Sizz

Well-Known Member

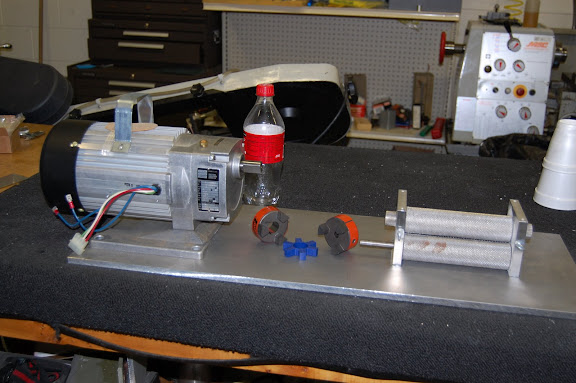

I have a 6" 3-roller monster mill. My corded drill is struggling with this thing and I have to run it full speed or it'll lock up. The grain is shot out more than it's actually being crushed. I've been looking for motors and I'd prefer to have a direct driven motor. I found this used bodine and it's beefy, with 180in/lbs & 154RPM. I guess what I need to know is if anyone has encounter a motor not strong enough for a 6" roller mill and what the specs were.

Surplus Center Item Detail

Surplus Center Item Detail