paddyfunk

Well-Known Member

After a long hiatus from home brewing, I finally found some time to put together my herms system - thank you very much 20" inches of unplowable DC-area snow.

I have been brewing all-grain for about 5 batches and have been constantly frustrated by inconsistent mash temperatures, which have led to some malty-belgians and dry IPA’s = time for a herms.

My design is a basic e-HLT with a 1500 watt water heater element and 25 feet of 3/8” copper tubing. I went with 3/8” because: a) I already had the fittings and copper tubing; and b) the flow rate is more than enough for 5 gallon batches (I average about a gallon a minute). To improve heat transfer, I used a 30 gallon aquarium aerator to circulate water in my HLT. It did a great job and is a cheap alternative to a second March pump.

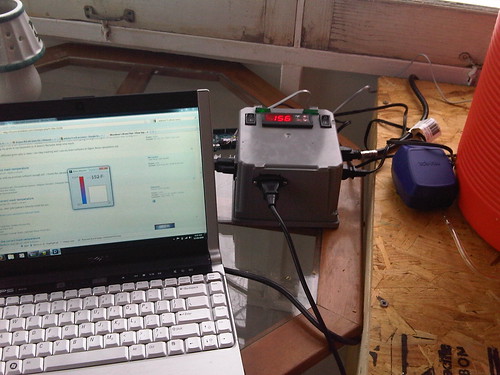

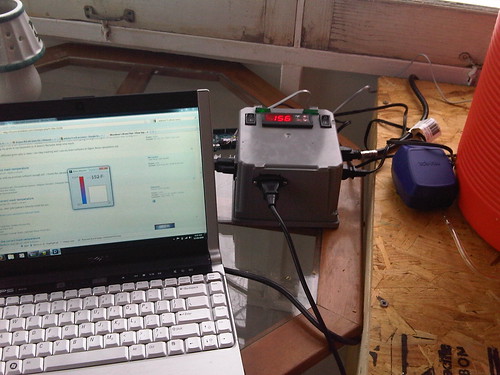

The HLT is controlled by a LOVE TS-13010, which I built into a project box that contains a 20 amp GFI. Again, I had a 20 amp GFCI lying around so why not. To monitor the MLT temperature, I used my Arduino and a LM34 sensor. The serial information is displayed on my laptop via a Processing script. It needs to be tweaked to average out the data a little bit better (maybe take the average of 5 seconds or so of readings).

My mash temperature remained rock solid through both brews this past weekend and I was able to ramp the temperature up at about 1.25 degrees per minute.

I have been brewing all-grain for about 5 batches and have been constantly frustrated by inconsistent mash temperatures, which have led to some malty-belgians and dry IPA’s = time for a herms.

My design is a basic e-HLT with a 1500 watt water heater element and 25 feet of 3/8” copper tubing. I went with 3/8” because: a) I already had the fittings and copper tubing; and b) the flow rate is more than enough for 5 gallon batches (I average about a gallon a minute). To improve heat transfer, I used a 30 gallon aquarium aerator to circulate water in my HLT. It did a great job and is a cheap alternative to a second March pump.

The HLT is controlled by a LOVE TS-13010, which I built into a project box that contains a 20 amp GFI. Again, I had a 20 amp GFCI lying around so why not. To monitor the MLT temperature, I used my Arduino and a LM34 sensor. The serial information is displayed on my laptop via a Processing script. It needs to be tweaked to average out the data a little bit better (maybe take the average of 5 seconds or so of readings).

My mash temperature remained rock solid through both brews this past weekend and I was able to ramp the temperature up at about 1.25 degrees per minute.