Here... I'll share my best, proven 1-Gallon recipe:

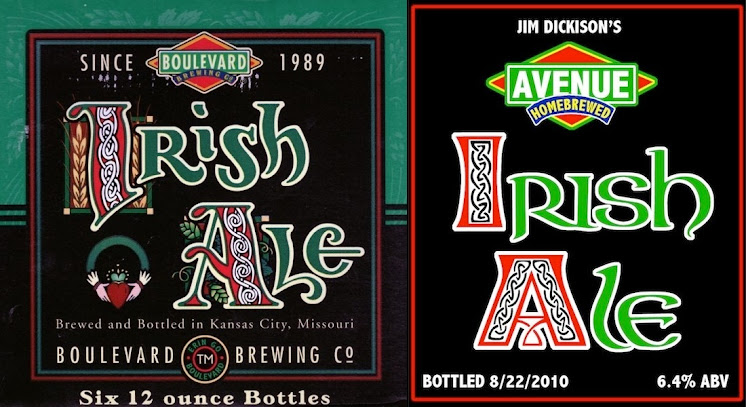

I originally developed this myself as a 5-gallon recipe. It is based on the very popular spring seasonal Irish Ale from Boulevard Brewing of Kansas City, MO. I got the list of grains and hops used along with gravity info (with no amounts or schedules!) from their website around 2006 or so, and used that to develop the recipe. Since then, they have drastically changed their recipe... Their current recipe for Boulevard Irish Ale looks absolutely nothing like this! Frankly, I think the old recipe was better! And I have it! This is one of the best-received beers I ever brewed!

In 2010, I scaled the recipe down to 1 gallon and brewed it using Brooklyn Brew Shop's 1 Gallon brewing instructions (they were pretty new back then!) Here it is:

Avenue Irish Ale

Grain Bill:

1.75 lb. Maris Otter (or regular 2-row)

0.5 lb. Munich Malt

3.0 oz. Wheat Malt

1.0 oz. Special B Caramel Malt

1.0 oz. Caramunich Type 1 Malt

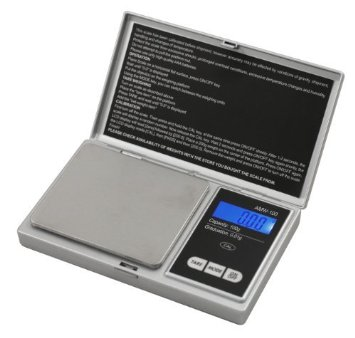

10.0 grams English Chocolate Malt (NOTE: GRAMS, not OZ. on this one! It doesn't seem like much, but it contributes a lot to the color!)

Hop Schedule:

3.0 grams Magnum (14% AA) @ 60 Minutes

3.0 grams Nugget (13% AA) @ 15 Minutes

3.0 grams East Kent Goldings (5% AA) @ 5 Minutes

Yeast:

White Labs WLP004 Irish Ale Yeast (Don't remember how much I used.

If I were brewing this today, I'd probably use 1/3-1/2 packet of Safale S-04

dry English Ale yeast for 1 gallon)

Mashed at about 152°F for 1 hour

Mashed out at 168°F for 10 minutes

Did the strainer-sparge method. 60 minute boil.

OG: 1.061

FG: 1.013

Color: 17 SRM

Bitterness: 38 IBU

ABV: 6.2% (Mine actually came out a bit higher)

Carbonation: 2.5 volumes CO2 (0.54 oz. corn sugar for 1 gallon)

I made a label for it, too (again... based on Boulevard's):

:rockin:

:rockin: