What you described will work. There are two reasons you don't see it very often:

1. You have to get the white wire run safely through from the outside to the controller. All the wires needed are already accessible on the outside.

2. Mounting the controller inside can allow condensation to form on the circuit boards.

Regarding point # 2 (a very valid point), has anyone ever tried encapsulating the controller in some type of spray foam? Does anyone know if there is a spray foam thats safe to use on exposed 110v AC?

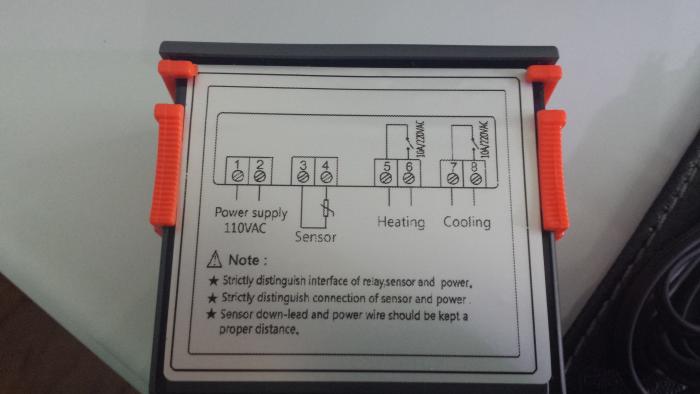

I would really like to install my new STC-1000 as an integrated part of the freezer (only for looks, not necessarily wired directly in) but the talk of condensation has me somewhat worried.