Unfortunately, there is some incorrect and missing information on this thread. Yes, thermoelectric devices are inefficient. That may or may not be a good reason to avoid them. Given a highly insulated chamber, they can work well and have duty cycle minimized thereby reducing electricity. This is priority number one.

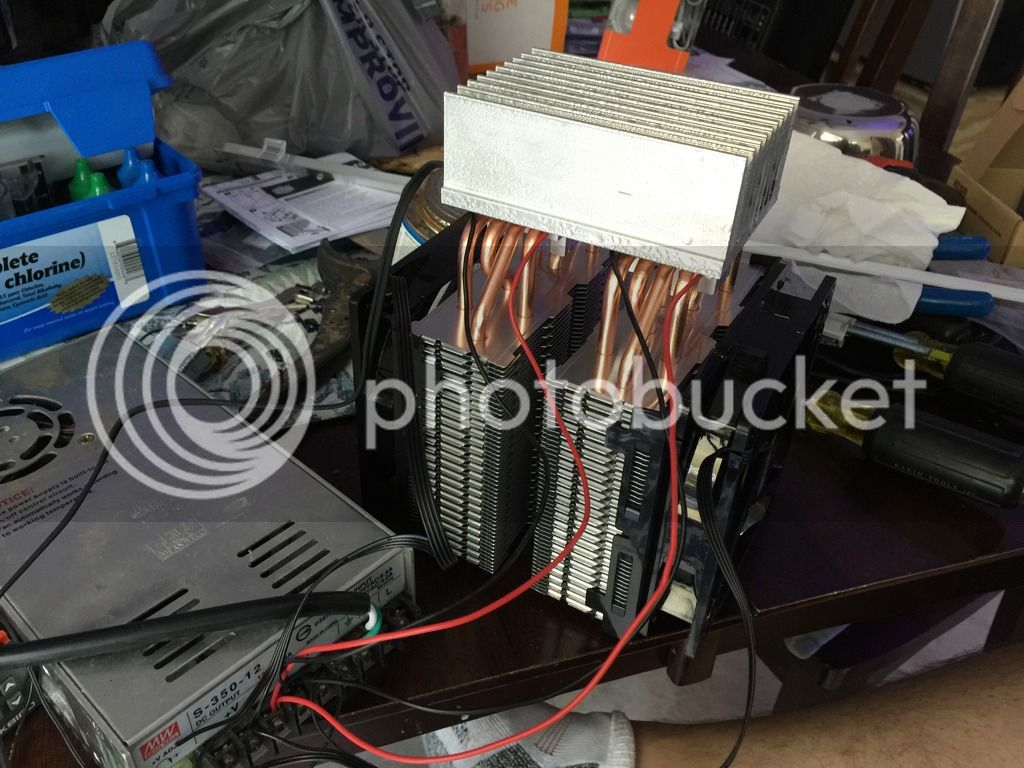

TEC's are simple heat pumps, and generate lots of heat in the process. Hence the inefficiency. As a general rule, for any amount of heat they pump, they create 3x as much. Therefore a very efficient heat sink must be used. In order to reach the scale we need, that heat sink MUST be liquid cooled on the hot side. It can be used on both sides if practical. Of course this adds complexity: one or two liquid pumps, coolant (which should be better than the minimum of distilled water), reservoirs, and heat exchangers (radiators plus fans for coolant:air transfer).

The other problem is as the temperature differential increases, their pumping ability drops. Compressor driven refrigerations don't suffer to nearly this degree. So you might quickly pump out the first few degrees, but the next few are more difficult. Add that to the cool side targets increased heat transfer across its insulation and it gets tricky.

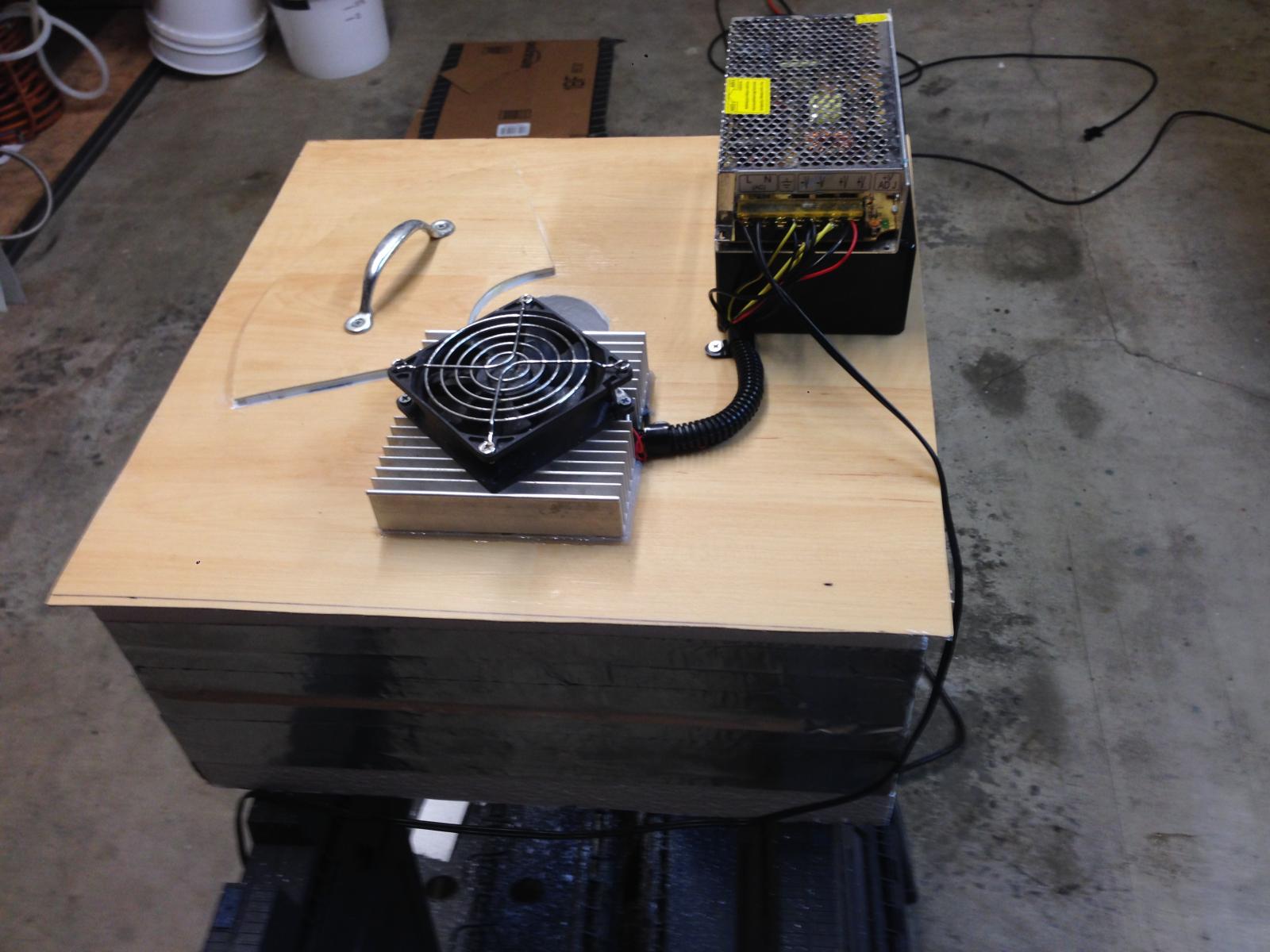

If I were to make one, and I almost did, I would use 2 or three maximum amp TEC's. Like ~25 amps at 12V. I would use copper blocks appropriately sized and large (like over 100 in^2) radiators, plus strong fans on the radiators. Most of this stuff is available as high-end PC cooling hardware. The problem is this is several hundred dollars worth of hardware, and we know you could probably get a used glycol chiller for not much more, or create the DIY with a window AC or dehumidifier and cooler.

But the upside is cool (pun intended). They can be switched on and off quickly so can be controlled by PID. They can be nearly silent, and are fairly durable as long as cooled appropriately. Also, they can be reversed to provide heating rather than cooling.

In summary, very possible, just not that practical, especially given costs. Add electric costs downstream as AD points out and it's not a winning proposition.