yiannidoulis

New Member

- Joined

- Sep 25, 2008

- Messages

- 3

- Reaction score

- 0

Hi everyone, I've been watching the forum for two apple seasons now, and have been making cider for that time as well. I'm thinking of investing in some apple processing equipment, and wonder what you all think. We've got a great home brew store in town (F.H. Steinbart), and they sell both a yoke style and a ratchet style press in various sizes. I just rented the ratchet style and spent a frustrating evening trying to get juice out of a batch of cut up apples. 20 lbs, 2 hours, a 1 cup of juice later, I'm thinking I would need some form of crusher to really start pulping the apples. I've got 20# in the freezer, to see if that works to break the cell walls down, but with 200 lbs to go, and three more trees full of apples, that's not a viable solution

So, two days ago a tried a Champion juicer, which really mushed them up well, but too fine to put through a press, even with a bag (I think), and it was very slow as well.

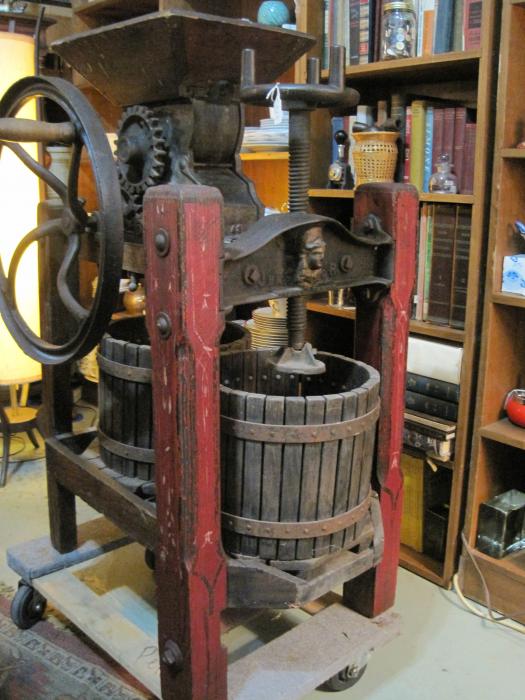

I've tried the old style wooden cider mill, with the electric crusher that dumps the pomace into the bucket, then slides down to the screw. OK, but that'll run almost a grand, and I don't have time to make one myself, though believe me it's tempting.

My ideal set up is something that takes a whole or quartered apple, turns it into the right stuff, and really squeezes the juice out of it, ideally without electricity, and without a whole lot of intermediate steps. The right tool for the right job, in other words.

Any ideas? Thanks a lot for all the education so far, by the way.

So, two days ago a tried a Champion juicer, which really mushed them up well, but too fine to put through a press, even with a bag (I think), and it was very slow as well.

I've tried the old style wooden cider mill, with the electric crusher that dumps the pomace into the bucket, then slides down to the screw. OK, but that'll run almost a grand, and I don't have time to make one myself, though believe me it's tempting.

My ideal set up is something that takes a whole or quartered apple, turns it into the right stuff, and really squeezes the juice out of it, ideally without electricity, and without a whole lot of intermediate steps. The right tool for the right job, in other words.

Any ideas? Thanks a lot for all the education so far, by the way.