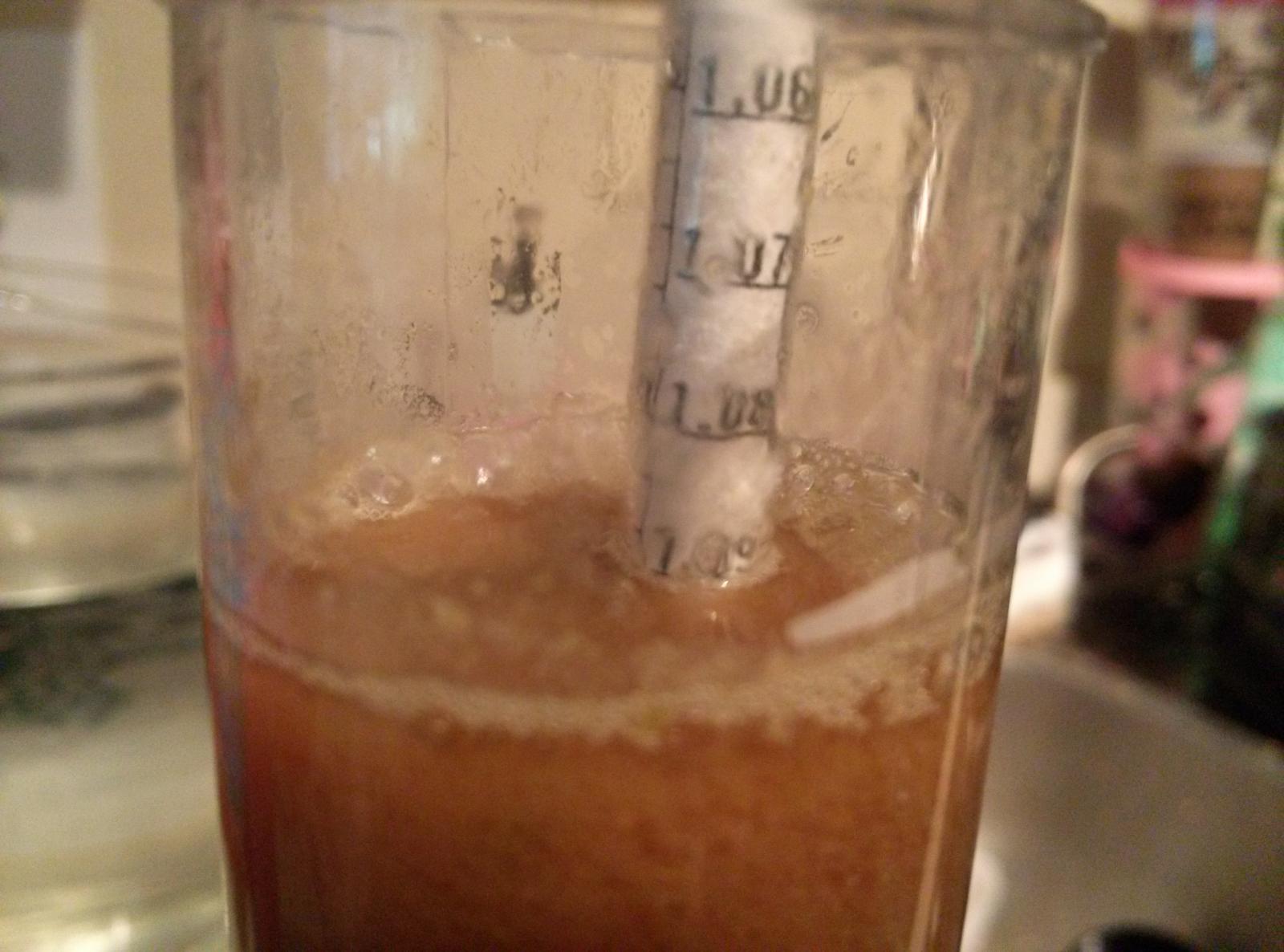

So you did a partial boil all grain batch? We probably don't know the true OG then, you may have had some mixing error but also likely a much lower OG then you were aiming for if you topped off a whole 50%. It is possible to do a partial boil with all grain, I sometimes do when I want 5 gals on my 3 gal system, but you need to account for efficiency loss from doing such a small sparge. I usually max out around the low 1.050's. This looks like it's supposed to be about 1.060-1.065 finished, if you tried to do it as 2.5 gal partial boil that means the post boil wort would need to be 1.120 or thereabouts. Were you just way off on volumes or did you plan to do it that way?