Welcome to my Cider Story

Since I was young I always had a love for beverages, whether it be a warm glass of milk or an ice cold Coke. This love of course didn't change when I grew older, if anything it intensified. My love of beverages transformed into a love of alcohol, not just tasting it and consuming it but how it is put together, the Genetics of Alcohol if you like.

I have always wanted to brew alcohol, always. The problem was that I was constantly moving around and not living in once place long enough to really get into manufacturing beer. Now it all changes.

I grew up in Great Britain where I was surrounded by great scotches, flooded with countless Ales and circled with great British Ciders. Ciders being my favorite (currently). So now living in Tuscon Az where I will be settled for three years I am now ready for to undertake a Home brewing challenge. The challenge I have chosen is to brew Cider.

My thoughts are that instead of diving straight into brewing I'm going to do as much research and take on as much advise as I can get. I have spent countless amount of hours searching through these forums and have gained so much information with everyone's experience and experiments.

The Plan

I plan on making two 2-gallon batches of Cider. Plain apple being 5-6% and the apple fruit medley about 5-6% as well.

Batch 1

This batch I would like to keep just plain Apple

Batch 2

This second batch I would like to keep the Apple flavour but add to it, possibly Raspberries or Blackberries preferably Elder Flower if I can locate it to which I would then add lime.

What I know so far.

So, this is the process I will be taking when making my batches.

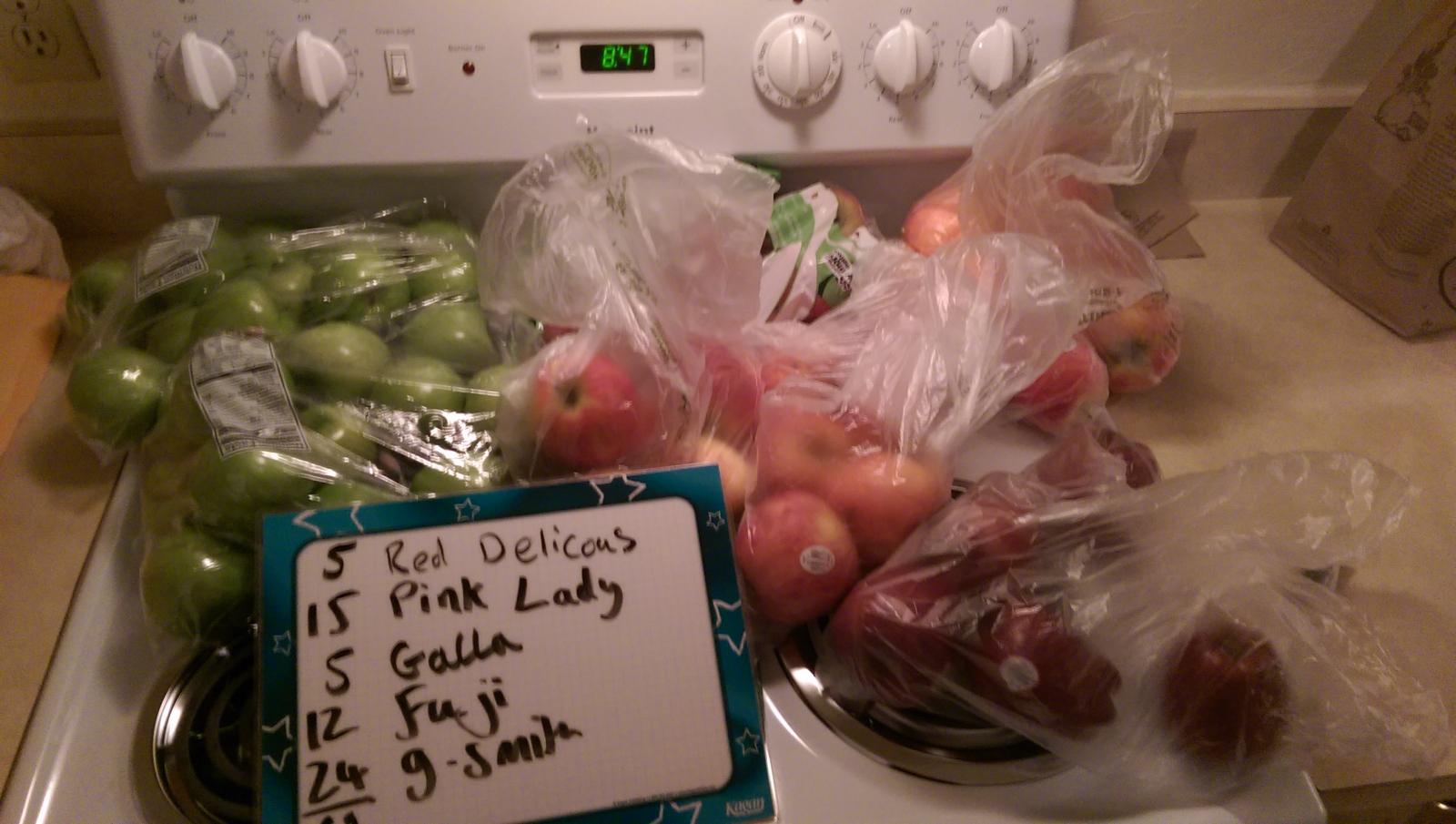

1. Juice fresh apples after cleaning them. I will be using a selection of apples.

2. Crush and Add 2 Camden Tablets and wait 12 hours.

3. Add Pectic Enzyme and wait another 12 hours and then add a source of sugar, Probably Honey.

4. Add Yeast

5. Split 4 gallon batch into two 2-gallon Batches

6. First Batch I would leave to ferment in Primary

7. Second Batch I would add some more fruit, e.g raspberry, blackberry or elderflower and lime. Then leave to ferment.

8. I would then move both batches to 2 secondary Carboys for further fermenting.

9. Then I would backsweaten.

10. When Cider is clear and my Hydrometer is where I want it, I will then bottle buy using half a tea spoon of sugar per 330ml bottle.

So I know my method has a few holes in it so I do have a few questions if my fellow members could help me out with.

1. Do I take the cork out of the apples before I press them?

2. How much Pectic Enzyme should I add for 4 Gallons of Juice.

3. Do I add the Sugar (Honey) after the p enzyme ad before the yeast? Do I add the yeast Nutrients with the yeast?

4. At what point should I remove 1 gallon of juice to back sweaten?

5. How long do I know to leave the cider in the primary before moving to secondary?

6. Should I put extra fruit (raspberry, blackberry) in the secondary as well as the primary?

7.When do I back sweaten.

8. What can I use to sterilize my equipment that I can buy from somewhere like walmart?

Any advice and help would be more than welcome.

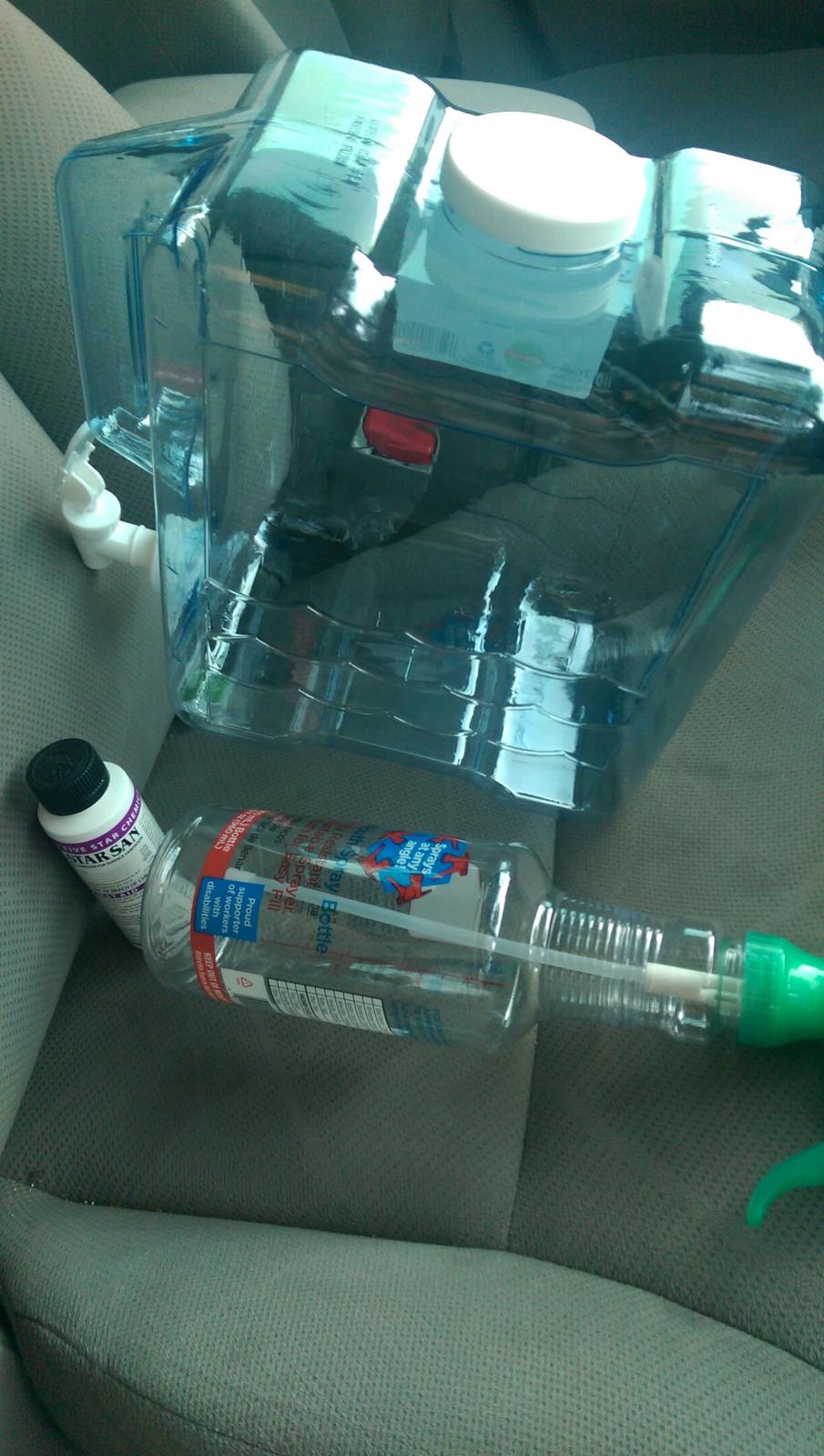

So far this is my equipment.

Since I was young I always had a love for beverages, whether it be a warm glass of milk or an ice cold Coke. This love of course didn't change when I grew older, if anything it intensified. My love of beverages transformed into a love of alcohol, not just tasting it and consuming it but how it is put together, the Genetics of Alcohol if you like.

I have always wanted to brew alcohol, always. The problem was that I was constantly moving around and not living in once place long enough to really get into manufacturing beer. Now it all changes.

I grew up in Great Britain where I was surrounded by great scotches, flooded with countless Ales and circled with great British Ciders. Ciders being my favorite (currently). So now living in Tuscon Az where I will be settled for three years I am now ready for to undertake a Home brewing challenge. The challenge I have chosen is to brew Cider.

My thoughts are that instead of diving straight into brewing I'm going to do as much research and take on as much advise as I can get. I have spent countless amount of hours searching through these forums and have gained so much information with everyone's experience and experiments.

The Plan

I plan on making two 2-gallon batches of Cider. Plain apple being 5-6% and the apple fruit medley about 5-6% as well.

Batch 1

This batch I would like to keep just plain Apple

Batch 2

This second batch I would like to keep the Apple flavour but add to it, possibly Raspberries or Blackberries preferably Elder Flower if I can locate it to which I would then add lime.

What I know so far.

So, this is the process I will be taking when making my batches.

1. Juice fresh apples after cleaning them. I will be using a selection of apples.

2. Crush and Add 2 Camden Tablets and wait 12 hours.

3. Add Pectic Enzyme and wait another 12 hours and then add a source of sugar, Probably Honey.

4. Add Yeast

5. Split 4 gallon batch into two 2-gallon Batches

6. First Batch I would leave to ferment in Primary

7. Second Batch I would add some more fruit, e.g raspberry, blackberry or elderflower and lime. Then leave to ferment.

8. I would then move both batches to 2 secondary Carboys for further fermenting.

9. Then I would backsweaten.

10. When Cider is clear and my Hydrometer is where I want it, I will then bottle buy using half a tea spoon of sugar per 330ml bottle.

So I know my method has a few holes in it so I do have a few questions if my fellow members could help me out with.

1. Do I take the cork out of the apples before I press them?

2. How much Pectic Enzyme should I add for 4 Gallons of Juice.

3. Do I add the Sugar (Honey) after the p enzyme ad before the yeast? Do I add the yeast Nutrients with the yeast?

4. At what point should I remove 1 gallon of juice to back sweaten?

5. How long do I know to leave the cider in the primary before moving to secondary?

6. Should I put extra fruit (raspberry, blackberry) in the secondary as well as the primary?

7.When do I back sweaten.

8. What can I use to sterilize my equipment that I can buy from somewhere like walmart?

Any advice and help would be more than welcome.

So far this is my equipment.