This came up in another thread, so last night while grilling I got my electric HLT going.

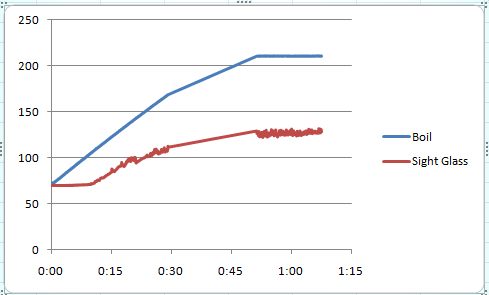

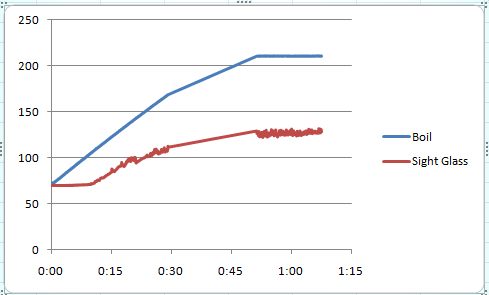

The question was this: during a boil, how hot does the liquid in the sight glass get. The hope was that it got high enough to kill the beer-ruining bacterial and wild yeast.

The result was that it never got there, and I'm surprised. Here's the data. 10 gallons, with pump running full bore to ensure good circulation. Bobby_M sight glass. One thermocouple is down in the middle of the boil, the other is slid into the sight glass, at about the 8g mark. The temp in the sight glass never got above about 130F.

BTW, my logging thermometer apparently somehow dropped about 20m of data from the 0:29 to 0:51. Or maybe I did that, der. That is why both graphs appear to be a straight line during that period.

The question was this: during a boil, how hot does the liquid in the sight glass get. The hope was that it got high enough to kill the beer-ruining bacterial and wild yeast.

The result was that it never got there, and I'm surprised. Here's the data. 10 gallons, with pump running full bore to ensure good circulation. Bobby_M sight glass. One thermocouple is down in the middle of the boil, the other is slid into the sight glass, at about the 8g mark. The temp in the sight glass never got above about 130F.

BTW, my logging thermometer apparently somehow dropped about 20m of data from the 0:29 to 0:51. Or maybe I did that, der. That is why both graphs appear to be a straight line during that period.