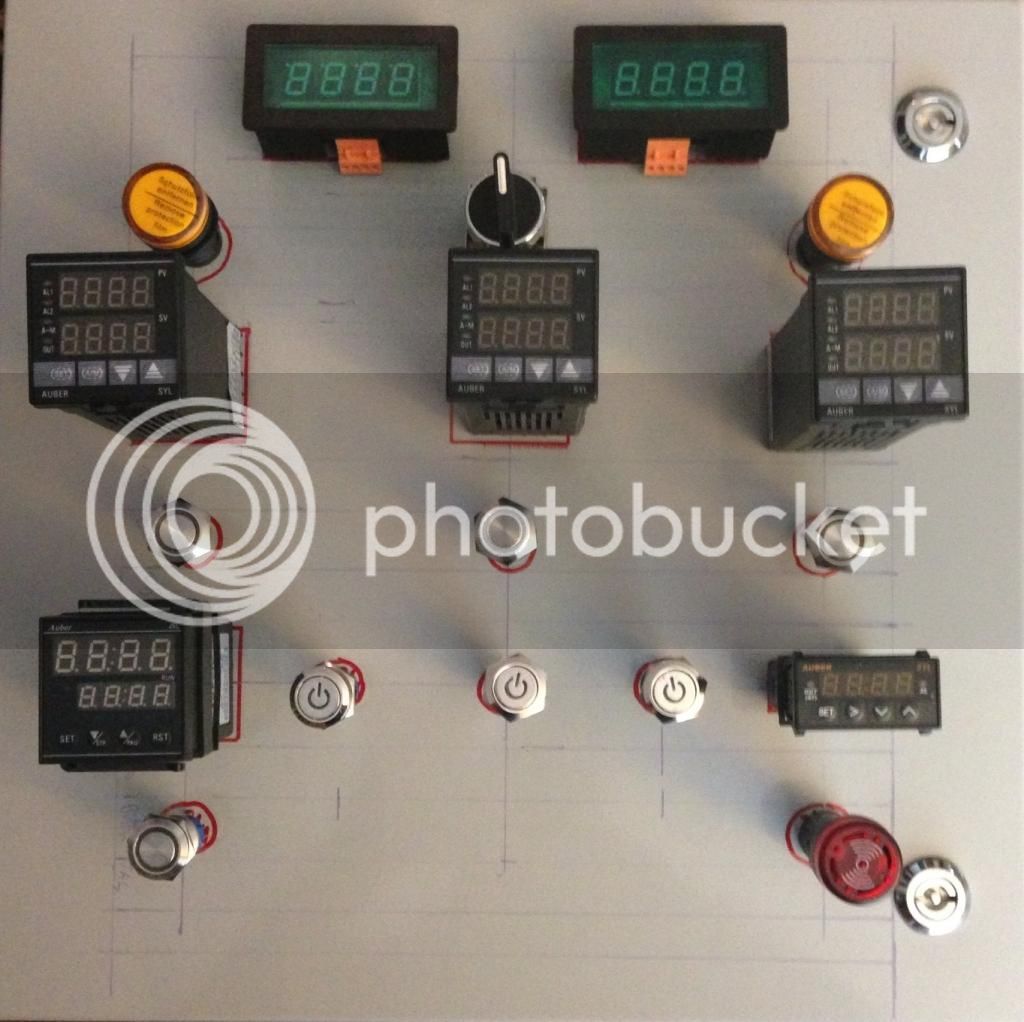

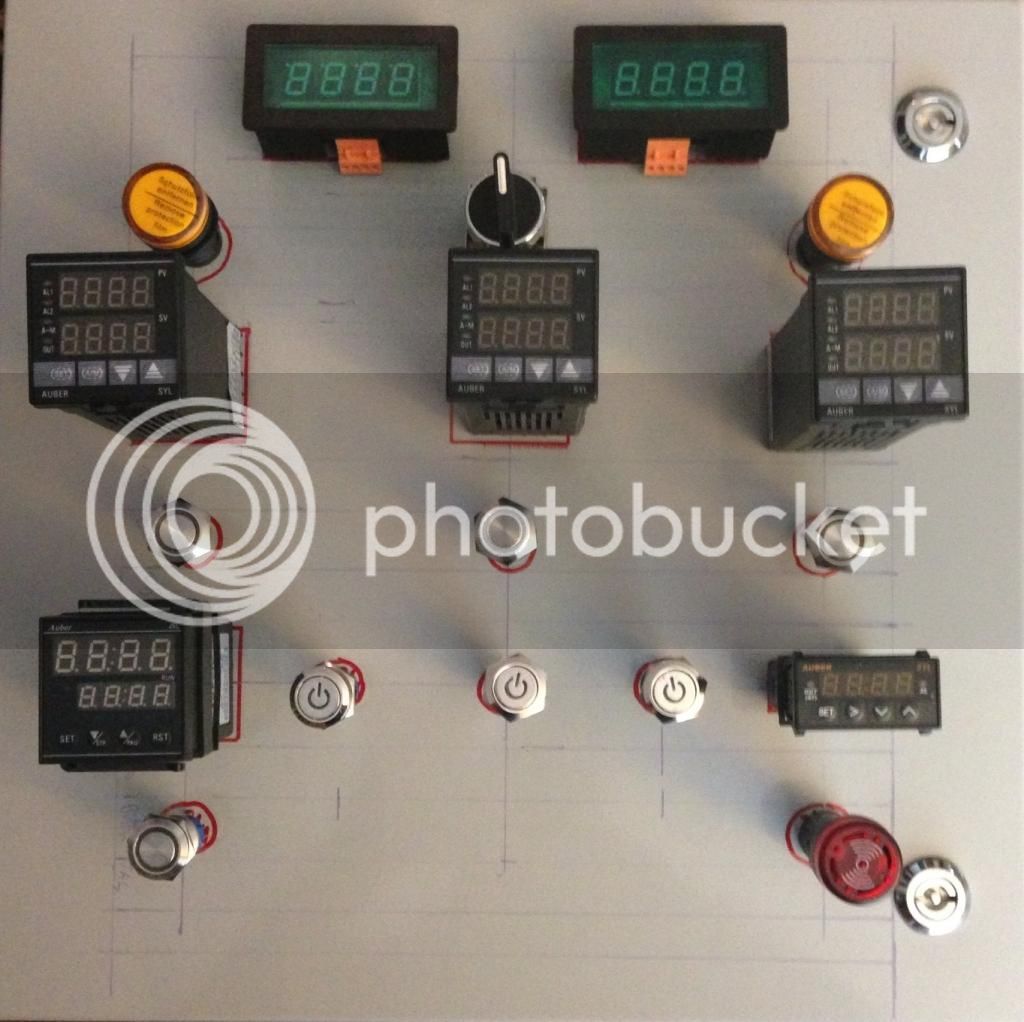

The panel...Kal inspired obviously

Getting ready to make the cuts:

Yup, a HF speed bit works just fine:

Manufacturer primer stripped, ready for some acid etch:

Makeshift paint booth, first coating of U-POL 8:

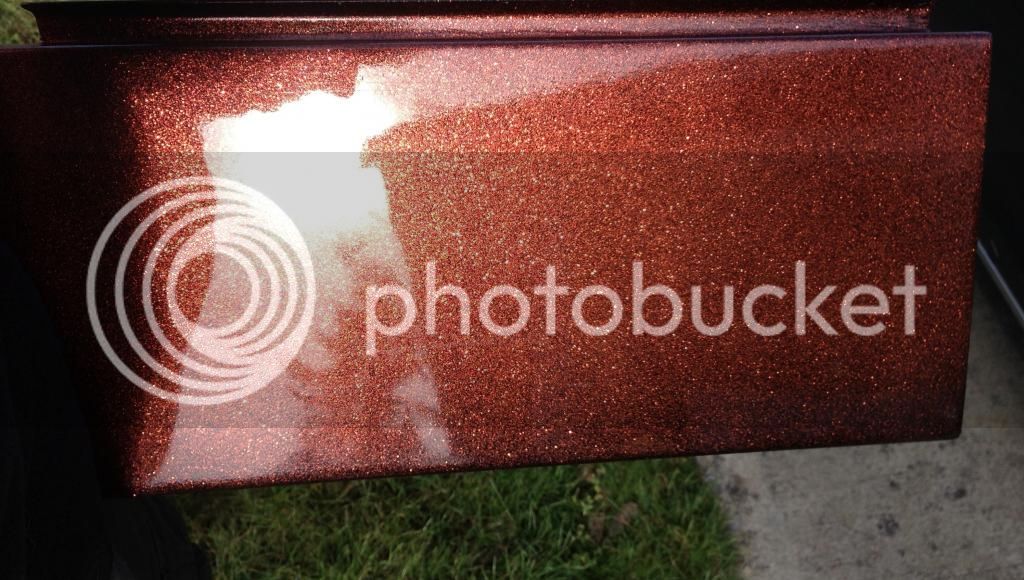

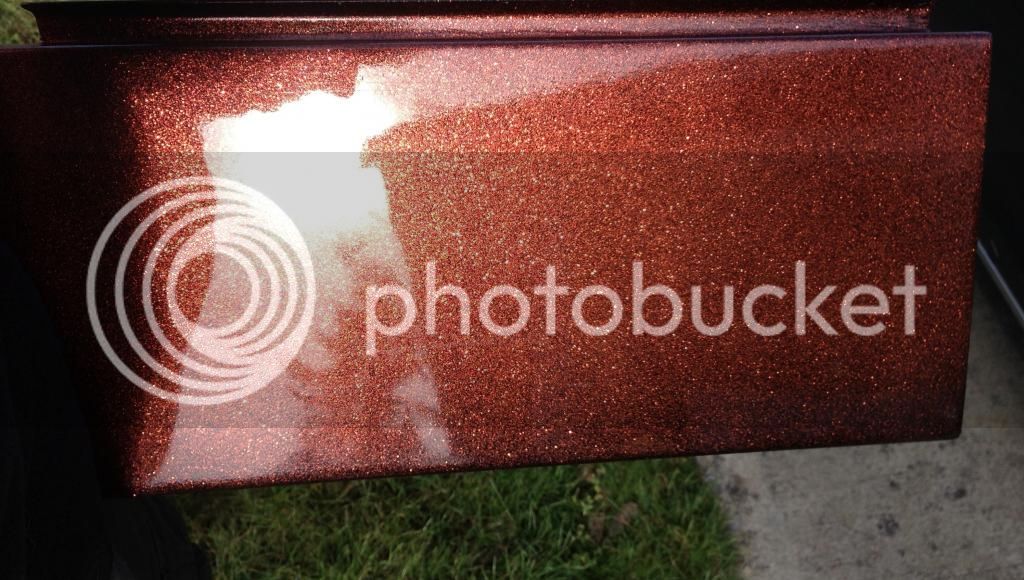

And now your 70's flashback, some good ol' metal flake...black base with copper metal flake:

Beginning to install:

The panel...Kal inspired obviously

Getting ready to make the cuts:

Yup, a HF speed bit works just fine:

Manufacturer primer stripped, ready for some acid etch:

Makeshift paint booth, first coating of U-POL 8:

And now your 70's flashback, some good ol' metal flake...black base with copper metal flake:

Beginning to install: