n8huntsman

Active Member

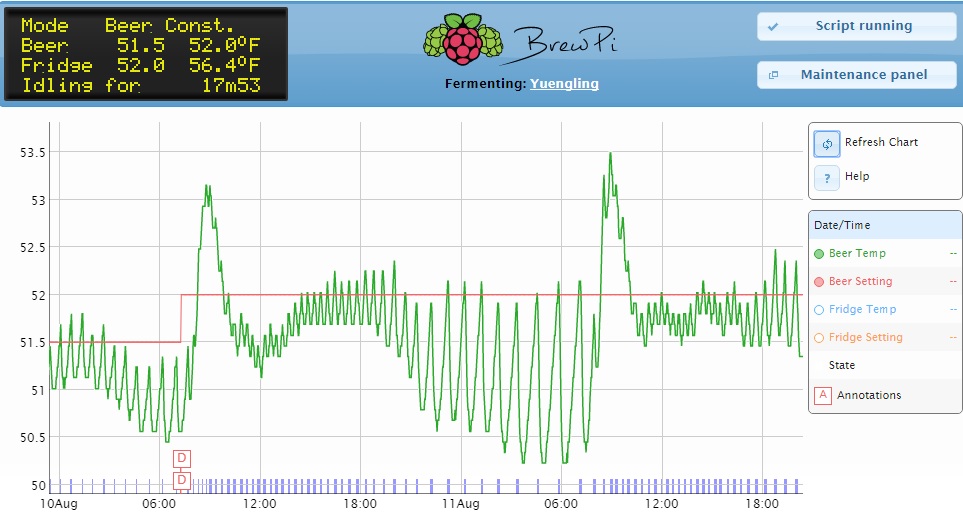

So I know I screwed up, just wondering what my best option is? I have always done IPA's, stouts, ales, etc and never did a starter and had good luck. I attempted the same to make a lager in my new fermentation fridge and brewpi setup. I chilled with a wort chiller to 75°, placed it in the fridge and allowed it to drop to 70° over a couple hours. Pitched a single package of liquid WLP800 per the instructions but after doing some more research I see that is not advised. I allowed it to cool throughout the night down to 52.5°. That was Saturday, 8/6/16. It's now Tuesday 8/9/16 and there is no discernible fermentation going on based specific gravity (1.05) or on the air lock activity. One interesting thing is that the temperature fluctuations in the fridge seem to be causing the air lock to reverse half of the day. The beer warms a few degrees in the day time but as it cools at night the fermenter has a slight negative pressure. I need to tweak the brewpi a bit to lessen the beer fluctuation but as it is, it's only a few degrees.

Should I immediately pitch another package or two of WLP800 in the essence of time, or get a package and make a starter, wait for that to take off and pitch the starter into the wort? Or is there something else I should try?

Should I immediately pitch another package or two of WLP800 in the essence of time, or get a package and make a starter, wait for that to take off and pitch the starter into the wort? Or is there something else I should try?