ajmartinez

Well-Known Member

This is getting way ahead of myself, since my first brew is only 46hrs into primary fermentation, but that has never stopped me before. Anyhow, I ultimately want to be able to do all-grain brews. There's nothing that would keep me from doing extract brews in an all-grain setup, I'd just use less of the equipment on the bench. Sounds like a deal to me.

After reading countless threads here, I came up with an idea or three for my own setup. Gravity is cheapest to construct, since no pumps are involved. Probably easier to sanitize too. The problem I see is vertical height. I'd like to be able to do everything without a ladder, or having several gallons of very hot water above my head. A single tier system looks awesome, but requires a few pumps and valves. These are not cheap, and present some hurdles in the sanitizing realm. I'm sure sanitizing is not all that difficult, since a ton of people brew a ton of beer in their very own single tier systems, so I am not too concerned about introducing a pump, or valves, to my setup. Money is the big issue here.

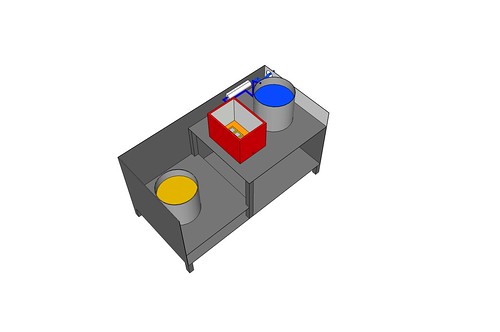

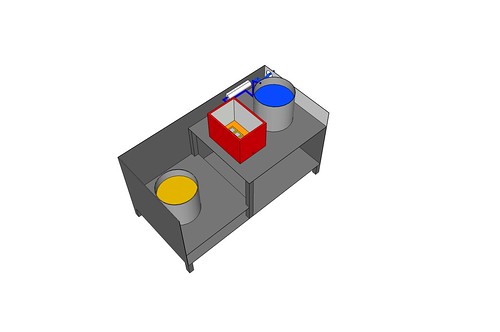

What I've come up with is a two tier system, with the HLT (hot liquor tank) and MLT (Mash/Lauter Tun) on the upper tier, and the brew kettle on the lower tier. I plan to use one pump, with a manifold on the intake and output to let me switch between input/output destinations. One input will pump from the HLT and output to the MLT. I'll valve the HLT input shut, and open the MLT input to circulate until sparging time. Gravity will feed the post-sparge sweet wort into the brew kettle, which will input into the pump again for a trip through a crossflow cooler and into a carboy for the yeast pitch and primary fermentation.

I've not yet made enough progress in Google Sketchup, a few of its features are driving me batty, to show all the components just yet. What I do have, is below.

Any feedback from folks that have done this before is definitely welcome. I spent a long time surrounded by the good-idea fairy (field-grade officers), so don't worry about discouraging me. I can take it.

After reading countless threads here, I came up with an idea or three for my own setup. Gravity is cheapest to construct, since no pumps are involved. Probably easier to sanitize too. The problem I see is vertical height. I'd like to be able to do everything without a ladder, or having several gallons of very hot water above my head. A single tier system looks awesome, but requires a few pumps and valves. These are not cheap, and present some hurdles in the sanitizing realm. I'm sure sanitizing is not all that difficult, since a ton of people brew a ton of beer in their very own single tier systems, so I am not too concerned about introducing a pump, or valves, to my setup. Money is the big issue here.

What I've come up with is a two tier system, with the HLT (hot liquor tank) and MLT (Mash/Lauter Tun) on the upper tier, and the brew kettle on the lower tier. I plan to use one pump, with a manifold on the intake and output to let me switch between input/output destinations. One input will pump from the HLT and output to the MLT. I'll valve the HLT input shut, and open the MLT input to circulate until sparging time. Gravity will feed the post-sparge sweet wort into the brew kettle, which will input into the pump again for a trip through a crossflow cooler and into a carboy for the yeast pitch and primary fermentation.

I've not yet made enough progress in Google Sketchup, a few of its features are driving me batty, to show all the components just yet. What I do have, is below.

Any feedback from folks that have done this before is definitely welcome. I spent a long time surrounded by the good-idea fairy (field-grade officers), so don't worry about discouraging me. I can take it.