Ryanh1801

Well-Known Member

dang Im tiered started at 1 and just got done about 30 min ago .Brewed orfy's hobgoblin clone. Ended up with 65% efficiency, and have about decided thats as good as its gonna get with my LHBS crush. My mash ph was right on the money at 5.2. Mashed in at 122 let rest for 20 min. Removed 1/3 of the mash into pot, held at 155 then boiled for 20 min. added it back into the mash and got a temp of 148, a little low so I removed some more and heated it up. Only got to 153, I was wanting 156 but didn't feel like messing with it again. Removed another 1/3 of the mash and boiled for another 20 min. The resulting temp ended up being right above 160. BTW my grain to water ratio starting out was 1.3. ended up sparging with 5.8 gal of 170 degree water. I did two equal runnings. After pouring the water in I stirred the mash, then let rest 3 min. before starting first runnings. After I was done sparging I had a very, very full pot. I ended up having to boil for 1 hour before starting my hop schedule. Still ended up with around 5.5 gallons.

Mainly wondering if anyone could offer any advice on things I could do different. The one part that still confuses the hell out of me is the sparging. It seems that if you look at 3 different websites they all have a different was of Batch Sparging. Some say two equal runnings, other say to keep the mash toped up.

All in all i kind of liked the decoction mashing, and think im going to do it more often. Probably not going to brew again until I can buy my own grain crusher and maybe a fly sparging system. I liked the fact that I could say I only had 200 bucks in all my brewing equipment, but im starting to think I need to invest in some more equipment to make the best beer I can, Plus I really need a bigger pot and mash turn.

Any ways here are a few pics of todays brew.

This is heating up my first decoction.

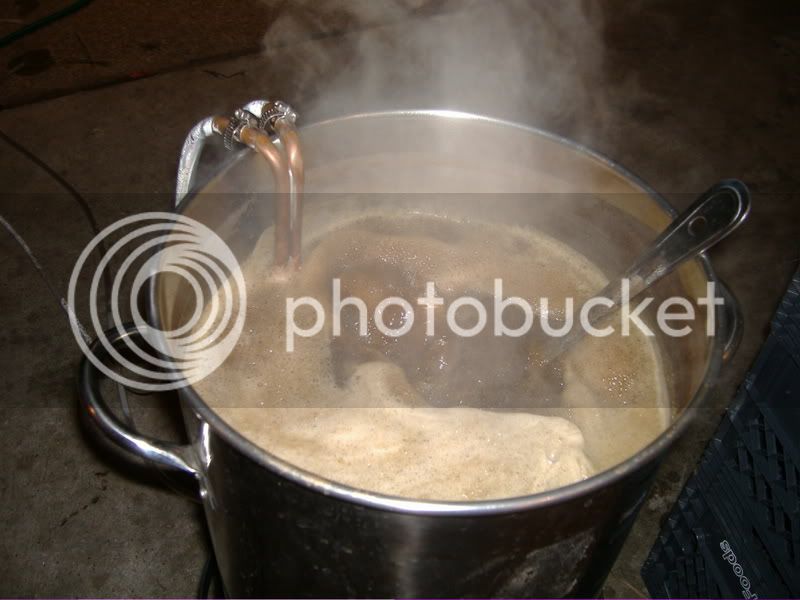

Starting the boil.

Mainly wondering if anyone could offer any advice on things I could do different. The one part that still confuses the hell out of me is the sparging. It seems that if you look at 3 different websites they all have a different was of Batch Sparging. Some say two equal runnings, other say to keep the mash toped up.

All in all i kind of liked the decoction mashing, and think im going to do it more often. Probably not going to brew again until I can buy my own grain crusher and maybe a fly sparging system. I liked the fact that I could say I only had 200 bucks in all my brewing equipment, but im starting to think I need to invest in some more equipment to make the best beer I can, Plus I really need a bigger pot and mash turn.

Any ways here are a few pics of todays brew.

This is heating up my first decoction.

Starting the boil.