OEHokie

Well-Known Member

Hey everybody,

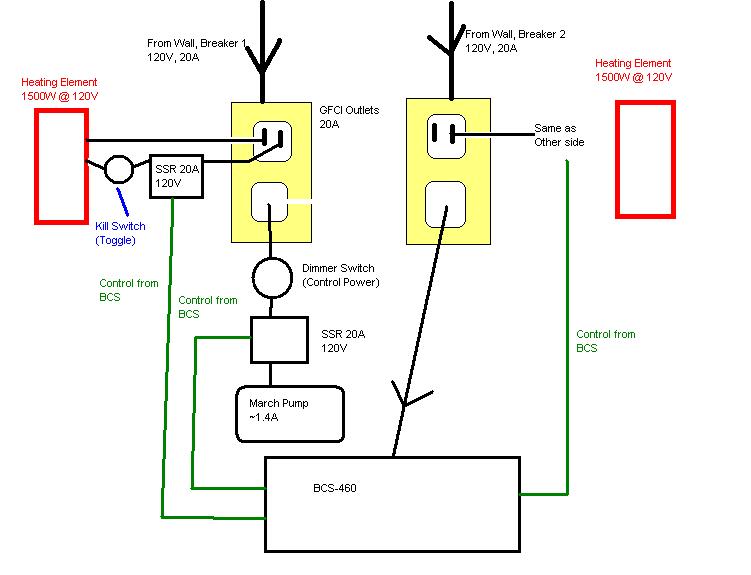

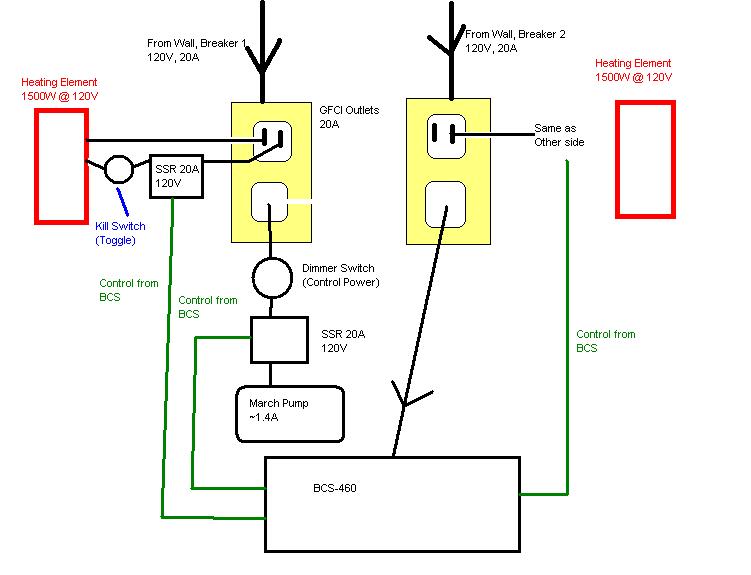

I need some help with some pretty simple wiring questions. I'm using two 1500W Heating elements on two different 20A circuit breakers via non-GFCI outlets.

Background/Assumptions:

On outlet A, I'm hooking up one heating element and a march pump. Both probably won't be on at the same time (at least most of the time). March pumps supposedly operate at 1.4A, and I will be installing a dimmer switch to vary the power to it. I'm also thinking of installing a switch to bypass the SSR so I can turn it on manually (3-way switch I guess, not drawn). So... heating element (1500W/120V + 1.4A = 13.9A)

On outlet B, I'm hooking up the other heating element and the BCS-460. I don't know how much power the BCS-460 will pull, but I don't think it will be much, especially compared to the march pump.

The BCS-460 will be controlling the SSRs attached to the heating elements and march pump. Between the heating element and SSR, I will have a kill switch... essentially I have to "arm" the heating elements before they can be used.

I may eventually add solenoid valves into the mix, but they're a bit pricey. At most three would be on at any one time and they draw a little less than 0.2A each (@120V), so 0.6A extra. These would probably go on Outlet B.

Questions:

Since I'm plugging these into the 20A (non-GFCI) outlets, should I bother with getting 20A GFCI outlets for inside my box, or should I just go with 15A GFCI outlets? (I'm leaning towards the 15A ones).

-Answered: Wouldn't I need a 20A cable to go from my control box to the wall outlet (which probably isn't rated for 20A, but is on a 20A breaker)? EDIT: If I went with 20A GFCI Box outlets I'd need a 20A cable.

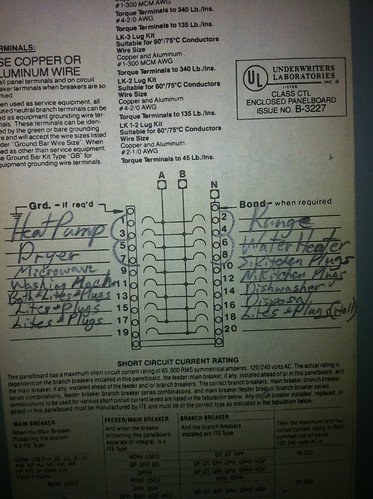

New Question: Is there a way to check the outlet if it is capable of 20A? Probably by taking the cover off and looking for something?

Answered: Is it ok to assume that my current draw won't exceed 15A given the highest draw would be from the heating element + march pump (13.9 < 15)? No it's not

Answered: Is it ok to run the march pump off a dimmer switch like that? I was thinking of a regular light dimmer switch, since I know it can handle 120V vs a potentiometer. It might not work the way I think it does. The BCS and SSR can probably give a PWM signal to the motor to handle adjusting the speed.

Answered: Could I run the heating elements off a dimmer switch to effectively change their power? (would give me more control, could automate this using a servo later) Need to get a big enough dimmer switch, but I probably will just relay on the BCS turning the elements on and off anyways. Less hassle that way.

Answered: For grounding: Does everything share the same ground (even the two separate outlets)? Is there any danger in having a "universal" ground?

New Question: For the cable between the wall and my control box. I'd like something like a computer desktop power cable, I believe they use what's called IEC connectors (?) Is there a good source for these that are 20A rated?

New Question: On the inside of the box, at the connector, I plan on wiring it to GFCI outlets (using the appropriate gauge wire) for inside the box to connect the components to... Anything wrong with that?

Is there anything clearly wrong with my proposed setup?

I'm fairly confident I can go with the 15A route, but wanted to double-check before I started ordering supplies.

Edit 1: Now I'm leaning more towards the 20A route, going to check the outlets when I get home.

Edit 2: Due to my apartments wiring, I'm going to go with a dual 15A setup and set it up so that the March pump and corresponding heating element can NOT be on SIMULTANEOUSLY.

I need some help with some pretty simple wiring questions. I'm using two 1500W Heating elements on two different 20A circuit breakers via non-GFCI outlets.

Background/Assumptions:

On outlet A, I'm hooking up one heating element and a march pump. Both probably won't be on at the same time (at least most of the time). March pumps supposedly operate at 1.4A, and I will be installing a dimmer switch to vary the power to it. I'm also thinking of installing a switch to bypass the SSR so I can turn it on manually (3-way switch I guess, not drawn). So... heating element (1500W/120V + 1.4A = 13.9A)

On outlet B, I'm hooking up the other heating element and the BCS-460. I don't know how much power the BCS-460 will pull, but I don't think it will be much, especially compared to the march pump.

The BCS-460 will be controlling the SSRs attached to the heating elements and march pump. Between the heating element and SSR, I will have a kill switch... essentially I have to "arm" the heating elements before they can be used.

I may eventually add solenoid valves into the mix, but they're a bit pricey. At most three would be on at any one time and they draw a little less than 0.2A each (@120V), so 0.6A extra. These would probably go on Outlet B.

Questions:

Since I'm plugging these into the 20A (non-GFCI) outlets, should I bother with getting 20A GFCI outlets for inside my box, or should I just go with 15A GFCI outlets? (I'm leaning towards the 15A ones).

-Answered: Wouldn't I need a 20A cable to go from my control box to the wall outlet (which probably isn't rated for 20A, but is on a 20A breaker)? EDIT: If I went with 20A GFCI Box outlets I'd need a 20A cable.

New Question: Is there a way to check the outlet if it is capable of 20A? Probably by taking the cover off and looking for something?

Answered: Is it ok to assume that my current draw won't exceed 15A given the highest draw would be from the heating element + march pump (13.9 < 15)? No it's not

Answered: Is it ok to run the march pump off a dimmer switch like that? I was thinking of a regular light dimmer switch, since I know it can handle 120V vs a potentiometer. It might not work the way I think it does. The BCS and SSR can probably give a PWM signal to the motor to handle adjusting the speed.

Answered: Could I run the heating elements off a dimmer switch to effectively change their power? (would give me more control, could automate this using a servo later) Need to get a big enough dimmer switch, but I probably will just relay on the BCS turning the elements on and off anyways. Less hassle that way.

Answered: For grounding: Does everything share the same ground (even the two separate outlets)? Is there any danger in having a "universal" ground?

New Question: For the cable between the wall and my control box. I'd like something like a computer desktop power cable, I believe they use what's called IEC connectors (?) Is there a good source for these that are 20A rated?

New Question: On the inside of the box, at the connector, I plan on wiring it to GFCI outlets (using the appropriate gauge wire) for inside the box to connect the components to... Anything wrong with that?

Is there anything clearly wrong with my proposed setup?

I'm fairly confident I can go with the 15A route, but wanted to double-check before I started ordering supplies.

Edit 1: Now I'm leaning more towards the 20A route, going to check the outlets when I get home.

Edit 2: Due to my apartments wiring, I'm going to go with a dual 15A setup and set it up so that the March pump and corresponding heating element can NOT be on SIMULTANEOUSLY.