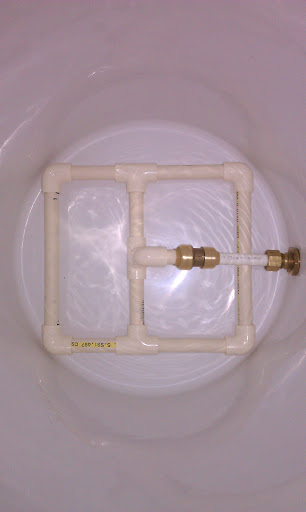

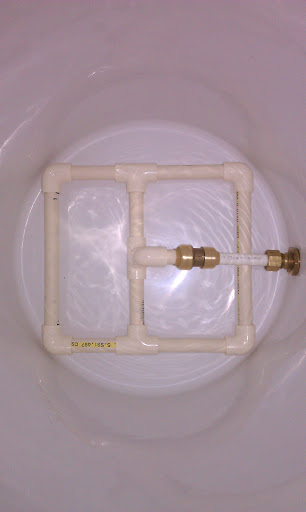

I have been having nothing but trouble with a false bottom in my 10 gallon Igloo mash tun so I just took it out and make a CPVC manifold. 1/2" pipe with hack saw cuts every half inch on the bottom side.

What is the best way to drain the mash tun with a manifold like this (i.e. open it full bore, let it go slowly at first, etc.)? I am doing a wheat beer next and would like to avoid a stuck sparge if I can.

What is the best way to drain the mash tun with a manifold like this (i.e. open it full bore, let it go slowly at first, etc.)? I am doing a wheat beer next and would like to avoid a stuck sparge if I can.