esp

Active Member

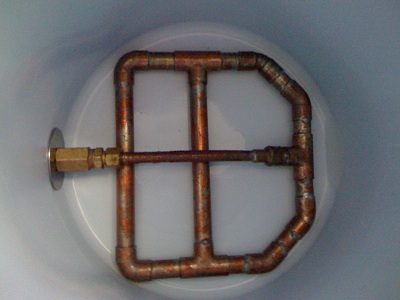

I just bought my 5gal round cooler to start building my all grain set up. I have a bunch of leftover soft copper tubing from some projects I've done around the house. What I can't seem to figure out is how to bend the copper tubing into a circle to fit into the bottom of the cooler. Tubing benders are great for 45's and 90's but they aren't great at making circles. The spring-like tubing protectors work well at keeping kinks out, but it's hard to bend the copper when it's only a few inches long.

Has anyone built a circular manifold? Is there any benefit to circular over square?

Has anyone built a circular manifold? Is there any benefit to circular over square?